Choosing between a spur gear motor and a worm gear motor? Dive into this comparison to explore their differences, benefits, and ideal applications—brought to you by Etonm Motor.

Table of Contents

Introduction

If you’re knee-deep in designing a new robotics project or upgrading a smart home gadget, you’ve probably hit that moment of truth: picking the right gear motor. It’s not just about getting something that spins—it’s about finding the perfect fit for your needs. Two heavy hitters in the motor world often come up in this debate: spur gear motors and worm gear motors. But which one’s the real champ for your application? That’s what we’re here to unpack.

At Etonm Motor, we’ve spent years crafting custom solutions for everything from vending machines to medical devices, so we know a thing or two about what makes these motors tick. Spur gear motors bring speed and simplicity to the table, while worm gear motors flex their muscle with torque and control. Each has its sweet spot, and choosing between them can feel like picking your favorite child—tough, but doable with the right info. Stick with us as we break down the differences, perks, and ideal use cases to help you decide. Let’s dive in!

What Are Spur Gear Motors and Worm Gear Motors?

Before we jump into the nitty-gritty of picking a winner, let’s get a solid grip on what we’re dealing with. Spur gear motors and worm gear motors might both spin things around, but they’re built differently, and that changes everything—from how they perform to where they shine. Here’s the rundown.

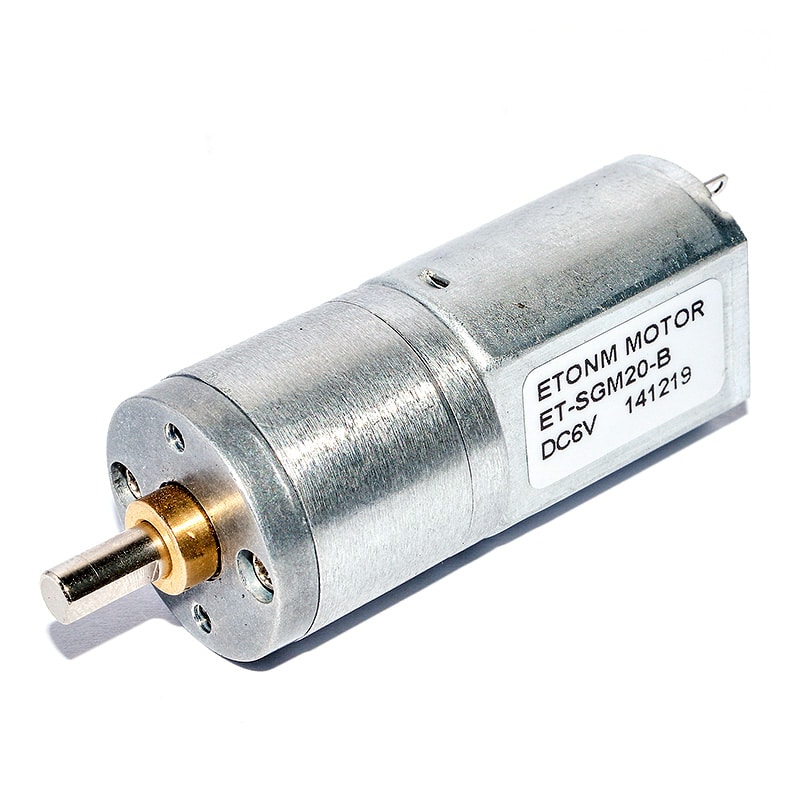

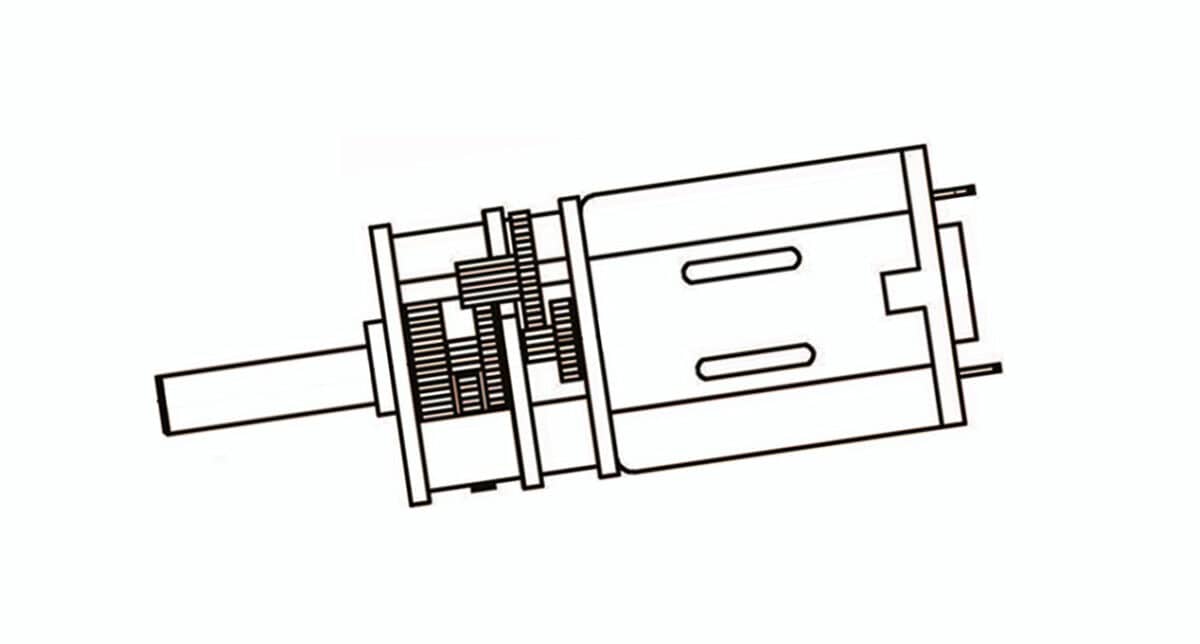

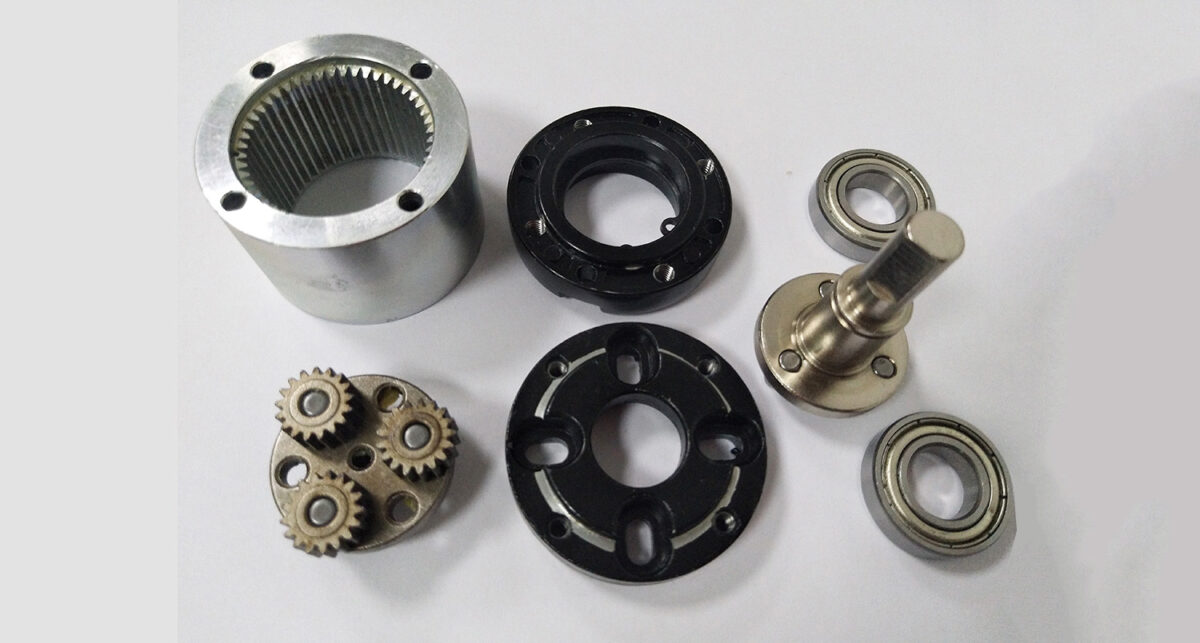

Spur Gear Motors Explained

Picture a spur gear motor as the straightforward, no-fuss option. It’s made up of gears with straight teeth mounted on parallel shafts, kind of like the gears you’d see in an old clock. Simple, right? That simplicity is its strength. Spur gear motors are champs at delivering high speed and solid efficiency—often hitting around 90% efficiency, according to engineering benchmarks. They’re lightweight, easy to produce, and perfect for jobs where smooth, fast motion is key. Think spur gear motor applications like powering a vending machine’s dispenser or a smart curtain system at home. At Etonm Motor, we’ve fine-tuned these for clients who need precision without the headache.

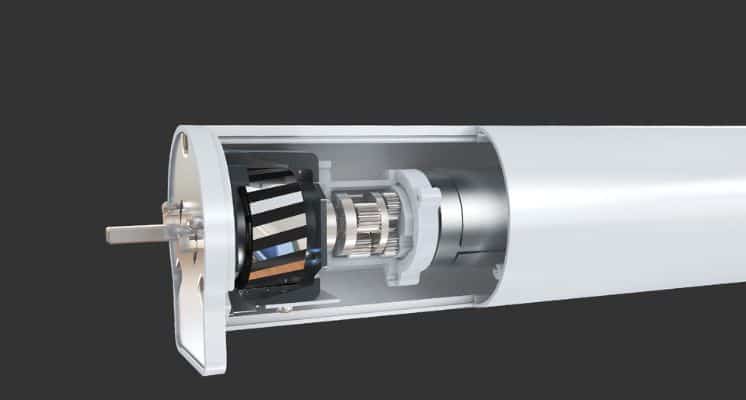

Worm Gear Motors Explained

Now, worm gear motors? They’re a different beast. Imagine a screw (the “worm”) turning a gear (the “wheel”)—that’s the setup. This design gives them a superpower: incredible torque in a compact package. They’re not as zippy as spur motors, and their efficiency dips—usually landing between 50-70% due to friction—but they make up for it with strength and control. Another perk? That worm screw can lock the gear in place when it stops, making it a go-to for safety-conscious setups. Worm gear motor efficiency might not wow you, but their knack for handling heavy loads shines in things like robotics arms or electric valves. We’ve seen them thrive in Etonm Motor projects like sanitary dispensers, where steady power is non-negotiable.

So, there’s your starting line: spur motors for speed and ease, worm motors for torque and grip. Next, we’ll dig into how those traits stack up head-to-head.

Key Differences Between Spur and Worm Gear Motors

Now that we’ve got the basics down, let’s put these two motors in the ring and see how they stack up. The gear motor comparison between spur and worm designs isn’t about declaring a universal champ—it’s about spotting what makes each one tick for your project. From efficiency to noise, here’s how they differ.

Efficiency and Performance

If efficiency’s your thing, spur gear motors take the crown. Thanks to their straightforward design, they can hit efficiency levels up to 90%, according to mechanical engineering studies—pretty impressive, right? They’re built for speed and smooth operation, making them a solid pick when you need quick, reliable motion. Worm gear motors, though? They trade some of that efficiency—often landing at 50-70%—for raw torque. That friction between the worm and gear slows them down but gives them serious lifting power. So, it’s a classic speed vs. strength showdown: spur motors zip along, while worm motors dig in deep.

Size and Design

Size matters, especially when space is tight. Worm gear motors have a knack for packing a punch in a compact footprint, thanks to their right-angle setup. That makes them a favorite for squeezing into tricky spots like robotics or valve systems. Spur gear motors, on the other hand, tend to be a bit more spread out with their parallel shafts. They’re simpler to build and tweak, which can keep costs down, but they might not fit as neatly into cramped designs. It’s all about what your blueprint can handle—cozy or roomy?

Noise and Maintenance

Here’s where things get real-world. Spur gear motors run quieter—those straight teeth mesh smoothly, keeping the hum low. That’s a win for stuff like smart home gadgets where silence is golden. Worm gear motors, though, can get a little chatty. The sliding action creates more friction, which means more noise and, over time, a bit more wear. You might need to grease them up now and then to keep them happy. Spur vs. worm gear advantages really show here: one’s a low-maintenance whisperer, the other’s a hardworking grunter.

These differences aren’t just tech specs—they’re the deciding factors for your next move. Let’s see where they fit best in the real world next.

Best Applications for Each Gear Motor Type

So, we’ve seen how spur and worm gear motors differ—now let’s talk about where they really shine. Picking the right one isn’t just about specs; it’s about matching the motor to your mission. Whether you’re building a robot or tweaking a smart home setup, here’s when each type steps up to the plate.

When to Choose a Spur Gear Motor

Spur gear motors are your go-to when speed and simplicity are non-negotiable. Need something to zip along without breaking the bank? These are perfect. Their high efficiency and smooth operation make them a natural fit for spur gear motor applications like vending machines—think a snack chute dropping your chips fast and flawlessly. They’re also big in smart home tech; at Etonm Motor, we’ve used them to power precise curtain systems that glide open at the tap of an app. If your project demands low torque but quick, reliable motion—say, a conveyor belt or a small pump—this is your guy. Plus, they’re quieter, so you won’t wake the house adjusting those blinds!

When to Choose a Worm Gear Motor

Worm gear motors, though, are the heavy lifters. When you need torque and control over speed, they’ve got your back. Their compact design and self-locking feature make them a top pick for best gear motor for robotics—imagine an arm lifting a load without slipping once the power’s off. At Etonm Motor, we’ve seen them excel in sanitary dispensers, delivering steady, powerful doses every time. They’re also clutch in electric valves or security systems where you need that extra oomph to handle resistance. Sure, they’re not as efficient, but when your job calls for strength over speed—like a medical device adjusting a bed—they’re tough to beat.

Knowing these sweet spots can save you headaches down the line. Let’s wrap it up with a quick pros-and-cons cheat sheet next.

Pros and Cons at a Glance

Alright, let’s boil it all down. Choosing between a spur gear motor and a worm gear motor can feel like a tug-of-war between what you need now and what’ll work long-term. Here’s a quick snapshot of their spur vs. worm gear advantages—and drawbacks—so you can see them side by side and pick your player.

- Spur Gear Motors

- Pros: High efficiency (up to 90%), fast and smooth operation, low noise, cost-effective, easy to maintain. Perfect for speedy, light-duty tasks.

- Cons: Limited torque—don’t expect it to lift the heavy stuff. Less compact, so it might hog a bit more space.

- Spur Gear Motors

- Worm Gear Motors

- Pros: Killer torque, compact design, self-locking for safety, great for tight spaces or heavy loads. A champ in control-focused jobs.

- Cons: Lower efficiency (50-70%), noisier, and that friction means more upkeep. Not the speed king, either.

- Worm Gear Motors

Think of it like this: spur gear motors are the sprinters—quick, quiet, and budget-friendly. Worm gear motors are the weightlifters—strong, steady, and ready for a challenge. At Etonm Motor, we’ve got both in our playbook, so whichever you lean toward, we can tweak it to fit. Ready to make your call? Let’s tie it all together next.

Conclusion

So, where do we land in the spur gear motor vs. worm gear motor debate? It’s less about a knockout winner and more about what your project’s yelling for. Spur gear motors bring the speed, efficiency, and quiet vibes—ideal if you’re powering something like a smart home gadget or a zippy conveyor. Worm gear motors flex their torque and control, making them the heavy-duty choice for robotics or valves that need to hold steady. Each has its groove, and knowing the trade-offs is half the battle.

Still scratching your head over which one’s your match? Head over to Etonm Motor’s gear motor catalog to scope out our full lineup—there’s more where this came from! Or, drop us a line for a custom solution tailored just for you. Your perfect motor’s out there, and honestly, it’s probably just a conversation away. Let’s make it happen!

Related Reading

- Understanding Worm Gear Motor Price: Factors, Trends, and Tips

- Gear Motor vs DC Motor vs Stepper Motor: Key Differences

- Helical Worm Gear Motor vs. Worm Gear Stepper Motor

- Planetary Gear Motors vs. Spur Gear Motors: Which Wins?

- Planetary Gearbox Explained: How It Works

- Gear Motor Types and Applications Explained

- What Is a Gear Motor? Benefits and Uses by Etonm Motor

- Brushless DC Motors vs. Brushed DC Motors: Key Advantages

- Brushless DC Motor vs. Servo Motor: What’s the Difference?

- What is a BLDC Worm Gear Motor? A Comprehensive Guide for 2025

- How Do BLDC Worm Gear Motors Work? A Complete Guide

- AC Motors vs DC Motors: Which is Best for Your Application?

- BLDC Motor vs Brushed Motor: Which is Better for Your Needs?