Explore the world of 12V high torque DC motors and find the perfect power solution for your robotics, automation, or industrial project. This comprehensive guide covers everything from torque specifications to application-specific requirements.

Table of Contents

In the world of mechanical engineering and electronic applications, few components are as versatile and essential as the 12V high torque DC motor. These compact powerhouses drive everything from sophisticated robotics to everyday household appliances, offering remarkable strength in relatively small packages.

Understanding High Torque DC Motors at 12V

What Makes a DC Motor "High Torque"?

High torque motors are engineered to deliver substantial twisting power even at lower RPMs. While a typical 12V DC motor might generate 0.5-2 Nm of torque, high torque variants can deliver anywhere from 3-20 Nm or more, making them ideal for applications requiring force rather than velocity.

The secret behind this enhanced power often lies in the motor’s internal design features:

- Stronger permanent magnets

- More efficient winding patterns

- Higher copper content in the armature

- Specialized gear reduction systems

Most high torque 12V motors incorporate planetary gear systems or worm gear mechanisms that trade rotational speed for increased torque output, allowing relatively small motors to perform tasks that would otherwise require much larger units.

The Advantages of 12V Power Supply

The 12-volt standard has become ubiquitous for good reasons:

- Versatile compatibility with numerous power sources, including vehicle electrical systems, solar setups, and standard power supplies

- Efficient power delivery with reasonable current requirements, meaning thinner wires and less heat generation

- Balanced safety profile with lower risks than higher voltage alternatives while delivering sufficient power for most torque-demanding tasks

Torque vs. Speed: Finding the Right Balance

- Does your application require maintaining force while stationary?

- Is your priority moving heavy loads, even if slowly?

- Do you need precise positioning under varying load conditions?

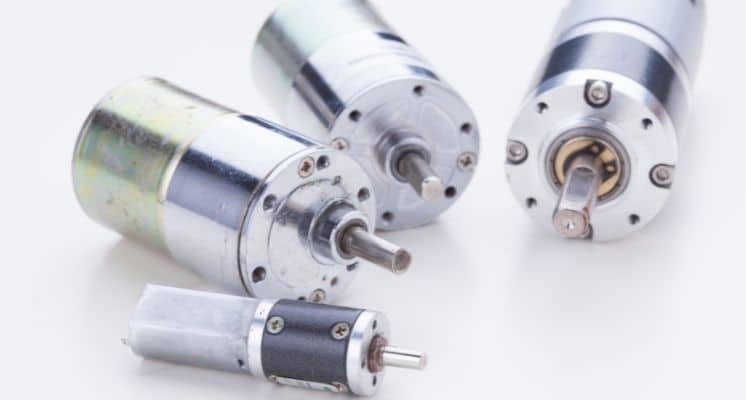

Types of 12V High Torque Motors

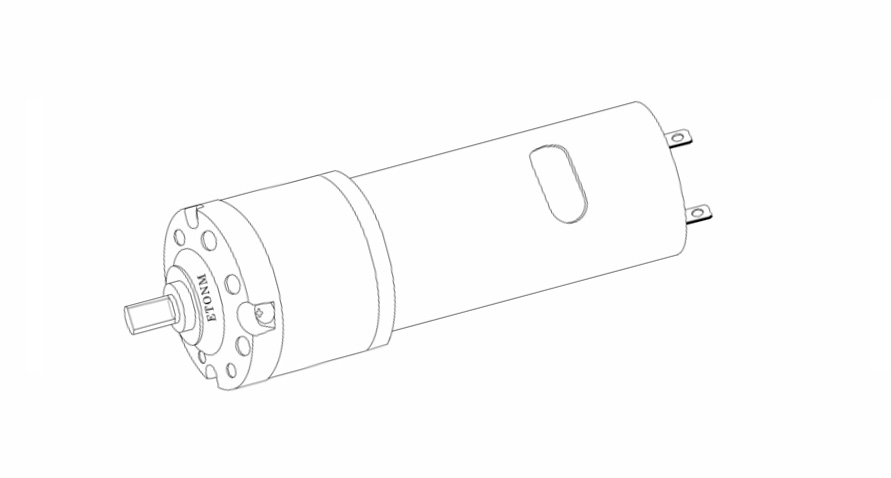

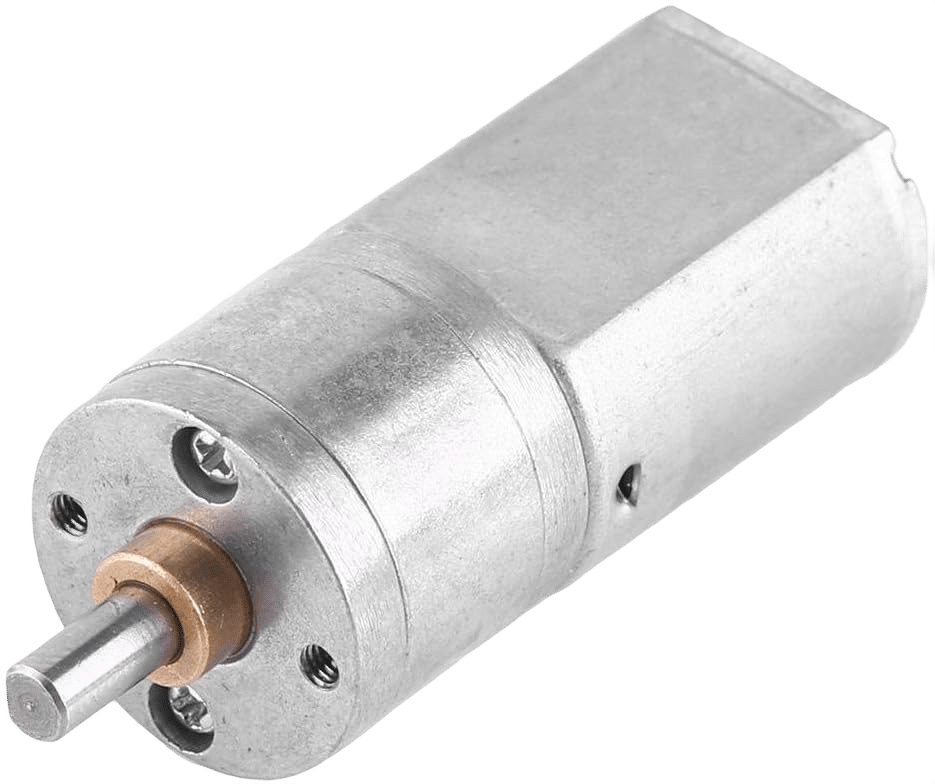

Planetary Gear Motors for Maximum Torque

Planetary gear motors contain a central “sun” gear surrounded by orbiting “planet” gears, all enclosed within an outer “ring” gear. This ingenious design offers several advantages:

- Load distribution across multiple gear teeth simultaneously

- Compact coaxial arrangement keeping motor and output shaft aligned

- Reduced vibration and noise compared to other high-torque solutions

- Remarkable reduction ratios (often 100:1 or higher) within a small footprint

These characteristics make planetary gear motors perfect for precision applications where space is limited but power demands are high.

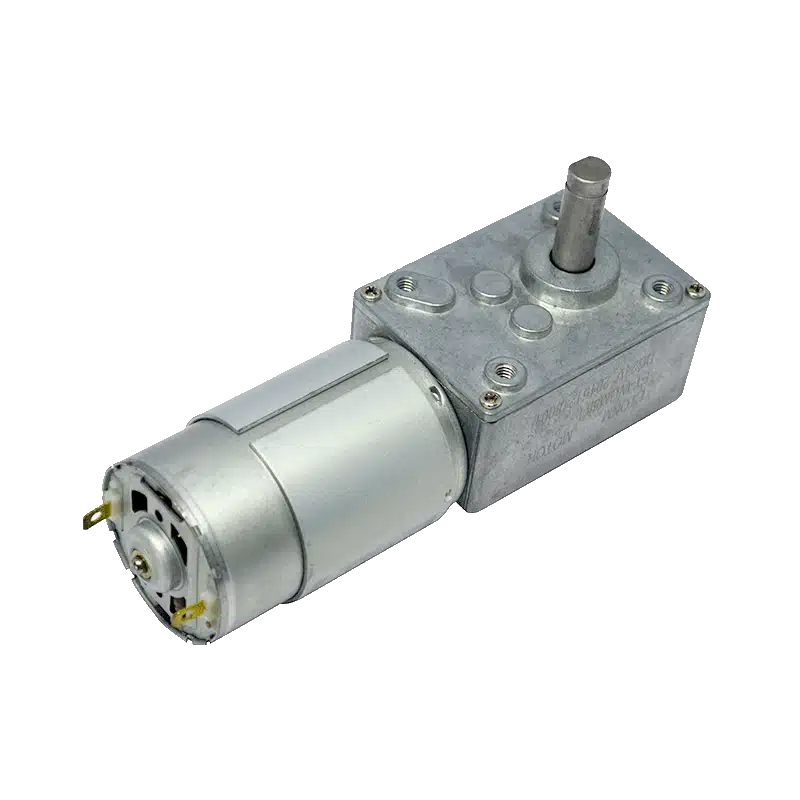

Worm Gear Motors for Reliable Power

Worm gear systems feature a screw-like “worm” that meshes with a circular gear wheel, creating several unique advantages:

- High reduction ratios (often 20:1 to 100:1) in a single gear stage

- Self-locking capability that prevents backward rotation when unpowered

- Right-angle power transmission for solving challenging space constraints

This natural braking capability proves invaluable in applications like lifting mechanisms, security systems, and positioning equipment where maintaining position without power is essential.

Brushless DC Motors for Efficiency and Longevity

For applications requiring both high torque and extended operational life, 12V brushless DC motors (BLDC) represent the cutting edge of motor technology with:

- Elimination of wear-prone brushes, dramatically extending service life

- Higher efficiency (85-90% compared to 60-75% for brushed alternatives)

- Sophisticated speed and torque management through electronic control

- Extended battery life in portable applications

While brushless motors typically cost more initially than brushed alternatives, their efficiency and reliability often make them the most economical choice over the complete lifecycle of a product.

Key Applications for 12V High Torque Motors

Robotics and Automation

In robotics and automation, precise movement control combined with significant force makes high torque motors ideal for:

- Robotic arms and grippers that manipulate objects while maintaining precise positioning

- Autonomous mobile robots navigating uneven terrain or climbing inclines

- Industrial automation systems in conveyor systems and material handling equipment

The compact nature of high torque 12V motors allows designers to create increasingly sophisticated systems without bulk and weight penalties.

Smart Home and Security Systems

The growing smart home sector leverages 12V high torque motors in numerous applications:

- Motorized window treatments for heavy blinds, shades, and curtains

- Security applications like automatic door locks, gates, and barriers

- Smart furniture including height-adjustable desks and motorized TV lifts

- Climate control systems for precisely positioning dampers, vents, and valves

The self-locking qualities of certain motor types prevent unwanted movement when unpowered, ensuring security and consistent control.

Industrial Equipment and Vending Machines

In industrial applications, reliability under continuous use makes quality 12V high torque motors indispensable:

- Vending machines requiring motors powerful enough to move merchandise of varying weights

- Electric valves and flow control systems managing liquids and gases across industrial processes

- Industrial testing equipment applying consistent forces across repeated test cycles

- Material handling equipment like conveyor diverters and sorting mechanisms

Their ability to start reliably under load and respond quickly to control signals improves throughput and reduces failures in high-volume operations.

Medical Devices and Precision Instruments

Medical and precision instrument sectors present perhaps the most demanding applications:

- Surgical robots and powered medical tools requiring exceptional precision

- Patient positioning systems in medical imaging equipment

- Laboratory automation for sample handling and testing equipment

- Optical equipment from automated microscope stages to camera positioning systems

The quiet operation and precision of quality motors improves results while enhancing patient comfort during medical procedures.

How to Select the Right 12V High Torque Motor

Calculating Your Torque Requirements

The most fundamental step in motor selection is accurately determining required torque:

- Identify the maximum load your motor must move or hold

- Calculate torque by multiplying force by distance from center of rotation

- Remember that static torque typically requires 1.5-3 times more than maintaining movement

- Add a safety factor of at least 30% for most applications

For example:

- Robot arm lifting 2kg at 25cm: Force = 2kg × 9.8m/s² = 19.6N

- Torque = 19.6N × 0.25m = 4.9Nm

- With safety factor: Required torque = 4.9Nm × 1.3 = 6.37Nm

Remember that motor specifications typically list both continuous torque (sustainable indefinitely) and peak torque (available briefly).

Important Specifications to Consider

Beyond raw torque, several other specifications affect motor suitability:

- Speed requirements (higher torque generally comes at the expense of speed)

- Duty cycle (percentage of time the motor will be actively running versus resting)

- Physical dimensions and mounting options

- Environmental factors (temperature range, moisture exposure, contaminants)

- Control requirements (simple on/off vs. precise speed or position control)

- Noise and vibration (particularly important in consumer or medical products)

- Efficiency and power consumption (affecting battery life and operating costs)

Matching Motor Type to Application

Different motor technologies excel in different scenarios:

| Planetary Gear | High torque in compact packages, efficiency | Higher cost, complex construction |

| Worm Gear | Self-locking applications, 90° power transmission | Lower efficiency, higher wear rates |

| Brushless | Continuous-duty, long life, sophisticated control | Complex driver electronics, higher cost |

| Brushed with Reduction | Budget-conscious applications, simpler controls | Shorter service life, lower efficiency |

When possible, test prototype motors under real-world conditions before finalizing designs—particularly for high-volume products where incorrect specification can be costly.

Customization Options for Specialized Needs

Modifying Gear Ratios for Optimal Performance

Custom gear ratios allow engineers to precisely balance torque and speed for maximum efficiency. Beyond simple ratio adjustments, specialized features include:

- Backlash-minimized designs for precise bidirectional movement

- Reinforced gears for handling impact loads or frequent start/stop cycles

- Materials optimized for extreme temperatures

- Anti-vibration gear profiles minimizing noise in sensitive environments

These optimizations can increase system efficiency by 5-15% compared to generic solutions.

Integrating Control Systems for Precision

Modern applications benefit from integrated control systems combining motor, gearing, and electronics into unified modules with features like:

- Closed-loop position feedback using Hall sensors or encoders

- Current limiting to protect against overload conditions

- Soft-start capabilities reducing mechanical stress

- Programmable acceleration/deceleration profiles

- Communication interfaces for seamless system integration

Physical integration reduces wiring complexity, improves reliability, and often reduces overall footprint compared to separate components.

Adapting Motors for Challenging Environments

- Moisture and dust protection with enhanced sealing (IP65, IP67, or IP68 ratings)

- Chemical resistance through specialized housings and materials

- Temperature extremes addressed with special lubricants and materials

- EMC requirements met with customized shielding and filtering

- Custom shaft configurations allowing direct interface with application-specific mechanisms

Etonm Motor's Custom High Torque Solutions

Our Engineering Expertise

Etonm Motor’s development team combines theoretical expertise with hands-on manufacturing knowledge to create solutions that perform reliably in real-world applications. Our engineering-first approach begins with a collaborative consultation process to understand underlying application requirements.

The company’s vertically integrated manufacturing capabilities enable rapid prototyping and iterative refinement—critical advantages when developing custom solutions. This allows clients to test designs in their actual applications before committing to production quantities.

Case Studies: Successful Implementations

Medical Laboratory Equipment: Etonm developed a custom brushless motor with integrated position feedback maintaining accuracy within ±0.1 degrees. The new motors reduced positioning errors by 87% while extending maintenance intervals from quarterly to annually.

Smart Home Application: For motorized window treatments, Etonm created a solution combining quiet operation (below 40dB) with reliable performance, integrated obstacle detection, and networked control capabilities.

Industrial Valve Systems: Etonm delivered a high-efficiency brushless motor with a custom-sealed housing (IP67 protection) and thermal compensation algorithms maintaining consistent performance from -20°C to +60°C, reducing maintenance issues by 80%.

Working with Etonm for Your Specific Needs

Developing a custom solution follows several key phases:

- Initial consultation focusing on understanding the broader application context

- Detailed proposal outlining the recommended approach and specifications

- Prototype development for testing in actual applications

- Collaborative refinement ensuring the final solution precisely meets requirements

- Flexible manufacturing from small specialty batches to high-volume production

- Ongoing support addressing any issues during integration or field use

By combining engineering expertise with manufacturing capability and a collaborative approach, Etonm has established itself as a preferred partner for companies requiring custom 12V high torque motor solutions.

Conclusion and Next Steps

The world of 12V high torque DC motors offers remarkable capabilities for designers and engineers across countless industries. Selecting the right motor—whether standard or custom—requires balancing numerous factors to achieve optimal performance.

For many standard applications, off-the-shelf motors provide excellent performance at reasonable cost. As applications become more specialized, however, customized solutions can transform challenging design problems into practical realities.

At Etonm Motor, we’ve built our reputation on delivering both standard and custom solutions that consistently exceed expectations. Our comprehensive product range spans from general-purpose motors to highly specialized designs for demanding applications.

For your next project, we invite you to engage with our engineering team early in your design process. Begin by defining your requirements as precisely as possible—not just torque and speed, but also environmental conditions, space constraints, control needs, and operational expectations.

Whether you’re developing an innovative new product or enhancing an existing design, the right 12V high torque motor can make all the difference in achieving your performance goals. Contact our engineering team today to discuss your specific requirements and discover how Etonm Motor can help transform your performance challenges into competitive advantages.

Explore Our 12v DC Motors

Related Reading

- High Torque Gear Motors: Unleashing 12V Power for Robotics

- DC Motor Speed Controller 12V Basics: From Brushed to BLDC

- Custom Control: Pairing 12V DC Motors with Speed and Encoder Accessories

- 12V DC Motor High Torque High RPM: Torque vs. Speed

- Low RPM Brushless Motor: Technical Specs & Customization

- How to Choose the Right Mini DC Motor Voltage

- What Is DC Motor Torque? A Simple Guide by Etonm Motor

- High Torque 12V DC Motor 2000 RPM | Custom 8mm Shaft Motors

- 12V Low Speed High Torque Motor: Ideal For DIY Projects

- Small But Mighty: Mastering Small High Torque 12V Motors