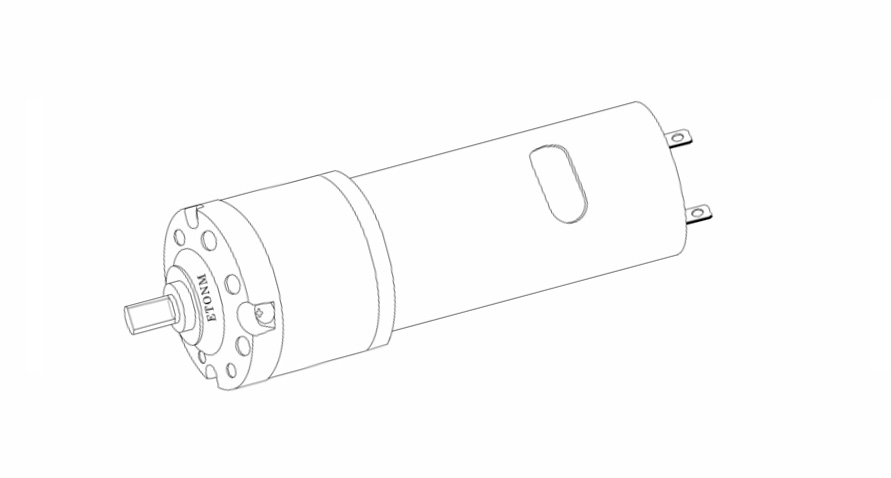

"Explore how shaft design affects 12V DC motor performance with dual shaft, long shaft, and 8mm options from Etonm Motor."

Table of Contents

Why Shaft Design Matters for Your 12V DC Motor

A 12V DC motor powers countless devices—robots gliding across floors, vending machines dispensing snacks, or smart home systems working quietly in the background. These motors are small but mighty, and one often-overlooked detail can make a big difference: the shaft design. Far more than just a metal extension, the shaft determines how torque is delivered, how the motor fits into your setup, and how reliably it performs under stress. Whether you need a 12 volt DC motor dual shaft for a bidirectional task or a 12V DC motor with a long shaft for precision work, the right design can elevate your project. At Etonm Motor, we’ve seen how a tailored shaft turns ideas into reality. Let’s explore why this matters and what options you have.

Exploring Custom Shaft Options for 12V DC Motors

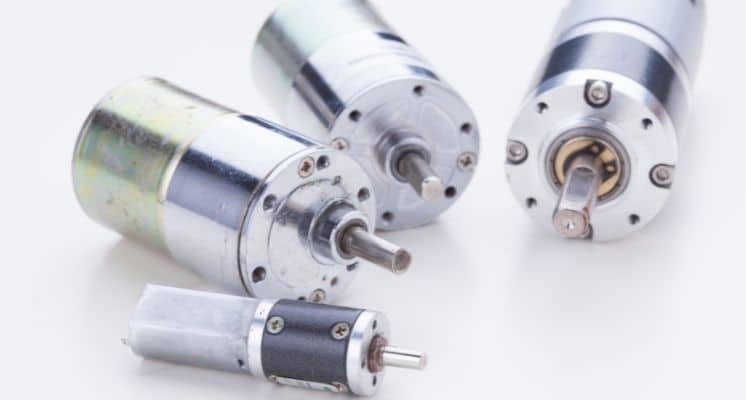

Choosing the right shaft for a 12V DC motor means understanding your options. Etonm Motor offers custom designs like dual shaft, long shaft, and 8mm shaft, each with unique strengths suited to different needs. Here’s a closer look at what they bring to the table.

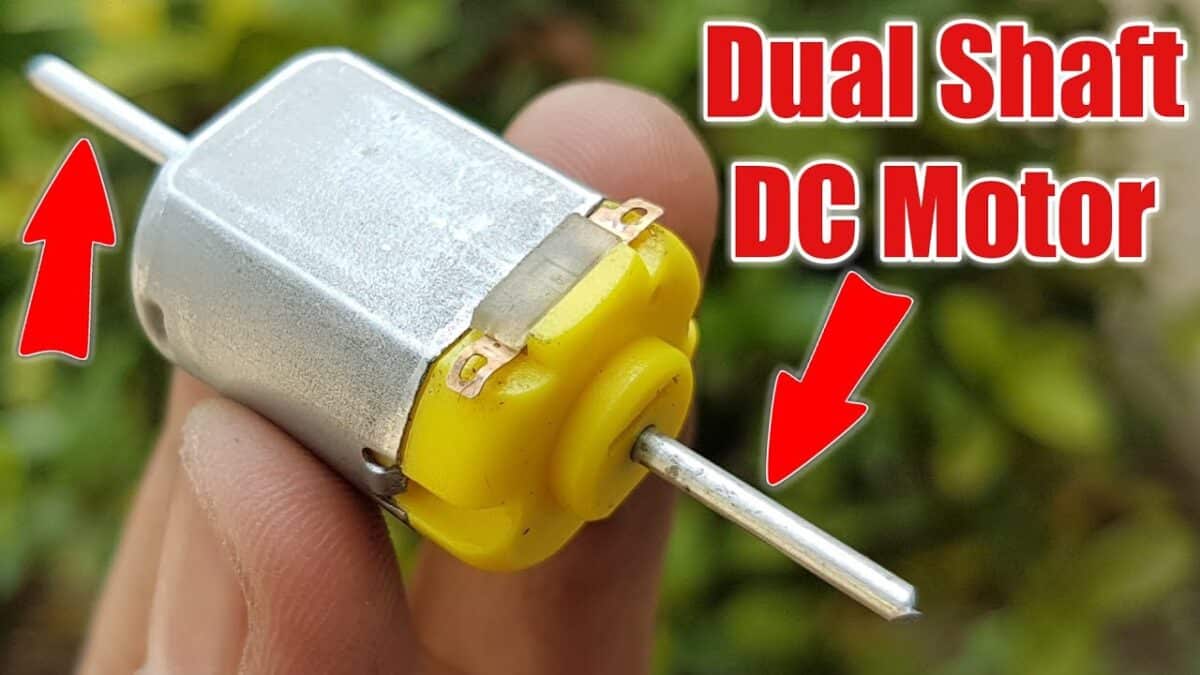

The Benefits of a 12 Volt DC Motor Dual Shaft

A 12 volt DC motor dual shaft delivers power from both ends, offering flexibility for multi-tasking projects. This design is popular in robotics, where one shaft might drive wheels while the other adjusts a sensor arm. It’s also useful in smart home devices, like automated blinds requiring dual outputs. By handling two functions with one motor, it saves space and simplifies your build—ideal when efficiency is a priority.

12V DC Motor with Long Shaft: Precision and Reach

For setups needing extra reach, a 12V DC motor with a long shaft is a practical choice. The extended length connects components in tight or recessed spaces, such as precision machinery or vending machine dispensers. This design maintains steady torque delivery and can improve installation flexibility by up to 15% in constrained layouts, making it a go-to for complex applications.

Why Choose a 12V DC Motor 8mm Shaft?

A 12V DC motor 8mm shaft strikes a balance between strength and compatibility. With an 8mm diameter, it supports moderate loads while fitting standard couplings and mounts. It’s widely used in electric valves and medical devices, where precision and reliability are critical. This option adapts easily to various setups, offering a dependable solution without extensive modifications.

Real-World Applications of Custom Shaft Motors

So, how do these designs perform in practice? Custom shaft motors solve real challenges across industries, and Etonm Motor has the experience to prove it. Here are two examples that highlight their impact.

Dual Shaft Motors in Robotics

In robotics, a 12 volt DC motor dual shaft simplifies designs that need multiple outputs. Picture a small warehouse robot: one shaft powers its wheels for navigation, while the other moves a scanning arm. This reduces the need for extra motors, cutting weight and space—key factors for efficient prototypes in automation or home robotics.

Long Shaft Motors in Sanitary Dispensers

Sanitary dispensers, like soap or sanitizer units, benefit from a 12V DC motor with a long shaft. The extended shaft reaches deep into the housing to drive the dispensing mechanism, ensuring consistent flow. One client found that switching to this design reduced jamming by 20%, showing how a tailored shaft enhances everyday reliability.

How to Choose the Right Shaft for Your 12V DC Motor

With these applications in mind, how do you pick the best shaft for your project? It comes down to a few practical considerations. Here’s a guide to help you decide.

Shaft Length: Finding the Right Fit

Shaft length affects how your motor integrates. A 12V DC motor with a long shaft suits setups needing depth, like vending machines, while a shorter shaft fits compact designs, such as small robots. Measure your space and add a 10-15% buffer to the minimum length for alignment flexibility.

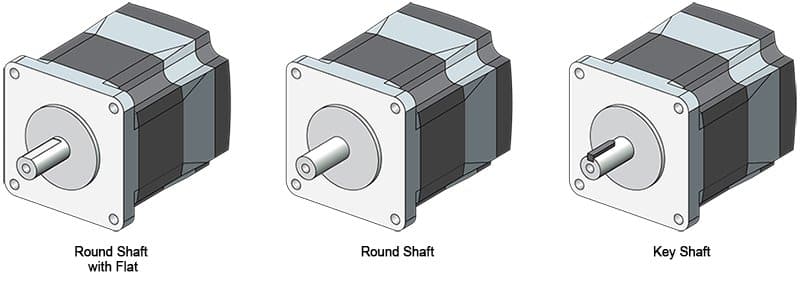

Shaft Diameter: Balancing Strength and Compatibility

Diameter impacts durability and fit. A 12V DC motor 8mm shaft handles moderate loads and pairs well with standard parts, making it versatile for valves or medical tools. Heavier tasks might need a thicker shaft, while lighter ones can use a slimmer option. Match it to your load and coupling specs.

Key Questions to Guide Your Decision

Ask these three questions:

- What’s the load? Heavier loads favor thicker or dual shafts, like a 12 volt DC motor dual shaft.

- What’s the speed? High RPMs may need a shorter shaft to limit vibration.

- What’s the environment? Harsh conditions might require a sealed design, influencing shaft choice.

For more details, visit Etonm Motor’s product page.

Tailored 12V Motor Solutions with Etonm Motor

Shaft design is a game-changer for 12V DC motor performance, whether it’s the dual output of a 12 volt DC motor dual shaft, the reach of a 12V DC motor with a long shaft, or the stability of a 12V DC motor 8mm shaft. At Etonm Motor, we craft custom solutions to meet your specific needs, from smart home systems to robotics. Our expertise ensures you get a motor that fits perfectly and performs reliably. Ready to start? Explore our custom motor options or contact us to bring your vision to life.

Explore Our 12v DC Motors

Related Reading

- 12V DC Fan Motor Guide

- 12V DC Motor Speed Controllers: How They Work & Setup Tips

- 12V DC Motor Guide: From Basics to Uses

- 12V Gear Motor Guide: Worm vs Planetary Gears

- 12V DC Motor with Encoder: Precision Guide for Beginners

- 12V vs 24V DC Motors: How to Choose Your Voltage

- DC Motor Types: A Guide to Choosing the Right Model

- Mini DC Motor Selection Guide

- How to Choose the Right Mini DC Motor Voltage

- Gear Motor vs DC Motor vs Stepper Motor: Key Differences

- How Does a DC Motor Work? A Simple Guide by Etonm Motor

- DC Motor Parameters You Need to Know Before Choosing

- What Is DC Motor Torque? A Simple Guide by Etonm Motor

- Custom Control: Pairing 12V DC Motors With Speed And Encoder Accessories