Discover why 12V low speed high torque motors are the perfect choice for your DIY projects. Learn how gear reduction enhances torque and explore their applications in lifts, model cars, and more.

Table of Contents

When it comes to DIY projects, having the right motor can make all the difference. Whether you’re building a lift mechanism, a model car, or a robotic arm, one type of motor stands out for its versatility and power: the 12V low speed high torque motor. These motors are designed to deliver exceptional performance at lower speeds, making them ideal for applications where precision and strength are key.

But what makes a 12V DC motor with high torque and low RPM so special? The secret lies in its ability to combine controlled speed with robust power output. Unlike standard motors that prioritize high speed, these motors are engineered to handle heavy loads without compromising efficiency. This makes them a favorite among DIY enthusiasts and professionals alike.

At Etonm Motor, we specialize in crafting high-quality 12 volt motors with high torque and low RPM, perfect for a wide range of applications. From smart home devices to robotics and beyond, our motors are built to meet the demands of your most ambitious projects.

In this article, we’ll explore why 12V low speed high torque motors are a game-changer for DIYers, how they work, and how to choose the right one for your needs. Let’s dive in and discover how these motors can take your projects to the next level!

How Gear Reduction Enhances Torque

When it comes to understanding why 12V low speed high torque motors are so effective, the magic lies in a simple yet powerful concept: gear reduction. This mechanism is the key to transforming a standard motor into a powerhouse capable of handling heavy loads with ease.

What is Gear Reduction?

Gear reduction is a process where a system of gears is used to decrease the output speed of a motor while simultaneously increasing its torque. Think of it like riding a bicycle: when you shift to a lower gear, it becomes easier to pedal uphill, even though you’re moving slower. Similarly, gear reduction allows a 12V DC motor to deliver more rotational force (torque) at lower speeds (RPM).

How Does It Work?

In a 12V low speed high torque motor, the motor’s initial high-speed rotation is passed through a series of gears. Each gear stage reduces the speed while multiplying the torque. For example, if a motor spins at 1,000 RPM but produces only a small amount of torque, a gear reduction system can lower the RPM to 100 while increasing the torque tenfold. This makes the motor perfect for applications where slow, powerful movements are required, such as lifting heavy objects or driving a model car up a steep incline.

Why Does This Matter for DIY Projects?

For DIY enthusiasts, this combination of low RPM and high torque is a game-changer. It means you can use a compact, energy-efficient 12 volt motor to perform tasks that would typically require a much larger, more power-hungry motor. Whether you’re building a robotic arm that needs precise, powerful movements or a vending machine that requires consistent, reliable operation, a 12V DC motor with high torque and low RPM offers the perfect balance of control and strength.

Real-World Example: Lifting Mechanisms

Imagine you’re building a motorized lift for a small-scale project. A standard high-speed motor might struggle to lift the load, but a 12V low speed high torque motor with gear reduction can handle the task effortlessly. The slower speed ensures smooth, controlled movement, while the increased torque provides the necessary power to lift the weight without straining the motor.

In summary, gear reduction is the unsung hero behind the impressive performance of 12V low speed high torque motors. By understanding this principle, you can better appreciate why these motors are such a versatile and reliable choice for your DIY projects.

DIY Applications of 12V Low Speed High Torque Motors

One of the most exciting aspects of 12V low speed high torque motors is their versatility. These motors are not just powerful—they’re also incredibly adaptable, making them a go-to choice for a wide range of DIY projects. Let’s explore some of the most popular applications where these motors shine.

Lift Mechanisms

Whether you’re building a small elevator for a dollhouse or a motorized lift for a workbench, a 12V DC motor with high torque and low RPM is an excellent choice. The high torque ensures that the motor can handle the weight of the load, while the low speed allows for smooth, controlled movement. This combination is particularly important in applications where safety and precision are critical.

For example, if you’re designing a lift for a homemade 3D printer or a camera slider, a 12 volt motor high torque low rpm can provide the steady, reliable performance you need. The motor’s ability to operate at low speeds without losing power ensures that your lift moves smoothly and accurately, even under heavy loads.

Model Cars and Robotics

If you’re into building model cars, robots, or other moving creations, a 12V low speed high torque motor can take your projects to the next level. These motors are ideal for driving wheels, arms, or other moving parts, thanks to their ability to deliver consistent power at controlled speeds.

For instance, in a model car, a 12V DC motor high torque low rpm can provide the necessary traction to climb steep inclines or navigate rough terrain. Similarly, in robotics, these motors are perfect for joints and limbs that require precise, powerful movements. The low speed ensures that your robot moves smoothly, while the high torque allows it to carry payloads or perform tasks that require strength.

Home Automation and Smart Devices

The rise of smart home technology has created a growing demand for compact, efficient motors that can operate quietly and reliably. A 12V low speed high torque motor is an excellent fit for applications like automatic door openers, window blinds, or even smart pet feeders.

For example, imagine building a motorized window blind system that opens and closes at specific times of the day. A 12 volt motor high torque low rpm can provide the quiet, consistent operation needed for this type of application, ensuring that your blinds move smoothly without jerking or stalling.

Vending Machines and Dispensers

If you’re working on a vending machine, sanitizer dispenser, or similar device, a 12V DC motor with high torque and low RPM can deliver the reliability and power you need. These motors are perfect for driving mechanisms that require precise, repeatable movements, such as dispensing products or rotating a carousel.

For instance, in a DIY vending machine, a 12V low speed high torque motor can ensure that the machine dispenses items consistently and without jamming. The motor’s ability to operate at low speeds while maintaining high torque makes it an ideal choice for this type of application.

Tips for Choosing the Right 12V Low Speed High Torque Motor

Now that you’ve seen the incredible versatility of 12V low speed high torque motors, you might be wondering how to choose the perfect one for your DIY project. Selecting the right motor involves balancing several factors, including speed, torque, and compatibility with your application. Here are some practical tips to help you make the best choice.

Balancing RPM and Torque

One of the most important considerations when choosing a motor is finding the right balance between RPM (revolutions per minute) and torque. While a 12V DC motor with high torque and low RPM is ideal for many applications, the specific requirements of your project will determine the exact specifications you need.

Low RPM for Precision: If your project requires slow, controlled movements—such as in a lift mechanism or robotic arm—opt for a motor with a lower RPM. This ensures smooth operation and reduces the risk of jerky or uneven motion.

High Torque for Power: For tasks that involve lifting heavy loads or overcoming resistance, prioritize torque. A 12 volt motor high torque low rpm will provide the strength needed to handle demanding applications without straining the motor.

Key Features to Look For

When shopping for a 12V low speed high torque motor, keep an eye out for the following features to ensure you’re getting a high-quality, reliable product:

Durability: Look for motors made from robust materials that can withstand frequent use and harsh conditions. This is especially important for outdoor projects or applications involving heavy loads.

Efficiency: A motor that operates efficiently will consume less power and generate less heat, extending its lifespan and reducing energy costs.

Compatibility: Ensure the motor is compatible with your power supply and control systems. For example, if you’re using a microcontroller like Arduino, verify that the motor can be easily integrated.

Noise Level: For applications in quiet environments, such as smart home devices, choose a motor that operates quietly. Gear motors, like those offered by Etonm Motor, are often designed to minimize noise.

Size and Weight: Consider the physical dimensions and weight of the motor, especially if you’re working on a compact or portable project.

Real-World Example – Choosing a Motor for a Model Car

Let’s say you’re building a model car that needs to climb steep inclines and navigate rough terrain. Here’s how you might approach selecting the right motor:

Torque Requirements: Since the car needs to overcome resistance, prioritize a 12V DC motor high torque low rpm with sufficient torque to handle the load.

Speed Considerations: While high speed might seem appealing, a lower RPM will provide better control and stability, especially on uneven surfaces.

Durability: Choose a motor designed for rugged use, as model cars often encounter bumps and shocks.

By carefully evaluating these factors, you can select a motor that meets your project’s specific needs and ensures reliable performance.

Explore Etonm Motor’s Range of 12V Low Speed High Torque Motors

When it comes to finding the perfect 12V low speed high torque motor for your DIY projects, Etonm Motor stands out as a trusted partner. With years of expertise in designing and manufacturing high-quality motors, we offer a wide range of options tailored to meet the unique needs of hobbyists, engineers, and innovators alike.

Why Choose Etonm Motor?

Customization Options: At Etonm Motor, we understand that no two projects are the same. That’s why we offer customizable solutions, allowing you to select the exact specifications—such as RPM, torque, and size—that match your requirements.

High-Quality Materials: Our motors are built to last, using durable materials that ensure reliable performance even in demanding applications.

Wide Range of Applications: Whether you’re working on a smart home device, a robotic arm, or a vending machine, our 12V DC motor high torque low rpm options are designed to deliver exceptional results.

Expert Support: Our team of experts is always ready to assist you in selecting the right motor or troubleshooting your project. We’re passionate about helping you bring your ideas to life.

Popular Products for DIY Enthusiasts

Here are some of our most popular 12 volt motor high torque low rpm options that are perfect for DIY projects:

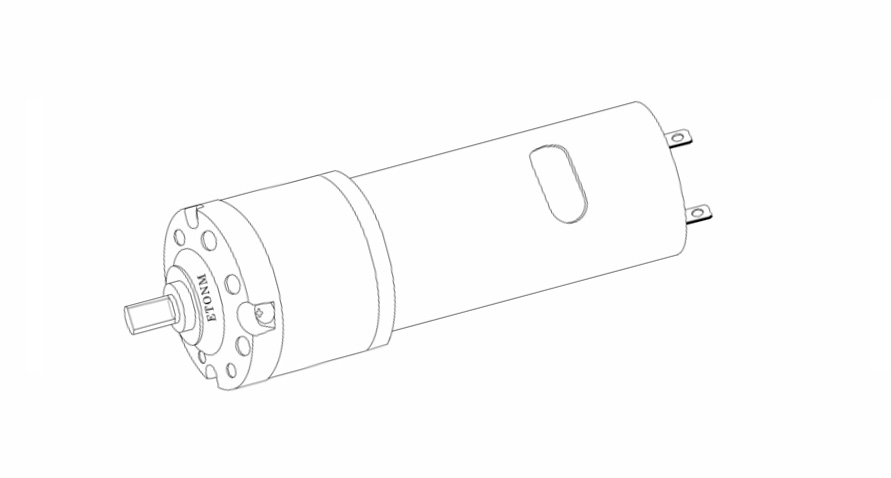

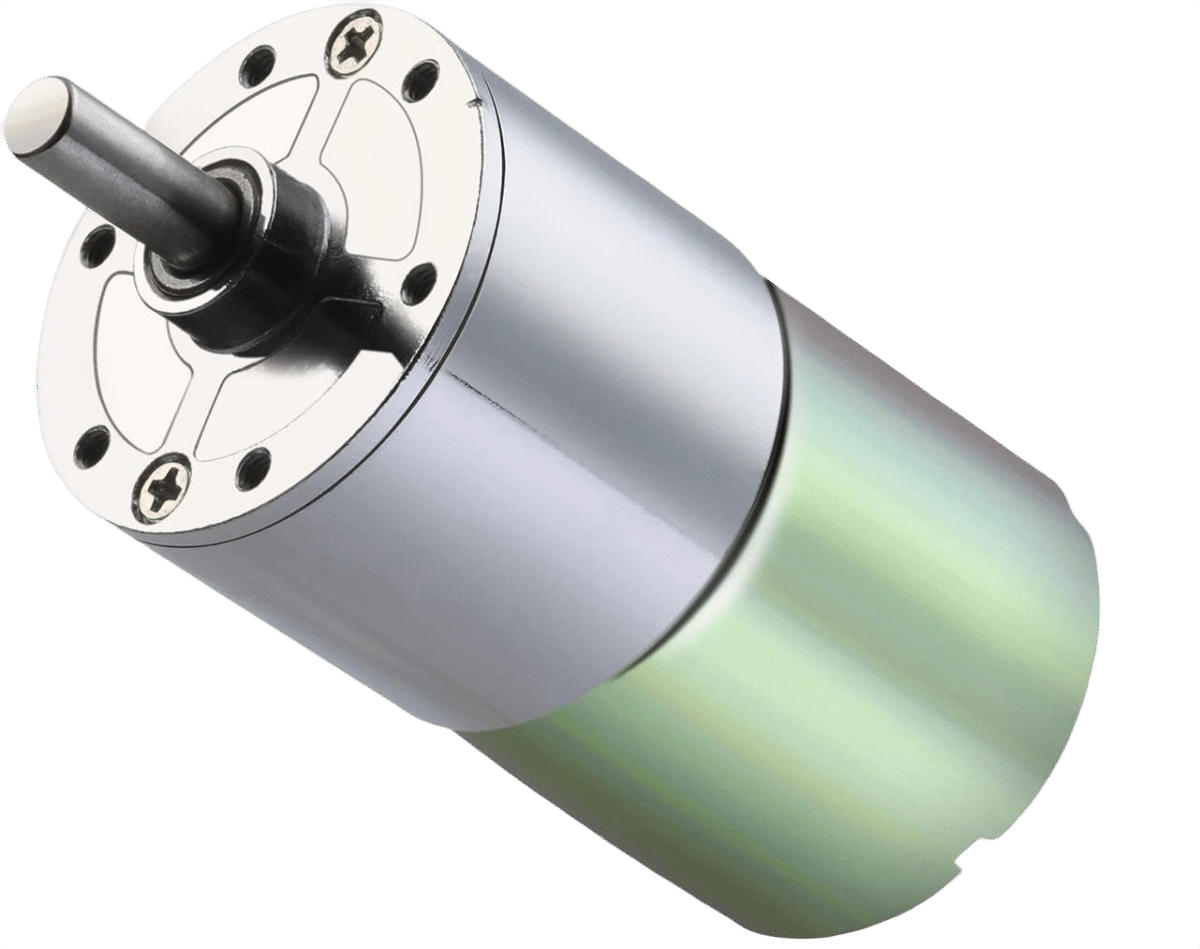

Planetary Gear Motors: Known for their compact design and high efficiency, these motors are ideal for applications requiring precise control and high torque.

Worm Gear Motors: With their ability to handle heavy loads and operate quietly, these motors are a favorite for lifts, conveyors, and automated systems.

Brushless Motors: Offering smooth operation and long lifespan, brushless motors are perfect for robotics and high-performance applications.

Real-World Success Stories

Many of our customers have used Etonm Motor’s 12V low speed high torque motors to create incredible projects. For example, one DIY enthusiast built a motorized camera slider for time-lapse photography using our planetary gear motor. The motor’s smooth, controlled movement allowed them to capture stunning, professional-quality footage.

Another customer used our worm gear motor to power a homemade lift for their workshop. The motor’s high torque and low speed made it easy to lift heavy tools and equipment safely and efficiently.

Take Your Projects to the Next Level

Ready to find the perfect motor for your next DIY project? Explore Etonm Motor’s range of 12V DC motor high torque low rpm options today. Whether you’re a seasoned engineer or a beginner, we have the tools and expertise to help you succeed.

Visit our website to learn more about our products, or contact us for personalized recommendations. Let’s bring your ideas to life together!

Conclusion – Unlock the Potential of 12V Low Speed High Torque Motors

In the world of DIY projects, having the right tools can make all the difference. A 12V low speed high torque motor is one of those tools—a compact, powerful, and versatile solution that can elevate your creations to new heights. From lift mechanisms and model cars to robotics and smart home devices, these motors offer the perfect balance of control, power, and efficiency.

Throughout this article, we’ve explored how gear reduction enhances torque, the wide range of applications for these motors, and practical tips for choosing the right one. Whether you’re a seasoned maker or just starting your DIY journey, a 12V DC motor high torque low rpm can be the key to unlocking your project’s full potential.

At Etonm Motor, we’re passionate about empowering innovators like you. Our range of 12 volt motor high torque low rpm options is designed to meet the diverse needs of DIY enthusiasts, engineers, and hobbyists. With customizable solutions, high-quality materials, and expert support, we’re here to help you bring your ideas to life.

Explore 12V DC Motors

Related Reading

- Tailored Power: High Torque Custom 12V Motors for Pros

- 12V High Torque DC Motors: Your Guide to Power and Precision

- High Torque Gear Motors: Unleashing 12V Power for Robotics

- DC Motor Speed Controller 12V Basics: From Brushed to BLDC

- Custom Control: Pairing 12V DC Motors with Speed and Encoder Accessories

- 12V DC Motor High Torque High RPM: Torque vs. Speed

- 12V DC Motor Speed Controllers: How They Work & Setup Tips

- What Is DC Motor Torque? A Simple Guide by Etonm Motor

- What is Electronic Speed Control (ESC) for Brushless DC Motors?

- Power Up Precision: High-Speed Brushless DC Motors for Screwdrivers

- How to Increase Torque in Brushless DC Motors: A Practical Guide

- BLDC Motor Speed Control: Methods, Tips & Applications

- 12V DC Motor High Torque Low RPM Performance

- Small But Mighty: Mastering Small High Torque 12V Motors