"Confused about 12V vs 24V DC motors? This guide compares their power, torque, and uses—from portable devices to industrial tasks. Learn how a 24v electric motor or 12v 24v dc motor fits your needs with Etonm Motor’s expert tips."

Table of Contents

Introduction

Choosing the right motor for your project can feel like picking the perfect tool from a crowded toolbox—especially regarding voltage. If you’ve ever wondered whether a 24v electric motor or a 12v one is the way to go, you’re not alone. These two options pop up everywhere, from DIY gadgets to heavy-duty machines, and knowing which fits your needs can make or break your design. So, how do you decide? Let’s dig in and sort it out together.

Voltage isn’t just a number—it’s the heartbeat of a motor’s performance. Whether you’re powering a portable device or a factory setup, 12V and 24V DC motors bring something unique. Here at Etonm Motor, we’ve spent years crafting custom solutions for everything from smart home systems to industrial robotics, so we’ve seen firsthand how the right voltage can spark success. Stick around as we break down the differences, uses, and tips to help you choose the perfect fit for your next big idea!

How Voltage Affects Motor Performance

Let’s get to the nuts and bolts: How does voltage actually shape what a motor can do? Whether it’s a 12V or a motor DC 24v, voltage is like the fuel in your car—it determines how much power you’ve got under the hood. In simple terms, higher voltage means more juice flowing through the system, which can boost performance in a few key ways: power, torque, and current. But it’s not just about going big—there’s a catch worth understanding.

Start with power. A 12v DC motor might deliver 10-20 watts, ideal for lighter tasks like running a small pump or fan. Bump it up to a motor DC 24v, and you could hit 40-50 watts or more, enough to tackle heavier loads without breaking a sweat. Torque follows suit—24V motors churn out more twisting force, making them a go-to for things that need muscle, like conveyor belts or automated gates. Current’s the kicker: at 24V, you can push the same power with less current than at 12V, cutting down on heat and wire strain. Pretty smart, right?

At Etonm Motor, we’ve learned this firsthand designing motors for all sorts of jobs. A 12V setup might hum along happily in a handheld tool, but a motor DC 24V shines when the workload ramps up. It’s all about matching the voltage to what you’re asking the motor to do—get that right, and you’re golden.

Typical Uses for 12V DC Motors

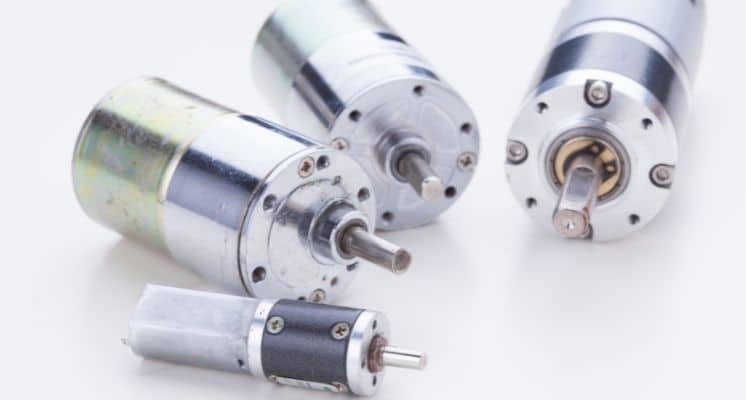

So, where does a 12v DC motor really shine? If you’re picturing something portable or small-scale, you’re on the right track. These motors are the go-to choice for projects that need reliable power without a ton of fuss. They’re like the trusty sidekick in your toolkit—always ready to step up for the little jobs that keep life moving.

One big win for 12v DC motors is in portable devices. Think car accessories like electric fans or windshield wipers—they run off a 12V battery and don’t need much space or juice. The same goes for DIY projects: a 12v DC motor can power a homemade robot or a model train with ease, especially since it pairs so well with a standard car battery or a simple power adapter. I’ve seen folks rig up solar-powered gadgets with these too, thanks to their low power draw—usually in the 10-20 watt range—which keeps things efficient and wallet-friendly.

At Etonm Motor, we’ve built plenty of 12v DC motors for stuff like smart home gear—think motorized blinds or a compact water pump. They’re lightweight, affordable, and easy to hook up, making them a favorite for tinkerers and pros alike. Sure, they won’t haul a factory load, but for small-scale magic, 12V is tough to beat.

Advantages of 24V DC Motors

When it’s time to step up your game, a 24v electric motor might just be the MVP you need. These motors are built for the heavy hitters—think industrial setups or projects that demand more oomph than a 12V can muster. If you’re wondering why 24V gets the nod in tougher spots, let’s unpack the perks that make it stand out.

First off, power and efficiency are where a 24v electric motor flexes its muscles. With double the voltage of a 12v DC motor, it can push 40-50 watts or more without blinking—perfect for high-load tasks like running a conveyor belt or lifting gear in a warehouse robot. That extra juice also means better torque, so it’s no surprise you’ll spot these in electric scooters or beefy automation systems. Plus, here’s a neat trick: at 24V, you can deliver the same power with less current than a 12V setup, which cuts down on heat and keeps things running cooler and longer.

And let’s talk trends—enter the 24 volt brushless motor. These bad boys ditch the brushes for higher efficiency and durability, making them a hot pick for modern industrial rigs or even advanced robotics. At Etonm Motor, we’ve seen 24v electric motors thrive in everything from vending machine dispensers to heavy-duty smart valves. They cost a bit more upfront, but for jobs that need stamina and strength, they’re worth every penny.

Key Considerations for Choosing Between 12V and 24V

Choosing between a 12v DC motor and a 24v electric motor isn’t just a coin toss—it’s about matching the motor to your mission. Whether you’re wiring up a 12v 24v DC motor for a DIY build or a pro-grade setup, a few key considerations can steer you straight. Let’s walk through what matters most so you’re not left scratching your head.

First, think about power compatibility. A 12v DC motor plays nice with car batteries or small adapters—super handy for portable stuff like camping gear or a kid’s robot. But if you’re running a motor DC 24v for something beefier, like a factory tool, you’ll need a heftier power source, maybe a 24V battery pack or a solid wall supply. Check what you’ve got on hand; swapping systems mid-project is a hassle nobody wants.

Cost’s another biggie. A 12v DC motor is usually lighter on the wallet upfront—great for tight budgets or one-off experiments. A 24v electric motor, though, might pinch more at first but pays off in efficiency for long-haul jobs. To make it clear, here’s a quick comparison:

| Feature | 12V DC Motor | 24V DC Motor |

|---|---|---|

| Power Output | 10-20 watts | 40-50 watts+ |

| Typical Use | Portable devices, DIY | Industrial, high-load |

| Cost | Lower upfront | Higher, but more durable |

| Power Source | Car battery, small adapter | 24V battery or wall power |

At Etonm Motor, we’ve got both in our lineup—12v DC motors for the nimble stuff and 24v electric motors for the heavy lifters. Not sure which way to lean? Hit us up at contact us—we’ll sort out the perfect 12v 24v dc motor for your gig!

Conclusion

And there you have it—the lowdown on 12V versus 24V DC motors! Whether you’re powering a portable gadget with a 12v DC motor or cranking up the juice with a 24v electric motor for a heavy-duty task, it’s all about picking the right voltage for the job. The 12V keeps things light and simple—perfect for DIY or on-the-go projects—while the 12v 24v DC motor debate lands on 24V when you need stamina and strength for industrial challenges. Pretty cool how versatile these little engines can be, right?

At Etonm Motor, we’re here to make that choice a breeze. From custom 12v DC motors for smart home tweaks to rugged 24v electric motors for your next big build, we’ve got the goods to spark your ideas. Curious about what fits your project? Swing by our DC Motor collection or shoot us a message—we’d love to help you get rolling!

Recommended 12v DC Motors by Etonm Motor

Recommended 24v DC Motors by Etonm Motor

Related Reading

- 3V and 5V DC Motors: A Beginner’s Guide

- 12v DC Planetary Gear Motor: Power & Precision by Etonm Motor

- 24v Planetary Gear Motor: Strength Meets Efficiency

- Gear Motor vs DC Motor vs Stepper Motor: Key Differences

- Helical Worm Gear Motor vs. Worm Gear Stepper Motor

- Spur Gear Motor vs. Worm Gear Motor: Which Is Best?

- Planetary Gear Motors vs. Spur Gear Motors: Which Wins?

- Comparison of Commutation Methods in Brushless DC Motors: Sensor vs. Sensorless

- Brushless DC Motors vs. Brushed DC Motors: Key Advantages

- Brushless DC Motor vs. Servo Motor: What’s the Difference?

- AC Motors vs DC Motors: Which is Best for Your Application?

- BLDC Motor vs Brushed Motor: Which is Better for Your Needs?

- 12V DC Motor High Torque Low RPM Performance

- Introduction of 12V DC Micro Motor Products

- Why Choose 24v Small DC Motors?

- 12V DC Motor with Encoder: Precision Guide for Beginners

- 12V Gear Motor Guide: Worm vs Planetary Gears

- 12 Volt 1 HP DC Motors: Powering Fans to Heavy Duty

- 12V DC Motor Guide: From Basics to Uses

- 12V DC Motor Speed Controllers: How They Work & Setup Tips

- 12V DC Air Pump Motors: Small Size, Big Pressure