Curious about the differences between helical worm gear motors and worm gear stepper motors? This guide breaks down their designs, performance, and best applications to help you choose the right motor for your project with Etonm Motor.

Table of Contents

Introduction

Picture this: You’re designing a sleek robotic arm for a smart home gadget, and it’s time to pick the motor. You’ve narrowed it down to a helical worm gear motor or a worm gear stepper motor—but which one’s the real MVP for your project? You’re not alone if you’ve ever scratched your head over motor specs. These two options might sound similar, but they’re built for different challenges, and choosing the right one can make or break your design.

In this guide, we’re diving into the nitty-gritty of helical worm gear motors versus worm gear stepper motors. We’ll unpack what sets them apart, from torque and efficiency to the applications they shine in—like robotics, sanitary dispensers, or even electric valves. Whether you’re a hobbyist tinkering in your garage or an engineer fine-tuning a prototype, we’ve got you covered. At Etonm Motor, we’ve spent years crafting custom motor solutions, so we know a thing or two about helping you find the perfect fit. Let’s break it down and figure out which motor deserves a spot in your next big idea.

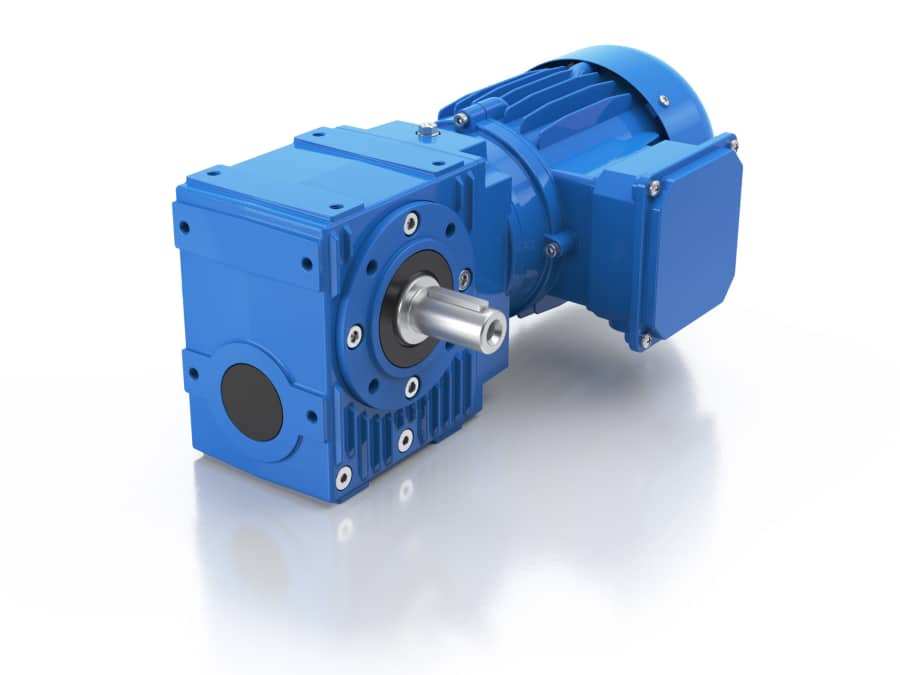

What Are Helical Worm Gear Motors?

When it comes to motors that pack a punch, helical worm gear motors are tough to beat. These little powerhouses combine the best of worm gear tech with a clever twist—literally. If you’re wondering what makes them special and where they fit into your projects, let’s dig in.

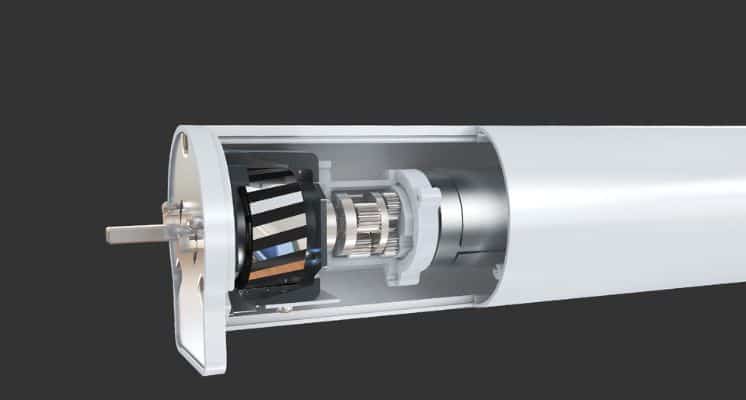

Design and Mechanics

At their core, helical worm gear motors pair a worm screw with a helical gear. Unlike standard worm gears, the helical design angles the teeth, boosting contact between the gear and screw. What’s the payoff? Higher efficiency and smoother operation. Studies suggest these motors can be up to 30% more efficient than traditional worm setups, thanks to reduced friction and wear. That means more power gets to where it’s needed—whether it’s turning a valve or driving a conveyor. Plus, they’re champs at delivering high torque in a compact package, which is why engineers love them for tight spaces.

Key Applications

So, where do these motors shine? Think heavy-duty tasks that need reliability—like powering sanitary dispensers or electric meters in smart home systems. They’re also a go-to for robotics, where consistent torque keeps movements steady. At Etonm Motor, we’ve seen clients use helical worm gear motors in everything from vending machines to medical equipment, proving their versatility. If your project demands strength without bulk, this might be your winner.

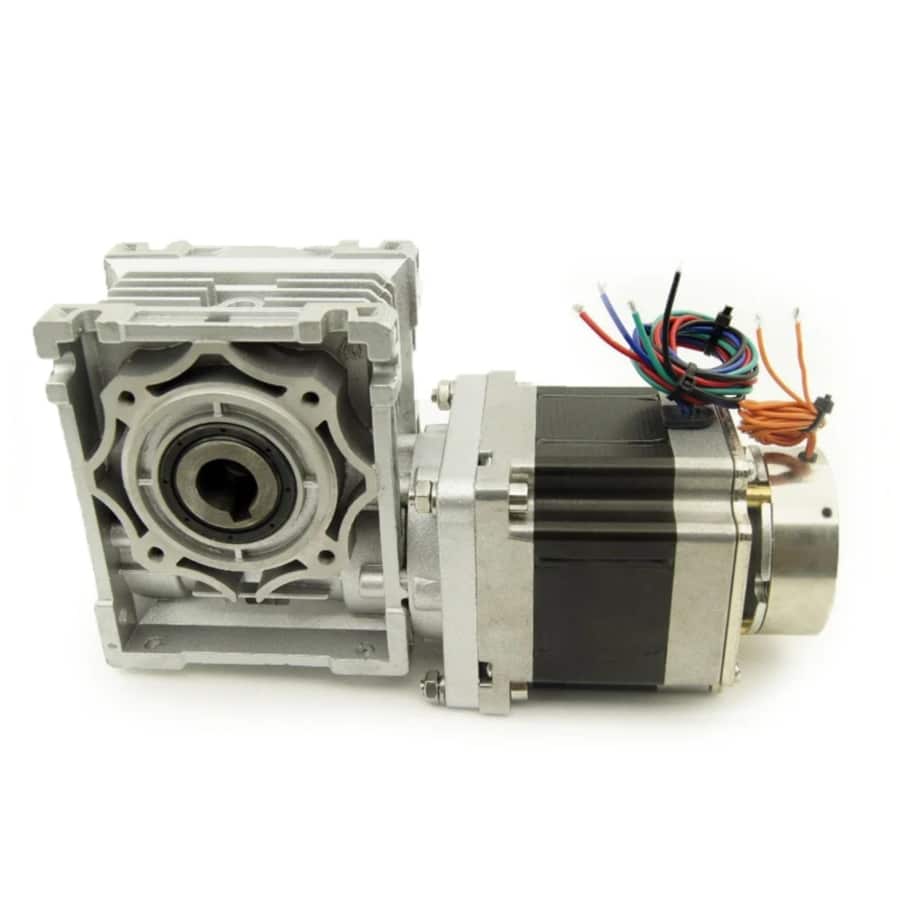

What Are Worm Gear Stepper Motors?

If precision is your game, worm gear stepper motors might just steal the show. These motors blend the pinpoint control of a stepper with the rugged simplicity of a worm gear. They’re not the fastest kids on the block, but when accuracy matters more than speed, they’re hard to top. Let’s break down what makes them tick and where they fit best.

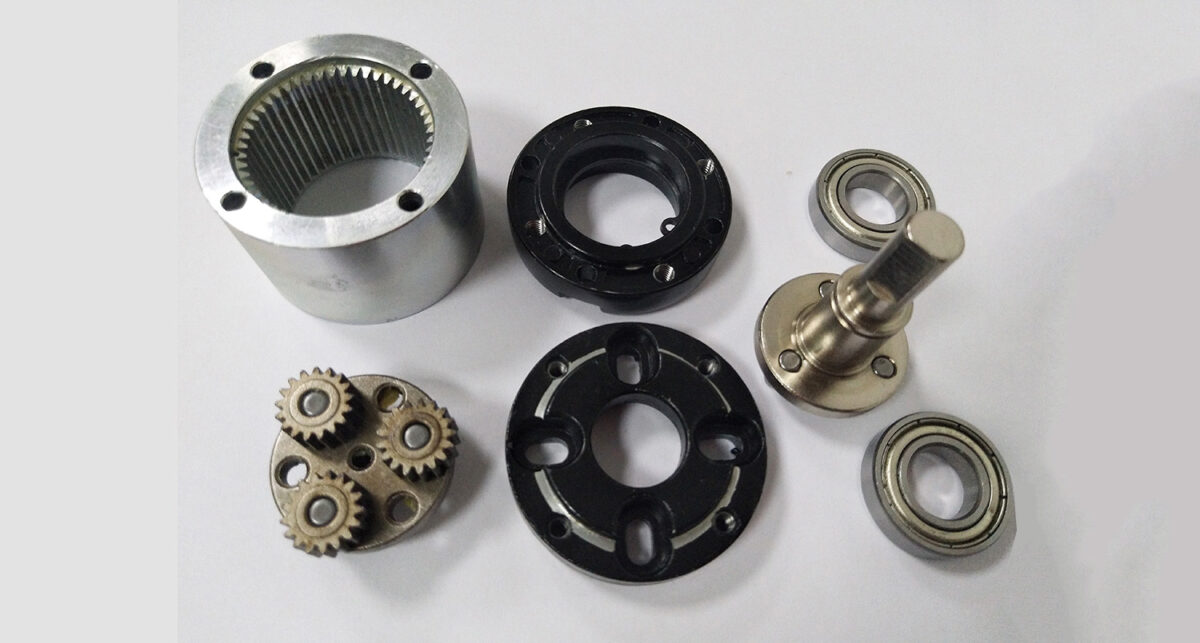

Design and Functionality

A worm gear stepper motor starts with a stepper motor—those trusty devices that move in tiny, exact steps. Add a worm gear into the mix, and you’ve got a setup that amplifies torque while keeping every movement deliberate. The worm screw meshes with a gear to lock motion in place, so there’s no slipping when power’s off. That’s a big win for applications needing rock-solid positioning. Sure, they sacrifice some speed—think tortoise, not hare—but the trade-off is control that’s spot-on, down to fractions of a degree. It’s a design that screams reliability over flash.

Common Uses

Where do these motors strut their stuff? Picture a vending machine dropping snacks with perfect timing or a smart home curtain sliding into place just so—these are worm gear stepper motor territory. They’re also favorites in medical devices, like pumps that need exact dosing, and small robotics projects where every step counts. At Etonm Motor, we’ve tailored these for clients who prioritize precision over raw power, and they rarely disappoint. If your project hinges on accuracy, this could be your go-to.

Head-to-Head Comparison

Now that we’ve met the players—helical worm gear motors and worm gear stepper motors—it’s time for the showdown. These two might share some DNA, but they’re built for different missions. Let’s stack them up across efficiency, cost, and use cases to see which one fits your next project like a glove.

Efficiency and Performance

First up, performance. Helical worm gear motors are the heavy lifters here. Their angled teeth cut friction, boosting efficiency—sometimes by as much as 30% over standard worm gears, according to engineering studies. That makes them champs at delivering high torque for demanding tasks. Worm gear stepper motors, though? They’re more about precision than power. Their step-by-step motion shines for accuracy, but speed takes a backseat, and efficiency dips under heavy loads. If your robotics arm needs brute strength, helical’s your guy. Need pinpoint control for a medical pump? Stepper’s got the edge.

Cost and Complexity

Let’s talk dollars and sense. Helical worm gear motors can cost more upfront—those helical gears aren’t cheap to craft—but their durability often pays off long-term. Worm gear stepper motors tend to be simpler and budget-friendly, especially for smaller setups. Installation’s a breeze with steppers too, while helical designs might need a bit more finesse. Curious about custom options? Check out Etonm’s custom gear motor solutions for a tailored fit either way.

Best Use Cases

So, who wins where? Helical worm gear motors dominate in high-torque gigs like sanitary dispensers or electric valves—think steady, reliable grunt work. Worm gear stepper motors rule precision zones: vending machines, smart home tweaks, or tiny bots that can’t miss a beat. A 2022 IEEE report on gear motor efficiency backs this up—helical excels in load-bearing, steppers in control. Your call depends on what’s priority: power or perfection.

Which Motor Should You Choose?

Alright, decision time. Helical worm gear motors and worm gear stepper motors both bring something awesome to the table, but picking the right one boils down to your project’s needs. Let’s cut through the noise and figure out which motor’s your match—because no one wants a square peg in a round hole.

Need raw power? Go helical. These motors thrive on high-torque challenges—think a sanitary dispenser pumping away or a robotic arm lifting heavy loads. Their efficiency and durability make them a solid pick for anything that demands muscle over finesse. On the flip side, if precision’s your priority, worm gear stepper motors are your best bet. They’re perfect for nailing exact movements, like a smart home gadget adjusting curtains or a vending machine dropping the right snack every time.

Still torn? Here’s a quick checklist:

- High torque or heavy loads? Helical worm gear motor.

- Tight precision or small steps? Worm gear stepper motor.

- Budget’s tight? Stepper’s often cheaper upfront.

- Long haul matters? Helical’s built to last.

At Etonm Motor, we’ve customized both for clients—whether it’s tweaking torque for robotics or dialing in accuracy for medical gear. Not sure what’s best? Dig into gear motor basics with this Engineering Toolbox guide for extra clarity. Whatever you choose, we’re here to make it work for you—just hit us up!

Conclusion

So, there you have it—helical worm gear motors versus worm gear stepper motors, unpacked and ready for your next move. If you’re chasing high torque and efficiency for heavy-duty tasks like robotics or electric valves, helical’s your heavy hitter. But if precision’s the name of your game—think smart home tweaks or medical devices—stepper’s the steady hand you need. Each shines in its own lane, and knowing the difference can save you headaches down the road.

At Etonm Motor, we’re all about matching the right motor to your vision, whether it’s off-the-shelf or custom-built. Still mulling it over? Explore our gear motor catalog for more options, or drop us a line to chat about what works best. Your project deserves a motor that fits just right—let’s make it happen!

Related Reading

- Understanding Worm Gear Motor Price: Factors, Trends, and Tips

- Gear Motor vs DC Motor vs Stepper Motor: Key Differences

- Spur Gear Motor vs. Worm Gear Motor: Which Is Best?

- Planetary Gear Motors vs. Spur Gear Motors: Which Wins?

- Planetary Gearbox Explained: How It Works

- Gear Motor Types and Applications Explained

- What Is a Gear Motor? Benefits and Uses by Etonm Motor

- Comparison of Commutation Methods in Brushless DC Motors: Sensor vs. Sensorless

- Brushless DC Motors vs. Brushed DC Motors: Key Advantages

- Outrunner vs. Inrunner: Which Brushless DC Motor Fits Your Needs?

- Brushless DC Motor vs. Servo Motor: What’s the Difference?

- AC Motors vs DC Motors: Which is Best for Your Application?