" Struggling to pick the right brushed DC motor? This guide breaks down the key factors—like power, speed, and application—to help you select a motor that fits your needs perfectly. "

Table of Contents

Introduction

Picture this: you’ve got a brilliant idea for a smart home gadget, a robotic arm, or maybe a vending machine that dispenses snacks like a champ—only to realize the motor you picked can’t keep up. It’s frustrating, right? Choosing the right brushed DC motor isn’t just about grabbing something off the shelf; it’s about matching power, speed, and durability to your project so it runs smoothly without burning a hole in your wallet. Whether you’re a hobbyist tinkering in your garage or a designer finalizing a product spec, getting this step right can make or break your creation.

Let’s face it—motors can feel like a maze of specs and buzzwords if you’re not an electrical engineer. That’s why I’m here to break it down for you in plain English. In this guide, we’ll walk through the essentials of how to select a motor that fits your needs—think voltage, torque, size, and even how long it’ll last before you need to swap it out. By the end, you’ll have a clear roadmap to pick a brushed DC motor that powers your project like a pro, no guesswork required. Ready to dive in? Let’s get rolling!

What Is a Brushed DC Motor and Why Does It Matter?

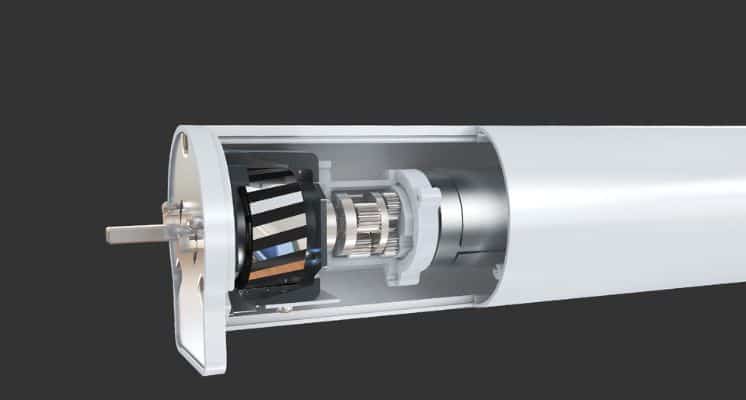

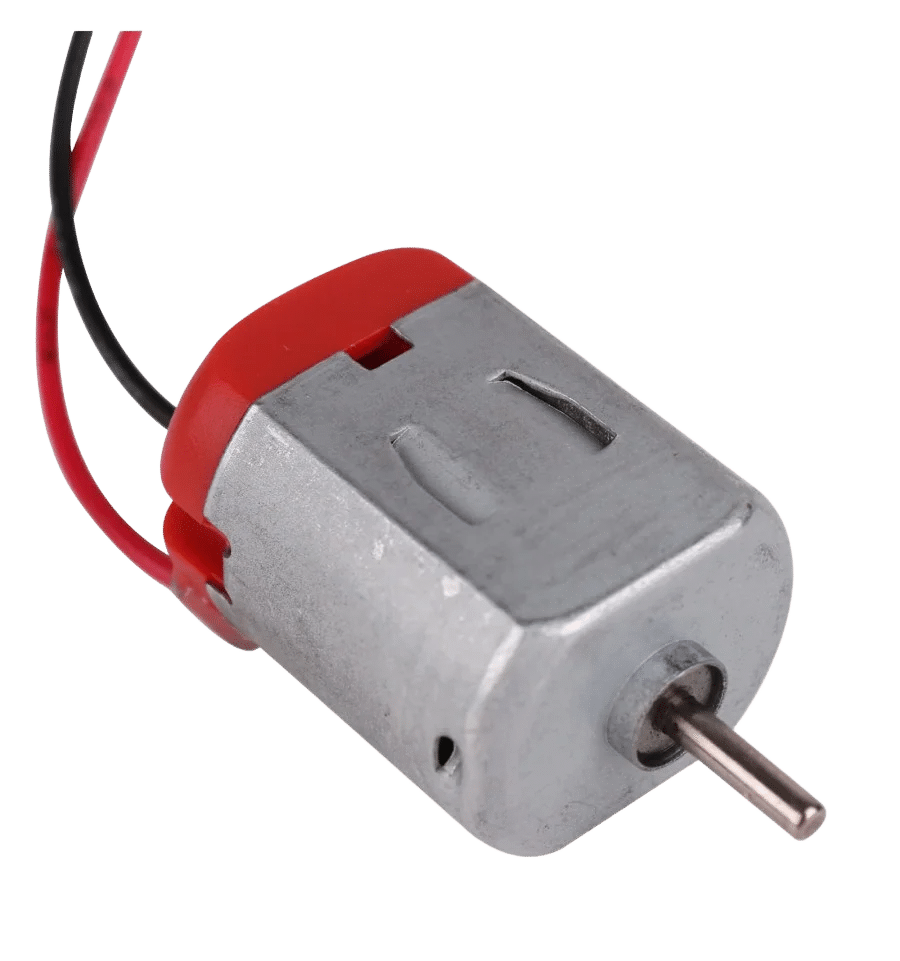

When you’re picking a motor, understanding what you’re working with is half the battle. A brushed DC motor is one of the oldest and most straightforward types of electric motors out there—it’s been around since the 19th century, and yet it’s still a go-to for everything from toy cars to industrial valves. At its core, it’s powered by direct current (DC) and uses brushes and a commutator to keep the rotor spinning. That simplicity is what makes it so popular: it’s affordable, easy to control, and doesn’t need fancy electronics to get going. But why should you care? Because knowing its strengths—and limits—can help you decide if it’s the right fit for your next big idea.

These motors shine in applications where you need reliable performance without breaking the bank. Think about a smart home device like an automated curtain opener or a sanitary dispenser that pumps out just the right amount of soap—chances are, a brushed DC motor is quietly doing the heavy lifting. They’re not perfect for everything, though; the brushes wear out over time, and they’re not as efficient as their brushless cousins. Still, for projects where cost and simplicity trump longevity, they’re tough to beat. Let’s dig a little deeper into how you can spot one and why that matters.

How Do You Identify a Brushed Motor?

So, how do you identify a brushed motor if you’ve got one in front of you? It’s not like they come with a neon sign flashing “brushed!”—but there are a few telltale signs. Physically, you might notice two wires (positive and negative) since they run on DC power, and if you crack one open (not that I’m suggesting you do), you’d see carbon brushes pressing against a segmented commutator on the rotor. Compare that to a brushless motor, which often has more wires and relies on electronic controllers instead of brushes. If you’re testing it, hook it up to a power source—brushed motors start spinning with just a basic DC supply, no extra gadgets required.

Identifying it isn’t just a nerdy party trick; it helps you figure out what you’re dealing with in terms of maintenance and performance. For instance, those brushes mean you’ll get sparks and some wear over time—typically lasting 1,000 to 3,000 hours depending on the load and quality. That’s fine for a vending machine that runs a few cycles a day, but maybe not for a high-speed drone. Knowing this upfront saves you from picking a motor that’ll fizzle out too soon—or one that’s overkill for your needs. Next up, we’ll look at the nitty-gritty of choosing the right one for your project.

Key Factors to Consider When Choosing a Brushed DC Motor

Picking the perfect brushed DC motor isn’t about flipping a coin—it’s about matching the motor’s specs to what your project demands. There’s no one-size-fits-all here; a motor that’s a champ in a robotic arm might flop in a smart home gadget. To make this less of a guessing game, let’s break down the big four factors you need to think about: voltage, speed, size, and durability. Nail these, and you’ll have a motor that hums along without leaving you scratching your head—or your budget in tatters.

Voltage and Power Requirements

First up, let’s talk voltage—because without the right juice, your motor’s going nowhere. Brushed DC motors come in a range of voltage options, like 6V, 12V, or 24V, and it’s your job to match that to your power source and project needs. A low-voltage motor (say, 6V) might be perfect for a battery-powered toy, keeping things lightweight and efficient. But if you’re running an electric valve in a water meter that needs more oomph, stepping up to 24V could save you from underpowered stutters. Check your setup—does it run on batteries or a wall adapter?—and pick a motor that won’t strain your system or demand a complete redesign.

Power ties right into this, too. Think about what your motor’s driving: a tiny gear in a sanitizer dispenser doesn’t need the same grunt as a conveyor belt in a vending machine. Look at the motor’s wattage rating (volts times amps) to get a sense of its muscle. How to select a motor starts here—get this wrong, and you’re either wasting energy or stalling out when it counts.

Speed and Torque Needs

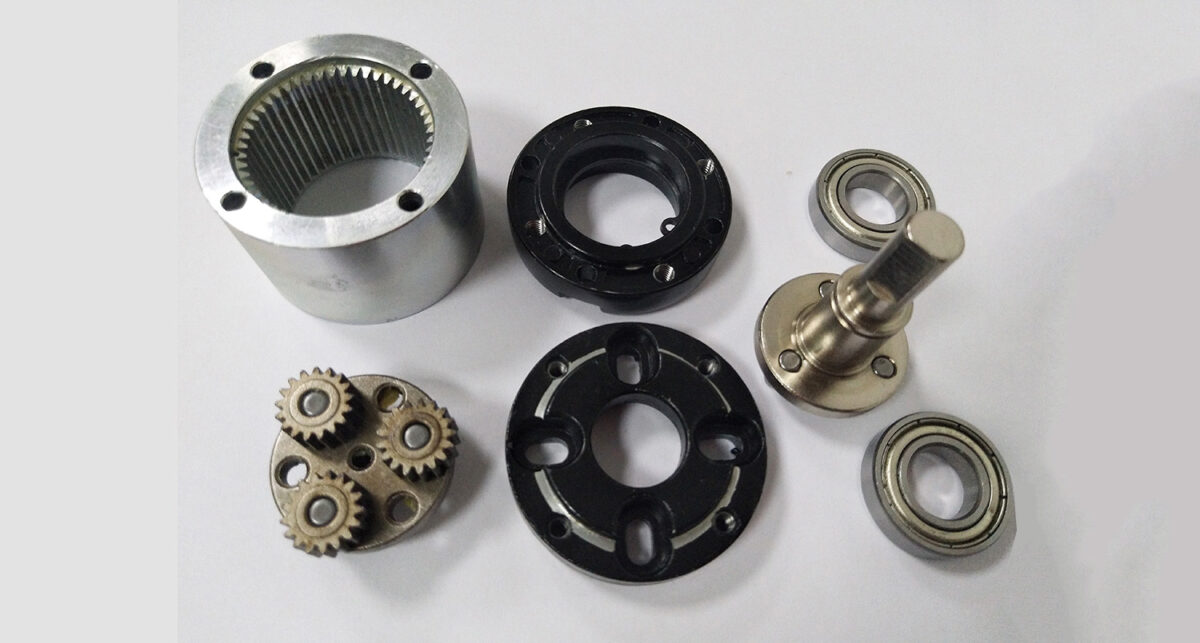

Next, let’s zoom into speed and torque—the dynamic duo of motor performance. Speed, measured in RPM (revolutions per minute), tells you how fast the motor spins unloaded, while torque is the twisting force it delivers to move your load. How do you choose the right DC motor? It depends on your gig. A high-RPM motor (think 3,000 RPM) might be great for a fan, but if you’re building a robotic gripper that needs to lift something heavy, you’ll want lower speed with higher torque—maybe 100 RPM with a beefy gearbox attached.

Here’s a real-world tip: don’t just chase raw numbers. Pairing a brushed DC motor with a gearbox (like planetary or worm gear) can tweak the speed-torque balance to fit your needs—like slowing down a zippy motor to crank up its pulling power for a curtain opener. Test your prototype with the actual load to see if it’s Goldilocks-level “just right.”

Size and Mounting Options

Size matters more than you might think—especially when space is tight. A chunky motor won’t squeeze into a sleek medical device, and a tiny one might not pack enough punch for an industrial tool. Measure your project’s footprint and check the motor’s dimensions—length, diameter, and weight. For example, flat gearbox motors are ace for slim designs like smart locks, while round brushed DC motors with a planetary gearbox might suit a beefier robot arm.

Mounting’s the unsung hero here. Does your motor need screw holes, a flange, or just a snug fit into a custom bracket? I’ve seen folks pick a killer motor only to realize it won’t bolt onto their frame without a hacksaw and some swearing. Flip through the spec sheet or chat with your supplier to avoid that headache—custom options can save the day.

Durability and Maintenance

Last but not least, let’s talk about how long your motor will last before it’s toast. Brushed DC motors are tough little workhorses, but those brushes wear down—typically lasting 1,000 to 3,000 hours under normal loads. That’s plenty for a security camera that pans occasionally, but if you’re running a high-duty cycle (like a medical pump humming 24/7), you might need to plan for replacements or step up to a beefier model. Heat, dust, and heavy loads can shave that lifespan, so factor in your environment too.

Maintenance is pretty low-key—keep it clean, avoid overloading, and you’re golden. Still, how to select a motor means knowing your uptime needs. If downtime’s a dealbreaker, look for motors with replaceable brushes or ask your supplier about lifespan data. A little foresight here keeps your project purring instead of sputtering.

Matching Your Motor to the Application

Choosing a brushed DC motor isn’t just about specs on a datasheet—it’s about picturing it in action, powering your project like it was born to do it. Different applications have their own quirks, and what works for a robot whirring across your living room might not cut it for a vending machine spitting out candy bars. The trick is knowing what your setup demands and finding a motor that fits like a glove. Let’s explore some common uses and see how to make that match happen.

Take robotics, for starters. A small brushed DC motor with a planetary gearbox might be your MVP here—think 12V, moderate speed, and enough torque to roll wheels or pivot a gripper. I’ve seen hobbyists rig up a 100 RPM motor to a little bot that hauls itself over carpet like a champ, no sweat. It’s all about balancing power and precision so your robot doesn’t end up spinning its wheels—literally. (Want more on this? Check out our guide to brushed DC motors for robotics for a deeper dive.)

Now, picture a smart home device—like an automated soap dispenser in your bathroom. You don’t need a monster motor here; a compact 6V brushed model with a worm gearbox does the trick, pumping out just enough soap without waking the neighbors. These motors are quiet, efficient, and small enough to tuck into tight spaces—perfect for keeping your countertop sleek. The key is low power and steady delivery, not raw horsepower.

Then there’s stuff like vending machines or electric valves in water meters, where reliability trumps everything. A 24V brushed DC motor with solid torque can handle the heavier loads—like dispensing snacks or opening a valve under pressure. I talked to a guy once who swapped out a flaky motor in his vending machine for one with a beefier commutator, and boom—zero jams for months. Match the motor to the duty cycle: if it’s running nonstop, prioritize durability over dirt-cheap pricing.

Medical care’s another spot where these motors pop up—like in portable pumps or adjustable beds. Here, you’re looking at smooth operation and a decent lifespan (think 2,000+ hours) since nobody wants a pump conking out mid-shift. A real example? A 12V brushed motor with a flat gearbox powering a sanitizer sprayer—quiet, reliable, and just the right size for a handheld unit. How do you choose the right DC motor for this? Focus on consistency and check if the supplier can tweak it for your exact specs.

The takeaway? Think about your project’s “day job”—is it lifting, spinning, pushing, or just sitting pretty? Map that to voltage, torque, and size, and you’ll land on a brushed DC motor that’s more than just “good enough.” It’s about solving the puzzle of what your application needs, not just picking the shiniest toy in the box.

Where to Find Quality Brushed DC Motors

So, you’ve got a handle on what makes a brushed DC motor tick—voltage, torque, size, the works. Now comes the fun part: actually finding one that doesn’t let you down halfway through your project. It’s not like you can stroll into a hardware store and pluck the perfect motor off the shelf (well, not usually). Whether you’re building a one-off prototype or scaling up for production, sourcing a reliable motor means knowing where to look and what to check for.

Start with the basics: specs and reputation. Dig into supplier websites—good ones list detailed datasheets with voltage ranges, RPM, torque curves, and lifespan estimates, not just some vague “it spins!” promise. Places like DigiKey or Mouser are solid for off-the-shelf options if you’re in a pinch, but for something tailored—like a 12V motor with a worm gearbox for a smart lock—specialized manufacturers are your best bet. I’ve found that companies with a track record in motors (bonus points if they’ve been around a while) tend to deliver fewer duds. Check reviews or ask around in forums if you’re unsure—nobody wants a motor that buzzes out after a week.

Quality isn’t just about the motor itself; it’s about support too. A decent supplier won’t ghost you when you’ve got questions—like “Can this handle 50% duty cycles?” or “What’s the noise level on this thing?” Some even offer customization, tweaking gear ratios or brush materials to match your exact needs. I once worked with a guy who got a custom brushed DC motor for a vending machine retrofit—tweaked torque, quieter operation, the whole nine yards—and it saved him from scrapping his design. If precision matters, ask about that upfront.

Want a pro tip? Cross-check specs with real-world advice. The folks at IEEE have some great resources on motor selection—like this guide on DC motor basics that’s worth a skim if you’re nerding out on details. Pair that with supplier data, and you’re less likely to end up with a lemon. Don’t just chase the cheapest option either— a $5 motor might save you now but cost you triple in replacements later.

In short, finding a quality brushed DC motor is about doing your homework. Stick to suppliers who know their stuff, aren’t afraid to chat specs, and can deliver something that fits your project like it was made for it—because, sometimes, it can be. Your robot, dispenser, or valve deserves better than a coin toss, right?

Conclusion

Picking the right brushed DC motor doesn’t have to feel like rocket science—or a roll of the dice. It boils down to a few key moves: match the voltage and power to your setup, dial in the speed and torque for the job, size it right, and make sure it’ll last as long as you need it to. Whether you’re powering a robot, a smart home gadget, or a vending machine, those basics will steer you toward a motor that gets the job done without drama. Think of it like picking a teammate—you want one that’s reliable, not one that bails mid-game.

Related Reading

- Exploring Types of Micro Motors and Their Future Trends

- Brushless DC Motors vs. Brushed DC Motors: Key Advantages

- What Is DC Motor Torque? A Simple Guide by Etonm Motor

- AC Motors vs DC Motors: Which is Best for Your Application?

- BLDC Motor vs Brushed Motor: Which is Better for Your Needs?

- The Ultimate Guide to Brushless DC Motors: Types, Applications, and Benefits

- Smart Lock Motor Solutions for Modern Security

- Exploring Robot Motors: A Comprehensive Guide