Confused about gear motors, DC motors, and stepper motors? Learn their key differences, applications, and which one suits your project best with Etonm Motor’s expert insights.

Table of Contents

Introduction

Choosing the right motor for your project can feel like picking the perfect tool from a crowded toolbox—get it wrong, and you’re stuck with inefficiency, higher costs, or a device that just won’t perform. Whether you’re designing a smart home gadget, a robotic arm, or an electric valve, the decision often boils down to three big players: gear motors, DC motors, and stepper motors. Each has its strengths, quirks, and ideal use cases, but how do you know which one’s the best fit? That’s where understanding the differences in Gear Motor vs DC Motor vs Stepper Motor comes in handy—and trust me, it’s not as complicated as it sounds!

At Etonm Motor, we’ve spent years crafting custom solutions like planetary gear motors, micro DC motors, and more for industries ranging from medical care to vending machines. We’ve seen firsthand how the right motor can make or break a design. In this guide, we’ll break down what sets these motors apart, explore their real-world applications, and help you figure out which one suits your next big idea. So, let’s dive in—by the end, you’ll be ready to pick a motor with confidence. Which one’s right for your project? Stick around to find out!

What Is a Gear Motor?

If you’ve ever wondered how heavy machinery or even your smart home devices manage to move with such controlled power, chances are a gear motor is behind it. At its core, a gear motor is a clever combo: a standard motor—usually DC or AC—paired with a gear reduction system. Think of it as a translator that takes the motor’s high-speed energy and turns it into slower, more forceful motion. That’s why gear motors are the go-to choice when you need high torque at low speeds, whether it’s lifting a robotic arm or powering a vending machine’s dispenser.

How Gear Motors Work

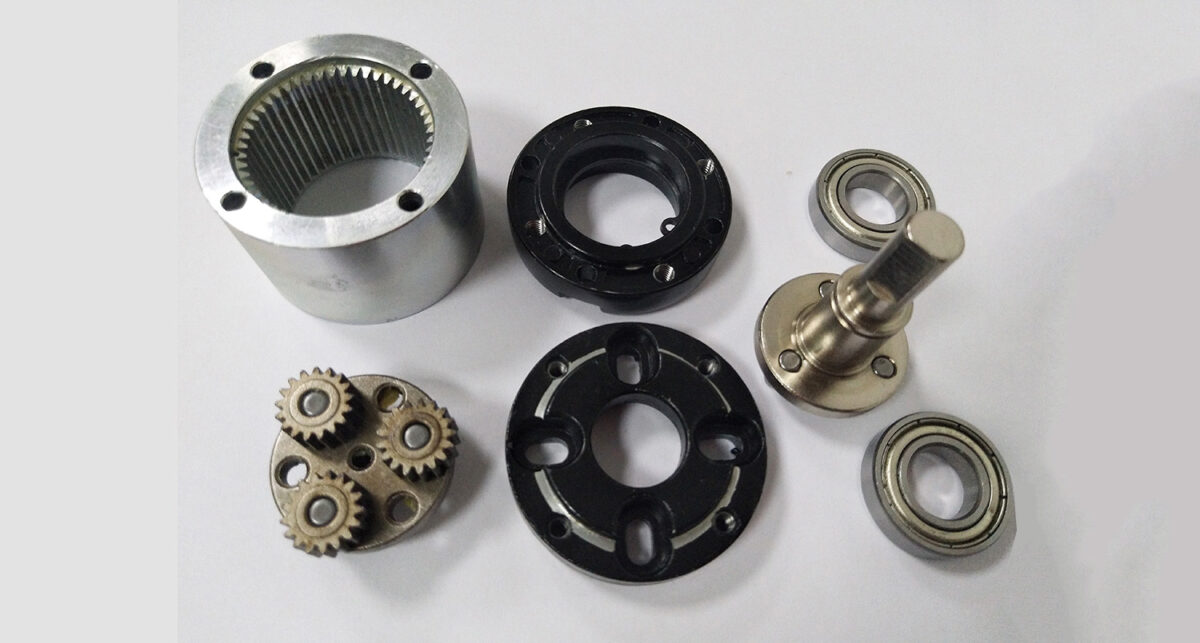

So, what’s the magic trick? It’s all in the gears. The motor spins fast—sometimes too fast for practical use—so the gearbox steps in to slow things down. By using a series of gears (think planetary or worm designs), it reduces the rotational speed while boosting torque. Picture a cyclist switching to a lower gear to climb a hill: less speed, more power. At Etonm Motor, we specialize in types of gear motors like planetary gear motors for precision or worm gear motors for durability—each tailored to handle specific challenges. The result? A compact powerhouse ready to tackle tough jobs without breaking a sweat.

Gear Motor Applications

Where do these unsung heroes shine? Gear motor applications are everywhere. In robotics, they drive joints that need steady, forceful movement. In smart home tech, they power automated blinds or locks with quiet efficiency. Ever used a sanitary dispenser that smoothly pumps out soap? That’s likely a gear motor at work. We’ve seen our clients at Etonm Motor use them in everything from electric valves for water meters to medical devices that demand reliability. For example, a customer once told us our flat gearbox motor kept their vending machine running flawlessly for years—proof these motors are built to last.

Gear motors aren’t just about brute strength, though. Their gearbox motor benefits include a compact design that saves space and versatility that fits both small gadgets and industrial setups. Sure, they might lose a bit of efficiency to gear friction, and the added complexity can bump up the cost, but when you need torque over speed, nothing beats them. Curious how they stack up against DC or stepper motors? Let’s keep going!

Understanding DC Motors

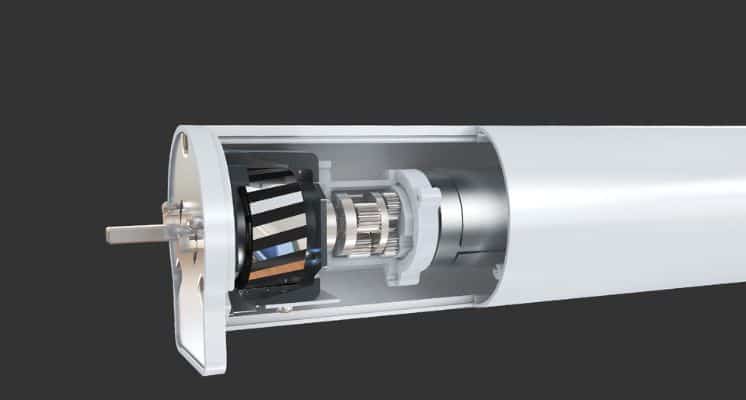

If gear motors are the heavy lifters, DC motors are the versatile all-rounders of the motor world. You’ve probably encountered them more than you realize—think of the whirring fan in your room or the drill in your toolbox. A DC motor takes direct current (DC) electricity and turns it into mechanical motion through a beautifully simple dance between a magnetic field and current-carrying coils. At Etonm Motor, we’ve been perfecting these workhorses for years, from micro DC motors for tiny gadgets to brushless versions for longer-lasting power. Let’s unpack what makes them tick and why they’re so popular.

DC Motor Basics

At their heart, DC motors are about simplicity. Picture this: a rotor (the spinning part) sits inside a stator (the stationary magnets), and a commutator flips the current to keep things moving. Add some brushes—or skip them in brushless designs—and you’ve got rotation. What’s cool about DC motors is how easy they are to control: tweak the voltage, and the speed adjusts like a dimmer switch. Etonm’s micro DC motors, for instance, are a favorite in compact applications like smart locks because they pack solid performance into a small package. Brushed or brushless, they’re built for straightforward, reliable action.

DC Motor Advantages

Why do DC motors keep showing up everywhere? For starters, they’re champs at DC motor advantages like easy speed control. Want your robot to zip along or slow down? Just dial the voltage up or down—it’s that simple. They’re also efficient for small-scale jobs, converting electricity to motion without much fuss. Ever wonder why your kid’s toy car runs so smoothly? That’s a DC motor keeping costs low and maintenance minimal—at least until the brushes wear out. In fact, stats from the motor industry suggest DC motors power over 70% of small appliances (source: IEEE), and it’s no surprise—they’re affordable, adaptable, and get the job done.

That said, they’re not perfect. Brushes can wear down, calling for occasional upkeep, and their torque isn’t as beefy as a gear motor’s. Still, for applications like electric valves or consumer electronics, their simplicity shines. Curious how they compare in a DC motor vs stepper motor comparison? We’ll get there soon—just hang tight!

Stepper Motors Explained

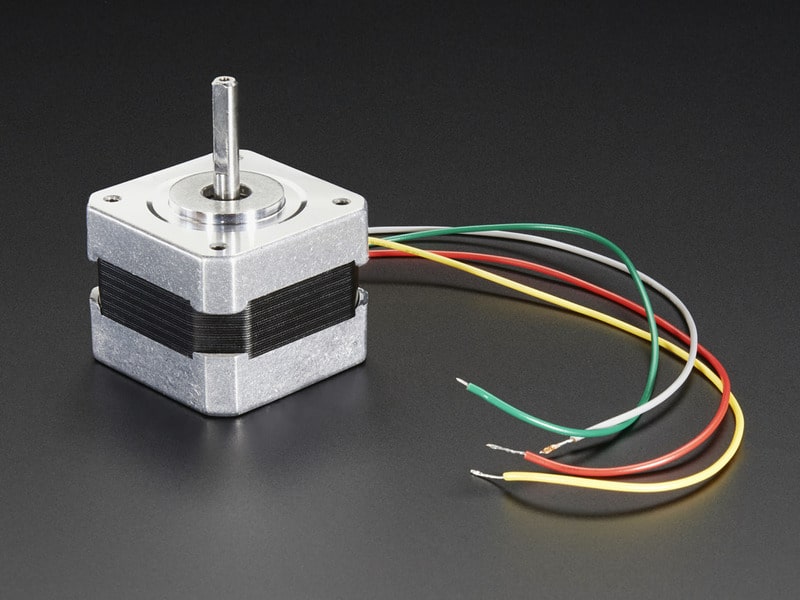

Imagine a motor that moves like a dancer hitting precise beats instead of spinning nonstop—that’s a stepper motor for you. Unlike DC motors that whirl continuously or gear motors that muscle through heavy loads, stepper motors take things step by step, literally. They’re the precision artists of the motor family, turning electrical pulses into exact, incremental movements. At Etonm Motor, we’ve seen these motors steal the show in applications where accuracy is everything, from 3D printers to robotic arms. Let’s dig into what makes them special and where they truly shine.

How Stepper Motors Operate

Here’s the gist: a stepper motor divides a full rotation into tiny, fixed steps—think 1.8 degrees per step for a standard model, or 200 steps per revolution. Each pulse from a controller tells it to move one step, no guesswork needed. That’s why they’re champs at stepper motor precision. Unlike DC motors, they don’t need constant feedback to know their position—just count the steps, and you’re golden. No wonder they’re a favorite in open-loop systems, where simplicity meets accuracy. Etonm’s stepper designs bring this precision to life, whether it’s for a camera gimbal or a medical pump that can’t afford to miss a beat.

Stepper Motor Precision and Uses

Precision is the name of the game here, and stepper motors deliver it in spades. Need to position a CNC machine’s cutting head exactly 2.5 millimeters to the left? A stepper motor nails it without breaking a sweat. They also pack high torque at low speeds, making them perfect for holding a position steady—say, keeping a robotic arm locked in place. That’s why they’re everywhere in choosing the right motor for robotics, as well as 3D printers, automated dispensers, and even high-end security systems. Fun fact: a client once told us our stepper motor made their prototype printer so accurate, they cut production errors by half!

Now, they’re not flawless. Stepper motors can get noisy with their step-by-step rhythm, and they’re not built for high-speed sprints—leave that to DC motors. But when control and accuracy trump everything else, they’re tough to beat. Ready to see how they stack up in a DC motor vs stepper motor comparison? Let’s roll on!

Gear Motor vs DC Motor vs Stepper Motor: A Side-by-Side Comparison

By now, you’ve got a solid grip on gear motors, DC motors, and stepper motors individually—but how do they stack up when you put them head-to-head? Choosing between them isn’t just about picking a favorite; it’s about matching the right tool to the job. Whether you’re tweaking a smart home device or building a robot from scratch, understanding the differences in Gear Motor vs DC Motor vs Stepper Motor can save you time, money, and a whole lot of frustration. Let’s break it down across three key areas: performance, cost, and use cases, with a little Etonm Motor know-how sprinkled in.

Performance and Efficiency

First up, let’s talk performance. Gear motors are the torque kings—thanks to their gearbox magic, they deliver high torque at low speeds, perfect for heavy lifting. Think of them as the slow-but-steady type; they’re not breaking speed records, but they’ll power through tough tasks like conveyor belts or robotic joints. Efficiency takes a slight hit from gear friction, though—something to keep in mind.

DC motors, on the other hand, are the smooth operators. They offer constant torque across a range of speeds, and you can tweak their pace with a simple voltage adjustment. In small-scale setups like fans or toys, they’re impressively efficient—often hitting 80% or higher, per motor industry data (source: IEEE). But crank up the load, and their torque can’t compete with a geared setup.

Then there’s the stepper motor, the precision maestro. It shines with high torque at low speeds too, but its step-by-step motion makes it less efficient at higher speeds—sometimes dipping below 50% when pushed hard. It’s a trade-off for that pinpoint control. In a DC motor vs stepper motor comparison, DC wins on efficiency, while steppers dominate precision.

Cost and Complexity

Next, let’s talk dollars and sense. Gear motors tend to cost more upfront because of that gearbox—they’re a bit like buying a car with a fancy transmission. The added complexity means more parts to maintain, but at Etonm Motor, we’ve seen our gearbox motor benefits pay off long-term; a well-made gear motor can outlast simpler options in demanding applications.

DC motors are the budget-friendly pick. Their straightforward design—especially brushed versions—keeps costs low and repairs easy, though brush wear means you’ll swap parts eventually. Brushless DC motors (like some of Etonm’s micro DC motors) bump up the price but cut maintenance hassles. For small projects, they’re hard to beat on value.

Stepper motors sit in the middle. They’re pricier than basic DC motors due to their control systems, but they don’t need gearboxes, which evens things out a bit. Setup is simpler too—no feedback loops required in open-loop designs. Still, if you’re not using their precision, you might be overpaying for features you don’t need.

Best Use Cases

So, where do they shine? Gear motors are your heavy-duty heroes—think industrial machinery, vending machines, or gear motor applications like sanitary dispensers where torque rules. DC motors thrive in simpler, speed-focused tasks: fans, pumps, or electric tools that need flexibility without breaking the bank. Stepper motors? They’re the go-to for choosing the right motor for robotics—think CNC machines, 3D printers, or anything requiring exact positioning.

Here’s a quick snapshot:

- Gear Motor: High torque, low speed—e.g., Etonm’s planetary gear motor in a medical lift.

- DC Motor: Variable speed, moderate torque—e.g., a micro DC motor in a smart lock.

- Stepper Motor: Precision, holding power—e.g., a stepper in a camera gimbal.

Still torn? The next section’s got your back with a decision guide!

How to Choose the Right Motor for Your Project

So, you’ve got gear motors, DC motors, and stepper motors on the table—now what? Picking the right one isn’t about guessing or flipping a coin; it’s about matching your project’s needs to what each motor brings to the party. Whether you’re tinkering with a DIY robot or designing a smart home gadget, a little clarity can go a long way. Let’s walk through a simple, three-step guide to help you nail the choice, with some insider tips from our team at Etonm Motor to keep you on track. Ready to make sense of Gear Motor vs DC Motor vs Stepper Motor? Here’s how.

Step 1: Assess Your Torque Needs

First things first: how much muscle does your project need? If you’re moving heavy loads—like a conveyor belt or an industrial lift—a gear motor’s high torque at low speeds is your best bet. Etonm’s planetary gear motors, for instance, have powered medical lifts that hoist patients with steady strength. Need moderate torque with some flexibility? A DC motor might do the trick, especially for lighter tasks like powering a fan. For precision-driven torque—say, holding a robotic arm steady—stepper motors shine. Ask yourself: “Is brute force or controlled power my priority?”

Step 2: Define Precision and Speed Requirements

Next up, think about control. If pinpoint accuracy is non-negotiable—like in choosing the right motor for robotics or a 3D printer—stepper motors are your MVPs thanks to their step-by-step precision. DC motors, though, are speed champs; tweak the voltage, and they’ll zip along for tasks like pumps or drills where smooth motion matters more than exact stops. Gear motors? They’re less about speed and more about steady power—great for fixed-pace jobs but not for rapid adjustments. So, decide: “Do I need precision, speed, or a slow-and-strong combo?”

Step 3: Balance Budget and Longevity

Finally, let’s talk practicalities. DC motors are the wallet-friendly option—simple, affordable, and perfect for quick projects, though brushes might need replacing down the line. Gear motors cost more upfront due to their gearbox complexity, but their durability (think gearbox motor benefits) can save you in high-wear scenarios—our clients swear by them for vending machines that run 24/7. Stepper motors land in the middle; they’re an investment in precision but skip the gearbox cost. Here’s the kicker: a cheap motor that fails early isn’t a bargain. What’s your budget, and how long do you need it to last?

Bonus Tip: Get Expert Input

Still stumped? That’s where we come in. At Etonm Motor, we’ve helped folks tweak everything from sanitary dispensers to electric valves with custom solutions—gear motors, DC motors, you name it. Drop us a line, and we’ll sort out the nitty-gritty so your project hums along perfectly. After all, the right motor isn’t just a part—it’s the heart of your design.

Conclusion

And there you have it—a rundown of Gear Motor vs DC Motor vs Stepper Motor that cuts through the noise. Gear motors bring the torque for heavy-duty tasks, DC motors keep things simple and speedy, and stepper motors nail precision like nobody’s business. Whether you’re powering a robotic arm, a smart lock, or a vending machine, each has its sweet spot. The trick? Match your project’s needs—torque, speed, or accuracy—to the motor that delivers. No one-size-fits-all here, but that’s what makes the choice so exciting!

At Etonm Motor, we’ve seen these motors in action across industries, from gear motor applications in medical devices to choosing the right motor for robotics. Want to dig deeper? Check out our full range of planetary gear motors, micro DC motors, and more on our site—there’s a solution for every challenge. Still not sure which one’s your winner? Reach out to us! We’re here to help you pick the perfect motor and get your project humming. After all, the right choice isn’t just smart—it’s the spark that brings your ideas to life.

Related Reading

- How to Maintain Gear Motors

- Why Choose 24v Small DC Motors?

- Comprehensive Guide to Low-Noise Gear Motors: Features, Types, and Applications

- How to Choose the Right Curtain Motor: Key Factors and Expert Tips

- BLDC Motor vs Brushed Motor: Which is Better for Your Needs?

- AC Motors vs DC Motors: Which is Best for Your Application?

- Brushless DC Motor vs. Servo Motor: What’s the Difference?

- Outrunner vs. Inrunner: Which Brushless DC Motor Fits Your Needs?

- Brushless DC Motors vs. Brushed DC Motors: Key Advantages

- Planetary Gear Motors vs. Spur Gear Motors: Which Wins?

- Spur Gear Motor vs. Worm Gear Motor: Which Is Best?

- Helical Worm Gear Motor vs. Worm Gear Stepper Motor