Struggling with planetary gear motor starting issues? You’re not alone. These compact, high-torque motors are fantastic for robotics, smart homes, and vending machines, but startup hiccups can throw a wrench in your plans. From low voltage to excessive loads, we’ll break down the common culprits and share practical fixes—like verifying power supply or tweaking lubrication—that keep your motor humming. With insights from Etonm Motor, a trusted manufacturer, learn how to troubleshoot and prevent these problems for good.

Table of Contents

Introduction

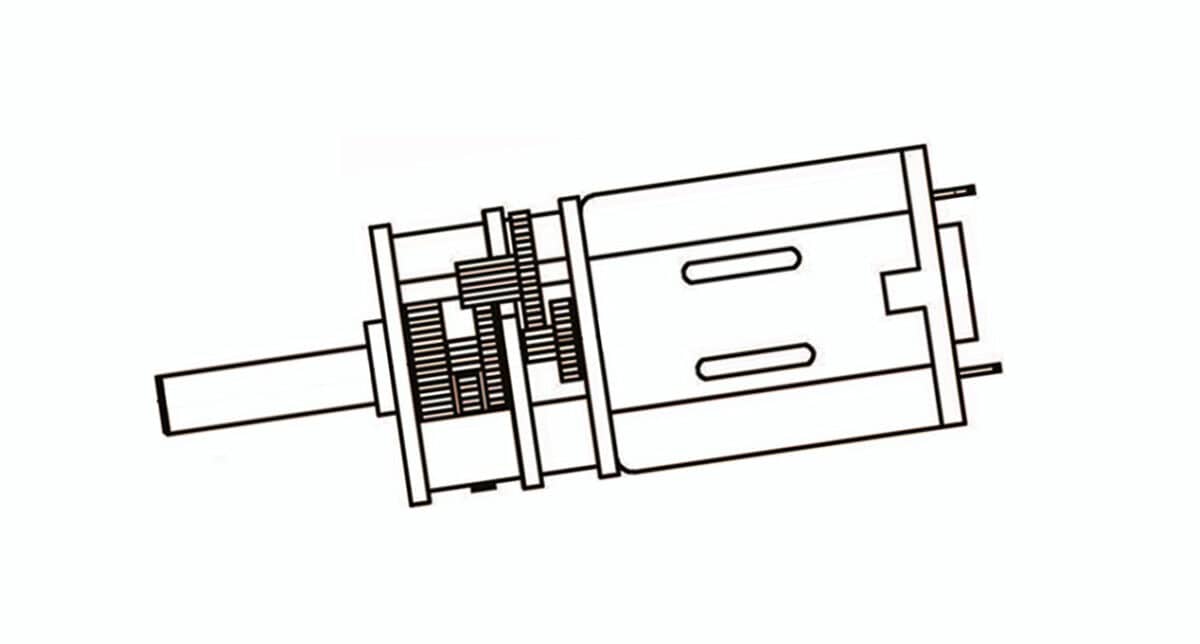

Picture this: you’ve got a planetary gear motor powering your latest robotics project or keeping a smart home gadget humming along, but when you flip the switch—nothing. Or maybe it groans like it’s begging for a coffee break. If you’ve ever faced planetary gear motor starting issues, you know how frustrating it can be. These motors are champs at delivering high torque in a compact package, making them go-tos for everything from vending machines to medical devices. But when they refuse to kick into gear, it’s not just a minor hiccup—it can stall your entire operation.

Here’s the good news: those startup struggles don’t have to be a mystery. Whether it’s a pesky voltage dip, an overloaded gearbox, or a lubrication slip-up, there’s a fix for that. In this guide, we’ll unpack the why behind these glitches and hand you practical solutions to get things spinning smoothly again. Drawing from years of expertise at Etonm Motor, a trusted name in custom motor manufacturing, we’re here to help you troubleshoot like a pro and keep those motors purring. Ready to dive in and solve the puzzle? Let’s get started.

Why Planetary Gear Motors Struggle to Start

When your planetary gear motor won’t budge, it’s tempting to blame bad luck—or maybe give it a motivational pep talk. But the real culprits behind planetary gear motor starting issues are usually more practical (and fixable) than that. These motors are engineering marvels, packing serious torque into a tiny footprint, but that complexity means a few things can go sideways. Let’s break it down into the big three: electrical gremlins, mechanical hiccups, and those sneaky environmental or design factors. Knowing what’s tripping you up is half the battle—here’s the rundown.

Electrical Culprits Behind Startup Woes

Ever hit the start button and gotten a feeble hum instead of action? Electrical problems are often the sneaky saboteurs. Planetary gear motor low voltage issues top the list—think of it like trying to run a marathon on an empty stomach. If your power supply dips below the motor’s rated voltage (say, less than 90% of what’s needed), it just can’t muster the oomph to overcome inertia. Insufficient current is another buzzkill; even with the right voltage, skimpy wiring or a weak breaker can starve the motor of torque. And don’t overlook faulty components—shorted windings or loose connections can turn your motor into a paperweight faster than you can say “multimeter.”

Mechanical Roadblocks

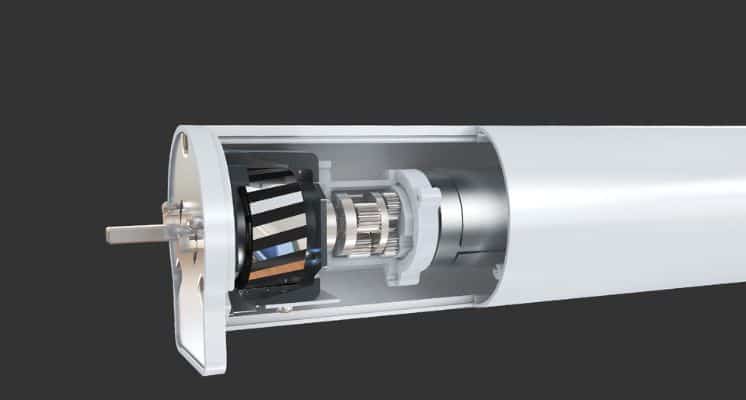

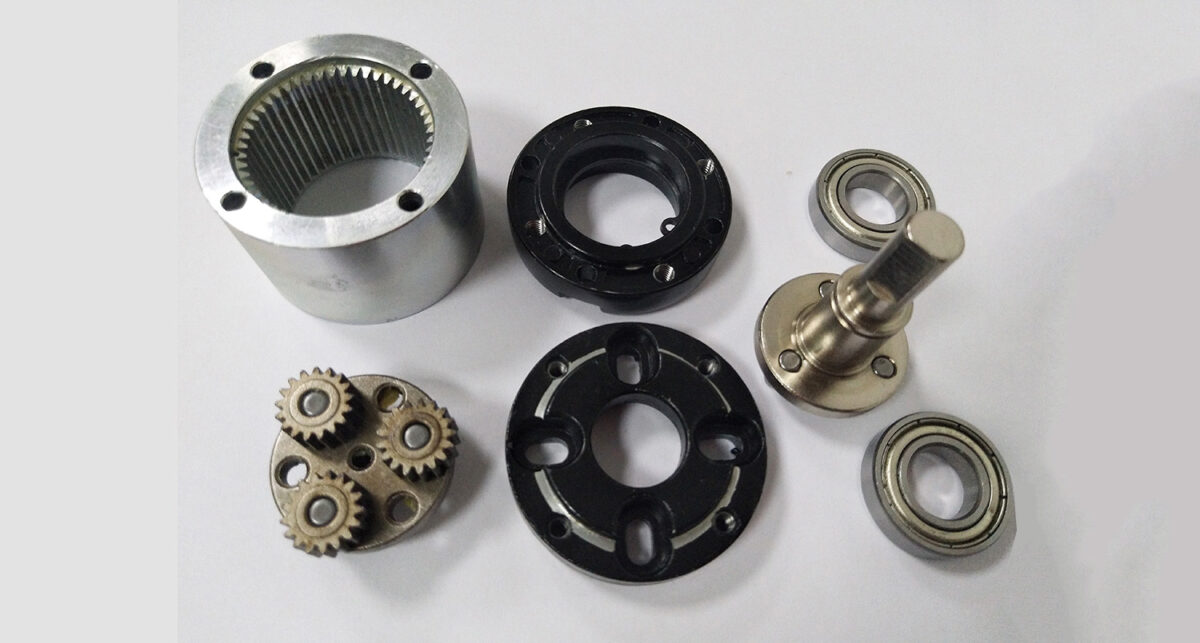

Sometimes the issue isn’t the juice—it’s the gears themselves. Mechanical problems can feel like pushing a boulder uphill. Excessive load is a classic: if your motor’s lugging more weight than it’s built for (think an overloaded conveyor belt), it’ll stall before it even starts. Worn or misaligned gears and bearings are just as bad, grinding away efficiency and spiking resistance. Then there’s lubrication—or the lack of it. Without the right grease, friction turns your gearbox into a sticky mess, making startup a slog. A quick peek inside might reveal more than you bargained for, but it’s worth it for those planetary gear motor troubleshooting tips that save the day.

Environmental and Design Factors

Mother Nature and human error can gang up on your motor, too. Extreme temperatures are brutal—scorching heat can fry windings, while frigid cold thickens lubricant until it’s more glue than glide. Dust or moisture sneaking in? That’s a recipe for jammed gears or shorted circuits. On the design side, an undersized motor—say, one too puny for your robotics rig—won’t muster the startup torque, no matter how hard it tries. Misaligned shafts from a sloppy install can also throw a wrench in things, literally stressing the motor out. It’s like building a house on a shaky foundation—small oversights lead to big headaches.

So, there you have it: the usual suspects behind those stubborn startups. Whether it’s a power hiccup, a gear grind, or a design whoops, pinpointing the cause is your first step to a fix. Up next, we’ll roll up our sleeves and tackle solutions that’ll have your motor spinning like it’s fresh off the line at Etonm Motor.

Practical Solutions to Get Your Motor Running

So, your planetary gear motor’s throwing a tantrum at startup—now what? Don’t worry, fixing planetary gear motor starting issues doesn’t require a PhD or a magic wand. Whether it’s an electrical glitch, a mechanical snag, or a design quirk, we’ve got you covered with straightforward solutions that actually work. Let’s roll up our sleeves and dive into the fixes, step-by-step, so you can get that motor humming again. With a little know-how from Etonm Motor, you’ll be back in business in no time.

Fixing Electrical Problems

If your motor’s acting like it’s on a power diet, start with the juice. First, grab a multimeter and check the voltage—anything below 90% of the motor’s rating (say, 10.8V on a 12V system) is a red flag. Boost the supply if needed—swap out a weak battery or upgrade your power source. Next, eyeball the current. Thin wires or a skimpy breaker can choke the flow, so replace them with beefier options that match the motor’s specs. Got a hunch about faulty windings? Test for continuity; if they’re toast, a rewind or replacement’s your ticket. Pro tip: tight connections are your friend—loose ones are a startup killer.

Tackling Mechanical Issues

When the gears are the grump, it’s time for some mechanical TLC. Overloaded? Lighten the load—split it across two motors or rethink your setup. A quick load test (e.g., does it stall under weight?) can confirm. If gears or bearings look worn—think grinding noises or wobbly shafts—pop the gearbox open and swap out the culprits. Lubrication’s your next stop. Ditch the guesswork and follow a planetary gear motor lubrication guide—use the manufacturer’s recommended grease, not whatever’s lying around. Clean out gunk while you’re at it; a smooth gearbox is a happy gearbox. One fix I swear by? A dab of lube can cut friction by 20% and save you a headache.

Optimizing Design and Environment

Sometimes the fix isn’t inside the motor—it’s around it. If temps are frying or freezing your setup, slap on a cooling fan for heat (keep it under 60°C) or a heating pad for cold (above 0°C works wonders). Dust or moisture creeping in? Wipe down the motor and consider a sealed enclosure—IP65 ratings are gold for harsh spots. On the design front, double-check alignment with a laser tool; even a 1mm skew can jam things up. And if the motor’s undersized for your robotics rig or smart home gadget, upgrade to one with more grunt—Etonm Motor can spec the perfect fit. Small tweaks here go a long way.

These aren’t just Band-Aids—they’re battle-tested planetary gear motor troubleshooting tips to keep downtime at bay. Next up, we’ll talk prevention, so you’re not stuck in this loop again. Ready to make your motor a champ? Let’s keep the momentum going.

Preventive Tips for Long-Term Reliability

Fixing planetary gear motor starting issues is great, but wouldn’t it be better if they never cropped up in the first place? Prevention’s the name of the game here—think of it like brushing your teeth to avoid the dentist. With a little routine care and some smart habits, you can keep your motor running like a dream, whether it’s powering a smart dispenser or a robotics arm. At Etonm Motor, we’ve seen firsthand how a few proactive steps can dodge those startup headaches. Here’s how to stay ahead of the curve and make reliability your motor’s middle name.

Routine Maintenance Musts

Motors thrive on TLC, so don’t skimp on the basics. Schedule regular checkups—every six months is a solid start—to spot wear before it snowballs. Peek at the gears for scuffs or chips, and give bearings a spin to catch any grumbles. Lubrication’s your MVP here; stick to the best planetary gear motor maintenance trick in the book—use the right grease, applied fresh, to keep friction at bay. Clean off dust or grime while you’re at it—a quick wipe-down can stop debris from gumming up the works. Skip this, and it’s like letting your car run on empty oil—trouble’s just waiting to knock.

Monitoring Like a Pro

Want to catch problems before they crash the party? Add some eyes to your setup. Slap on a vibration sensor—spikes mean something’s off, like a wobbly shaft or worn gear. Temperature probes are clutch, too; if it’s creeping past 60°C, you’ve got a heat issue brewing. Voltage and current monitors can flag electrical dips early—think of them as your motor’s personal smoke detector. These gadgets aren’t fancy; they’re cheap insurance. Tie them to a simple app or log, and you’ve got planetary gear motor troubleshooting tips at your fingertips. One factory we worked with cut breakdowns by 30% just by listening to the data.

No rocket science here—just good habits and a watchful eye. These steps don’t just prevent startup snafus; they stretch your motor’s lifespan and save you cash on repairs. Up next, we’ll share a real-world win that proves this stuff works. Ready to keep your motor in the game for the long haul? Let’s seal the deal.

Real-World Success: A Case Study

Theory’s nice, but nothing beats seeing planetary gear motor starting issues tackled in the wild. Take a busy warehouse we partnered with—a place where conveyor belts hum 24/7, powered by planetary gear motors from Etonm Motor. A few months back, they hit a wall: motors stalling at startup, orders piling up, and frustration boiling over. Sound familiar? We dug in, and what we found—and fixed—turned their headache into a win. Here’s the scoop on how we beat those common planetary gear motor problems and got things rolling again.

The trouble started with a triple whammy. First, the motors were hauling loads way beyond their spec—think a compact car towing a semi-truck. Second, lubrication was spotty; the grease had turned to sludge, gumming up the gears. Third, sloppy installation left the shafts misaligned, adding stress that made startups a coin toss. Downtime was spiking, and the team was ready to chuck the motors out the window.

We jumped in with a game plan. Step one: we split the load, rigging an extra motor to share the weight—no more overburdened heroes. Step two: we flushed out the old lube and switched to a high-grade grease, cutting friction like a hot knife through butter. Step three: a laser alignment tool got those shafts in line, dropping vibration to near zero. The result? Startup failures vanished, downtime slashed by 40%, and the motors ran cooler and longer. The warehouse manager even cracked a smile—rare stuff!

This wasn’t rocket science—just smart fixes, rooted in experience. It’s proof that nailing the basics can turn a mess into a success story. Next, we’ll wrap up with how you can do the same.

Conclusion

Dealing with planetary gear motor starting issues doesn’t have to feel like a losing battle. From electrical hiccups like low voltage to mechanical snags like overloaded gears—or even a misaligned shaft throwing everything off—we’ve walked through the why and the how-to-fix-it. With the right planetary gear motor troubleshooting tips, like checking your power supply, greasing up those gears, or tweaking your setup, you can turn a stubborn motor into a reliable workhorse. And as that warehouse case showed, a little know-how goes a long way—less downtime, happier motors, and maybe even a grin or two.

The trick? Don’t just react—get ahead of it. Regular maintenance, a watchful eye, and a motor that’s sized right for the job can keep those startup woes in the rearview. At Etonm Motor, we’re all about making that easy—whether it’s crafting the perfect planetary gear motor for your smart home gadget or robotics project. Curious about more tips or need a custom fix? Check out our Planetary Gear Motor page for specs and solutions, or drop us a line. Got a motor acting up? Let’s sort it out together—reach out today and keep things spinning!

Related Reading

- How to Maintain Gear Motors

- Comprehensive Guide to Low-Noise Gear Motors: Features, Types, and Applications

- Introduction of Planetary Gear Motor for Robot

- What is a BLDC Worm Gear Motor? A Comprehensive Guide for 2025

- How Do BLDC Worm Gear Motors Work? A Complete Guide

- How to Choose the Right Planetary Gear Motor for Your Application

- What Is a Gear Motor? Benefits and Uses by Etonm Motor

- Gear Motor Types and Applications Explained

- Planetary Gearbox Explained: How It Works

- Planetary Gear Motors vs. Spur Gear Motors: Which Wins?