20 Years Professional DC Geared Motor Manufacturer

ETONM provides a set of customization services, from design, sampling,production, to testing, etc. Here are some specification ranges:

- diameter: 6mm-50mm,

- voltage: under 24V,

- output speed: 0.1rpm-1500rpm,

- speed ratio: 3.4-5078,

- output torque: 0.1 kg.cm -400kg.cm.

20+ Years

of Industry Experience

10+ Million Units

Shipped Worldwide

100+ Global Clients

in Over 30 Countries

ISO-Certified

Manufacturing Processes

Innovative DC Motor Solutions Since 2004

Our Product Range

Specializing in Mini DC Motors & DC Gear Motors for Precision Applications

About ETONM MOTOR

ETONM MOTOR: Your Trusted Partner in Mini DC Motors and Gear Motor Innovation

Founded in 2004, ETONM MOTOR (Parent Company: Shenzhen Yitongda Electric Motor Co., Ltd.) is a global leader in the research, development, manufacturing, and sales of high-quality Mini DC Motors and DC Gear Motors. Our comprehensive product range includes:

- Spur Gear Motors

- Planetary Gear Motors

- Worm Gear Motors

With voltage ranges from 1V to 30V and motor diameters from φ8 to φ51mm, our solutions are engineered to meet the unique requirements of industries worldwide.

ODM, OEM and Customizations

Except Standard motors and gearbox, teams of Professional Engineers and Technicians offer you ODM, OEM and Customizations service.

One-stop purchase

ETONM MOTOR offers DC Gear Motors,DC Motors,Brushless Motor, Encoders. Here you can find motors 1-24VDC, diameter 8mm to 50mm, torque 0.1kg.cm to 500kg.cm.

Quality Assurance

With ISO90001, ISO14001, ROHS, CE, PATENTS, ETONM MOTOR is a long term partner for some FORTUNE GLOBAL 500 Companies.82% sales for US and EU. ETONM MOTOR is a reliable qualified motor supplier.

Versatile Motors Tailored for Diverse Applications

Empowering Industries with Precision DC Motor Solutions

At ETONM MOTOR, our Mini DC Motors and DC Gear Motors are engineered to meet the demanding requirements of various industries. From automation to medical technology, our solutions provide unmatched performance, durability, and precision.

Looking for a reliable motor for your next project? Explore how our solutions can drive innovation in your industry

Why ETONM MOTOR is Your Trusted Partner

Delivering Quality, Innovation, and Reliability in Every Motor

Proven Expertise

With over 20 years of experience in the design and production of Mini DC Motors and DC Gear Motors, we bring unparalleled knowledge and innovation to the industry.

Wide Product Range

From Spur Gear Motors to Planetary Gear Motors and more, our versatile product lineup caters to diverse industry needs with voltage options from 1V to 30V and diameters ranging from φ8 to φ51mm.

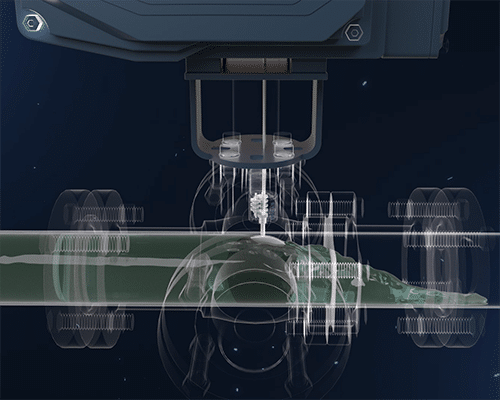

State-of-the-Art Manufacturing

Equipped with cutting-edge facilities and advanced machinery, we ensure that every motor meets stringent ISO-certified quality standards for performance and reliability.

Customization Capabilities

We specialize in creating tailored motor solutions to meet unique client specifications, including voltage, torque, speed, and size.

Global Client Base

Trusted by customers across industries such as medical devices, automation, automotive, and aerospace, we have built a reputation for delivering excellence worldwide.

Exceptional Customer Support

From initial consultation to after-sales service, our dedicated team ensures a seamless experience at every step of your project.

Partner with ETONM MOTOR for innovative and reliable motor solutions tailored to your needs.

Tailored Motor Solutions for Your Unique Needs

At ETONM MOTOR, we understand that every project is unique. That’s why we specialize in providing customized Mini DC Motors and DC Gear Motors tailored to meet the precise requirements of your application. From design to delivery, our team works closely with you to ensure the perfect solution.

Our Customization Capabilities

- Voltage & Power Adjustments: Tailor motor specifications from 1V to 30V to suit your device’s power needs.

- Size & Form Factor: Flexible diameters ranging from φ8mm to φ51mm to fit compact or large-scale applications.

- Torque & Speed Optimization: Customize torque and speed for enhanced performance in specific environments.

- Material Selection: Choose materials that meet your durability, weight, or environmental requirements.

- Gear Configuration: Design specific gear types, including Spur, Planetary, or Worm Gear Motors, for optimal functionality.

- Connectors & Assembly Options: Integrate custom connectors, wiring, or mounting solutions to simplify implementation.

At ETONM MOTOR, we don’t just build motors – we create solutions designed for your specific applications.

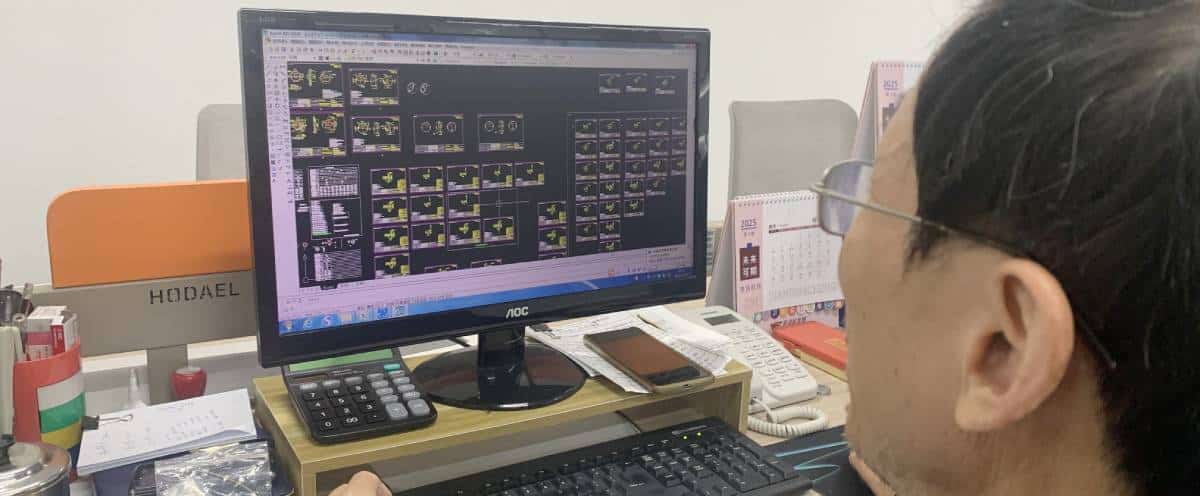

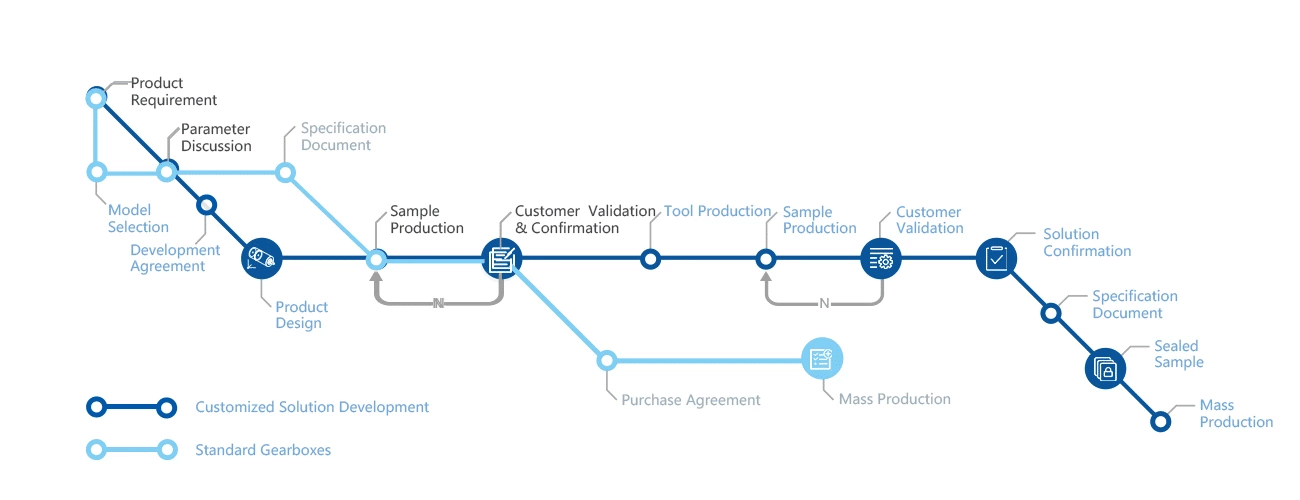

Streamlined Process for Customized Motor Development

From concept to mass production, we ensure precision, efficiency, and customer satisfaction.

At ETONM MOTOR, our custom motor development process is designed to be transparent, collaborative, and efficient. Each step ensures we meet your unique requirements while maintaining the highest quality standards.

Development Steps

Step 1

Product Requirement & Parameter Discussion

Collaborate with our experts to define your motor’s specifications and functional requirements.

Step 2

Model Selection & Development Agreement

Choose the best motor model, finalize the design concept, and establish a clear development agreement.

Step 3

Product Design & Specification Document

Our engineering team creates a detailed design, followed by documentation of all specifications for your approval.

Step 4

Sample Production & Validation

Produce a prototype sample for testing and validation, ensuring the motor meets your exact needs.

Step 5

Tool Production & Final Validation

Once the sample is approved, we begin tooling production and conduct final validation with your team.

Step 6

Mass Production

With your approval, we proceed to full-scale manufacturing, delivering consistent, high-quality motors on time.

Partner