"Explore the benefits, working principles, and selection criteria for brushless planetary gear motors. Etonm Motor provides expert insights for your projects."

Table of Contents

Introduction

Are you searching for a motor that’s efficient, precise, and tough enough to handle your toughest projects? If so, let me introduce you to the world of brushless planetary gear motors. These little powerhouses combine the best of brushless DC technology with the muscle of a planetary gear system, delivering a one-two punch of performance that’s hard to beat. Whether you’re building a robotic arm, designing an automated conveyor, or crafting the next big thing in smart home tech, a brushless planetary gear motor might just be the game-changer you need.

So, what makes these motors so special? Picture this: a brushless DC motor—known for its efficiency and long life—teamed up with a planetary gearbox that cranks up torque while keeping things compact. It’s like the motor equivalent of a Swiss Army knife—versatile, reliable, and ready for action. At Etonm Motor, we’ve seen firsthand how these bldc planetary gear motors shine in industries like robotics, medical equipment, and even electric vehicles. They’re quiet, they’re powerful, and they’re built to last.

In this article, we’ll dive into what brushless planetary gear motors are, why they outperform other options, where they’re making a difference, and how to pick the right one for your needs. Stick around—whether you’re a seasoned engineer or just curious about motor tech, there’s something here for you. Let’s get started!

What Are Brushless Planetary Gear Motors?

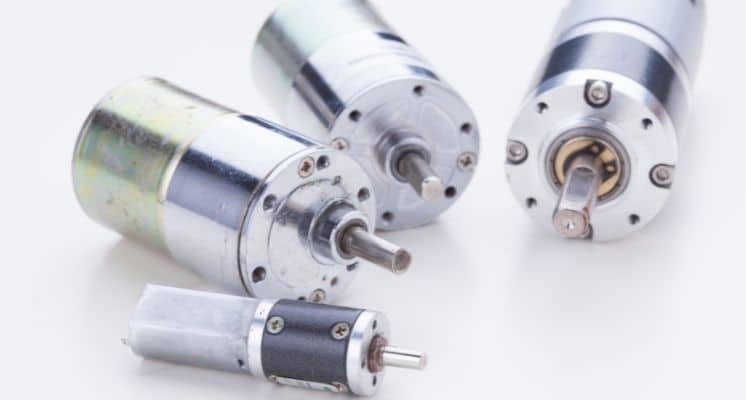

Let’s break it down: brushless planetary gear motors sound fancy, but they’re really just a brilliant mash-up of two proven technologies working together. If you’ve ever wondered how a motor can be both powerful and precise without taking up too much space, this is your answer. These motors are the go-to choice for engineers who need reliability and performance in one neat package. So, how do they work? Let’s dig into the details.

Understanding Brushless DC Motors

First up, the brushless DC motor—or BLDC for short—is the heart of this setup. Unlike traditional brushed motors, which rely on physical brushes to transfer power (and wear out over time), a brushless DC motor with a planetary gearbox uses electronic controls to keep things spinning. This means fewer moving parts, less friction, and a motor that can run cooler and longer—sometimes up to 10,000 hours or more, depending on the load. Efficiency? We’re talking 85% to 95%, which is a big step up from the 75%-80% you might get with brushed alternatives. It’s no wonder these motors are a favorite for applications where downtime isn’t an option.

The Role of Planetary Gear Systems

Now, let’s add the planetary gearbox for brushless motor into the mix. Picture a tiny solar system: a central “sun” gear surrounded by “planet” gears, all nestled inside a ring gear. This clever design spreads the load across multiple gears, boosting torque—think 3:1 to 1000:1 gear ratios—while keeping the whole thing compact. That’s why a brushless motor with planetary gearbox can deliver serious power without bulking up your design. Plus, the setup naturally reduces backlash (that annoying wiggle in gear systems), making it perfect for precise movements, like positioning a robotic arm or fine-tuning a medical device.

Why They Work So Well Together

When you pair a brushless DC planetary gear motor with its planetary gearbox, magic happens. The brushless motor brings efficiency and smooth operation, while the gearbox amplifies torque and keeps everything tight and controlled. The result? A brushless and dc planetary gear motor that’s quiet, durable, and ready to tackle high-torque tasks in tight spaces. At Etonm Motor, we’ve fine-tuned these motors for everything from vending machines to surgical tools, proving they’re as versatile as they are tough.

In short, brushless planetary gear motors aren’t just a motor—they’re a solution. Whether you’re chasing efficiency, precision, or raw power, this combo has you covered.

Advantages of Brushless Planetary Gear Motors

When it comes to motors, brushless planetary gear motors are like the overachievers of the class—quietly stealing the show with their standout qualities. They’re not just another option on the shelf; they bring a unique mix of benefits that make them a top pick for engineers and designers alike. From jaw-dropping efficiency to pinpoint precision, here’s why these motors are worth your attention.

1. Efficiency and Longevity

Let’s start with the numbers: a brushless DC motor with a planetary gearbox can hit efficiency levels of 85% to 95%. Compare that to brushed motors, which often hover around 75%-80%, and you’re looking at less wasted energy and lower operating costs. Why? No brushes mean no friction to wear things down. That translates to a lifespan that can stretch beyond 10,000 hours—sometimes double what a brushed motor might manage. At Etonm Motor, we’ve seen these bldc planetary gear motors keep running smoothly in applications like vending machines and sanitary dispensers, where downtime is a dealbreaker. Less maintenance, more uptime—it’s a win-win.

2. Precision and Control

If you need a motor that nails accuracy, brushless and DC planetary gear motors deliver. Thanks to the planetary gearbox, you get low backlash—often under 1-2 degrees—meaning almost no slop in the system. That’s a big deal for robotics, where a fraction of a degree can mean the difference between a perfect weld and a miss. Pair that with the brushless design’s smooth, electronically controlled operation, and you’ve got a motor that’s as precise as a surgeon’s hand. Whether it’s adjusting a security camera or powering a medical pump, these motors keep things steady and on point.

3. Compactness and Torque Density

Here’s where the planetary gearbox for the brushless motor really flexes its muscles. The multi-gear setup cranks up torque—think 0.1kg.cm to 500kg.cm, depending on the model—without turning your design into a bulky mess. Gear ratios from 3:1 to 1000:1 let you fine-tune the output, so you get big power in a small package. Imagine fitting a brushless motor with a planetary gearbox into a sleek electric wheelchair or a compact drone—it’s all about high torque density without the extra baggage. Compared to a stepper motor, these beauties maintain torque at higher speeds, making them a smarter choice for dynamic applications.

4. Why They Stand Out

Put it all together, and brushless planetary gear motors offer a trifecta: efficiency, precision, and power in a tight footprint. They run quieter than brushed motors (no buzzing brushes!), handle heavy loads without breaking a sweat, and last longer under pressure. Sure, they might cost a bit more upfront, but the payoff in performance and reliability is hard to argue with. At Etonm Motor, we’ve tailored these motors for clients across the globe—82% of our sales go to the US and EU—proving they’re a trusted solution for real-world challenges.

Application Areas of Brushless Planetary Gear Motors

If there’s one thing brushless planetary gear motors prove, it’s that great things come in small packages. These motors are popping up everywhere, from high-tech labs to your everyday gadgets, thanks to their knack for blending power, precision, and efficiency. At Etonm Motor, we’ve seen them tackle some pretty cool challenges across industries. Let’s take a tour of where these brushless DC planetary gear motors are making their mark.

Industry Applications

- Robotics: Precision is king here, and brushless planetary gear motors deliver. Whether it’s a robotic arm assembling parts or a drone adjusting its flight path, these motors provide the torque (up to 500kg.cm) and low-backlash control needed for spot-on movements. Their quiet operation is a bonus—no one wants a buzzing bot in the room.

- Automation: Think conveyor belts, packaging machines, or smart vending systems. A brushless motor with planetary gearbox keeps things moving smoothly with high efficiency—up to 95%—and minimal maintenance. That’s why they’re a staple in factories where uptime is everything.

- Medical Equipment: From surgical robots to infusion pumps, bldc planetary gear motors shine in healthcare. Their compact size fits into tight designs, while their long lifespan (over 10,000 hours) and silent running make them ideal for devices patients rely on daily.

- Electric Vehicles: Electric scooters, wheelchairs, and even small EVs lean on brushless and dc planetary gear motors for their torque density. Need to climb a hill or haul a load? The planetary gearbox kicks in, delivering power without bulking up the frame.

- Security Systems: Ever wonder how a surveillance camera pans so smoothly? A brushless DC motor with planetary gearbox is often the unsung hero, offering precise positioning and durability in outdoor conditions. Same goes for smart locks—small, strong, and reliable.

- Consumer Electronics: Toys, smart home gadgets, and even electric toothbrushes tap into these motors. The planetary gearbox for brushless motor keeps them compact and efficient, while the brushless design cuts noise—perfect for keeping your mornings peaceful.

Why They Fit So Well

What ties these applications together? It’s the brushless planetary gear motor superpower: delivering high torque and precision in a package that doesn’t hog space. In robotics, it’s about accuracy; in EVs, it’s efficiency (think 90%+); in medical gear, it’s reliability. Take Etonm Motor’s work as an example—we’ve customized these motors for clients needing everything from a 12V robot arm to a 6V smart dispenser, proving they’re as flexible as they are tough. With diameters from 8mm to 51mm and voltages from 1V to 30V, there’s a fit for almost any job.

Real-World Impact

Consider this: a robotics company using a brushless motor with planetary gearbox cut their maintenance costs by 30% compared to brushed motors, thanks to the longer lifespan. Or picture a medical device running flawlessly for years, powered by a motor that doesn’t quit. These aren’t just motors—they’re problem-solvers. Curious about specs? Check out our product page for details on how we tailor them to your needs.

How to Choose the Right Brushless Planetary Gear Motor

Picking the perfect brushless planetary gear motor isn’t rocket science, but it does take a bit of know-how to match it to your project. With so many options out there, from torque ratings to gear ratios, it’s easy to feel overwhelmed. Don’t worry—I’ve got you covered with some practical tips to make the process a breeze. Whether you’re powering a robot or a smart lock, here’s what you need to consider to get the most out of a brushless DC motor with a planetary gearbox.

Key Selection Factors

- Torque Needs: Start with the heavy lifting—literally. How much torque does your application demand? A planetary gearbox for brushless motor can deliver anywhere from 0.1kg.cm to 500kg.cm, depending on the gear ratio (3:1 to 1000:1). Pro tip: overshoot your requirement by 10%-20% to avoid strain. For example, a robotic arm lifting 5kg might need a 50kg.cm motor to play it safe.

- Speed Requirements: Speed and torque go hand in hand. Higher gear ratios mean more torque but lower RPMs. A brushless DC planetary gear motor lets you dial it in—say, 100 RPM for a conveyor or 10 RPM for a precision tool. Check your output needs and match the motor’s base speed (often 1000-3000 RPM) to the gearbox reduction.

- Voltage Compatibility: Power supply matters. At Etonm Motor, our bldc planetary gear motors range from 1V to 30V. A 12V motor might suit a robot, while a 6V option fits a handheld gadget. Make sure your system’s voltage aligns—mismatches can fry your setup or leave it underpowered.

- Size and Weight: Space tight? These motors shine here. Diameters from 8mm to 51mm mean a brushless motor with a planetary gearbox can squeeze into anything from a drone to an industrial rig. Measure your mounting area and keep weight in mind, especially for mobile applications like EVs.

- Environmental Conditions: Where’s this motor living? Dust, humidity, or extreme temperatures (say, -20°C to 80°C) can affect performance. A brushless and DC planetary gear motor is tough, but check IP ratings if it’s facing harsh conditions—like an outdoor security camera.

- Control Options: Need precision? Add-ons like encoders or brakes can level up a brushless planetary gear motor. Encoders track position for robotics; brakes hold loads in place. Chat with a supplier like Etonm Motor to customize these extras for your build.

Practical Tips for Success

Here’s a quick checklist: Map out your torque and speed, double-check the voltage, measure your space, and factor in the environment. Still unsure? Etonm Motor’s team can tweak a brushless motor with planetary gearbox to your exact specs—think custom gear ratios or specific diameters. We’ve done it for clients powering everything from medical pumps to smart home devices. Want to see the range? Peek at our custom solutions page.

Avoid Common Pitfalls

Don’t skimp on torque—underpowered motors burn out fast. Don’t ignore heat buildup; brushless designs run cooler, but heavy loads need ventilation. Get these right, and your brushless planetary gear motors will hum along happily for years—10,000 hours or more.

Choosing the right motor is about fit, not just features. Nail these factors, and you’ll have a powerhouse tailored to your project.

Conclusion

So, there you have it—brushless planetary gear motors in all their glory. These motors aren’t just another cog in the machine; they’re a powerhouse combo of efficiency, precision, and versatility that can tackle everything from robotics to smart home gadgets. With efficiency hitting up to 95%, torque that packs a punch (0.1kg.cm to 500kg.cm), and a lifespan that stretches past 10,000 hours, it’s clear why they’re a favorite across industries. Whether you’re after a brushless DC motor with planetary gearbox for a sleek EV or a bldc planetary gear motor for a whisper-quiet medical device, they’ve got the goods.

At Etonm Motor, we’ve poured years into perfecting these motors—customizing them for clients from the US to the EU, where 82% of our sales land. Need a 12V motor for a robot arm or a tiny 8mm-diameter option for a security lock? We’ve got you covered with voltages from 1V to 30V and sizes from 8mm to 51mm. It’s not just about selling motors; it’s about solving problems with tailor-made solutions that fit your project like a glove.

Ready to power up your next big idea? Swing by our website to explore the full range of brushless planetary gear motors or drop us a line for a custom quote. Don’t settle for off-the-shelf when you can have a motor built for you. Let’s make something awesome together—because with the right brushless motor with planetary gearbox, the sky’s the limit!

Related Reading

- Low RPM Brushless Motor: Technical Specs & Customization

- Gear Motor Applications: Top Uses Explored

- 24v Planetary Gear Motor: Strength Meets Efficiency

- 12v DC Planetary Gear Motor: Power & Precision by Etonm Motor

- Planetary Gear Motor Explained: Benefits & Uses

- Micro and Mini Planetary Gear Motors: Power in Compact Design

- Gear Reduction Motors Explained: Types, Uses & Selection Tips

- Small Gear Motors: Key Differences Explained

- How to Choose a Gear Motor for Your Project

- What is a Planetary Gear Motor Used For?

- Gear Motor vs DC Motor vs Stepper Motor: Key Differences

- Planetary Gear Motors vs. Spur Gear Motors: Which Wins?

- Planetary Gearbox Explained: How It Works

- What Are the Key Advantages of Brushless Motors?

- How to Choose the Right Planetary Gear Motor for Your Application

- How to Choose the Right Brushless Gear Motor for Your Application