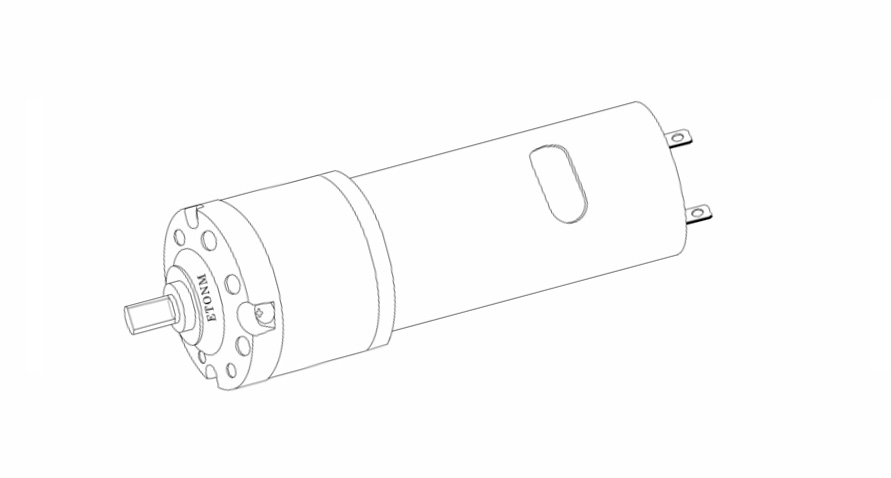

Discover how Etonm Motor’s custom 12V DC motors deliver high torque and precision at 2000 RPM, perfect for industrial and DIY applications.

Table of Contents

Introduction

When it comes to powering industrial equipment, robotics, or even complex DIY projects, having the right motor can make all the difference. For professionals who demand precision, reliability, and high performance, a 12V DC motor with high torque and 2000 RPM is often the ideal solution. But not all motors are created equal—off-the-shelf options may fall short when your application requires specific features, such as a custom 8mm shaft or tailored torque output.

This is where customization becomes critical. At Etonm Motor, we specialize in designing and manufacturing high-performance 12V DC motors that meet the unique needs of our clients. Whether you’re working on smart home devices, medical equipment, or advanced robotics, our motors are engineered to deliver the perfect balance of power, speed, and durability. With a focus on high torque and precise 2000 RPM performance, our custom motors ensure your projects run smoothly and efficiently.

In this article, we’ll explore the benefits of high torque 12V DC motors, the versatility of 8mm shaft designs, and how Etonm Motor’s tailored solutions can help you achieve your goals. Let’s dive into the world of custom power solutions and discover why professionals trust Etonm Motor for their most demanding applications.

High-Performance Design – Torque and RPM Optimization

Regarding motors, performance is all about finding the right balance between torque and RPM (revolutions per minute). For professionals working in industries like robotics, industrial automation, or even advanced DIY projects, a 12V DC motor with high torque and 2000 RPM is often the sweet spot. But what makes this combination so powerful, and how does Etonm Motor optimize these features to meet your specific needs?

Why High Torque Matters

Torque is the force that allows a motor to perform work—whether it’s lifting, pushing, or driving a mechanism. In applications like electric valves, vending machines, or robotic arms, high torque ensures that the motor can handle heavy loads without stalling or overheating. For example, a 12V DC motor with high torque is essential for devices that require consistent power output, even under demanding conditions.

At Etonm Motor, we design our motors to deliver exceptional torque without compromising efficiency. Our engineers use advanced materials and precision engineering to ensure that every motor can handle the toughest tasks, from industrial machinery to medical devices.

The Role of 2000 RPM in Precision Applications

While torque provides the muscle, RPM determines the speed at which your motor operates. A 12V DC motor with 2000 RPM offers the perfect blend of speed and control, making it ideal for applications that require both power and precision. For instance, in security systems or sanitary dispensers, a motor with 2000 RPM ensures smooth, reliable operation without unnecessary noise or vibration.

Etonm Motor’s custom motors are optimized to maintain consistent RPM levels, even under varying loads. This stability is crucial for applications where precision is non-negotiable, such as in medical care equipment or automated manufacturing systems.

Customization for Peak Performance

What sets Etonm Motor apart is our ability to tailor these performance features to your exact requirements. Whether you need a 12V DC motor with high torque for heavy-duty industrial use or a 2000 RPM motor for delicate, high-precision tasks, we can customize the design to match your application. Our team works closely with you to understand your needs, ensuring that every motor we produce delivers optimal performance.

For example, if your project requires a motor to operate in extreme temperatures or harsh environments, we can incorporate specialized materials and coatings to enhance durability. Or, if you need a compact motor with high torque for a smart home device, we can design a solution that fits seamlessly into your product.

Real-World Applications

- Industrial Equipment: High torque motors power conveyor belts, pumps, and heavy machinery.

- Robotics: Precision motors with 2000 RPM enable smooth, accurate movements in robotic arms and automated systems.

- Medical Devices: Reliable, high-performance motors are critical for diagnostic equipment and patient care tools.

By combining high torque and 2000 RPM in a single motor, Etonm Motor provides a versatile solution that meets the demands of modern technology. Whether you’re building the next generation of smart devices or upgrading industrial equipment, our custom motors are designed to deliver unmatched performance.

Custom Shaft Applications – Versatility in Industrial and DIY Projects

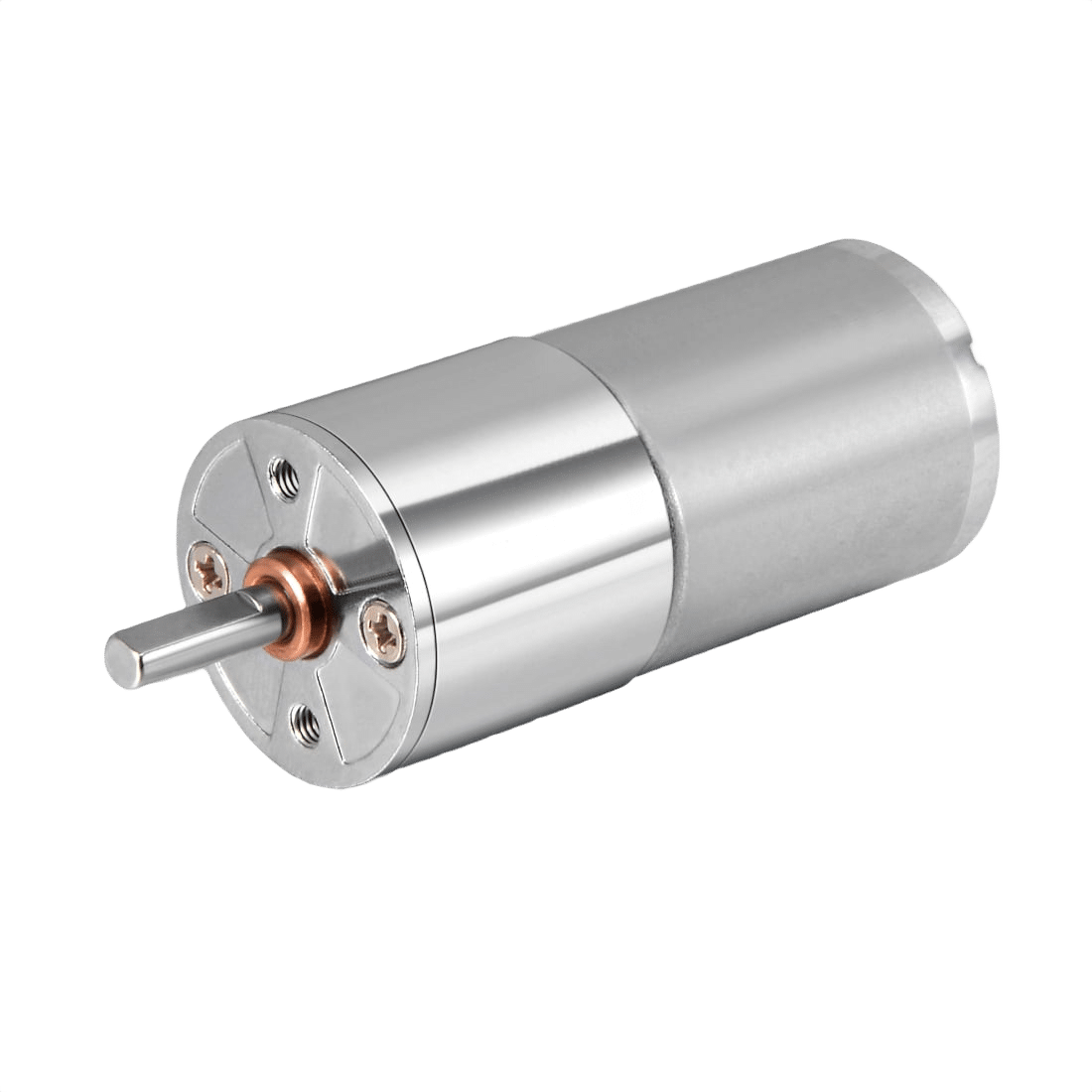

When designing a motor for specialized applications, even the smallest details can greatly impact performance. One such detail is the shaft—the component that transfers the motor’s rotational force to the rest of the mechanism. For many professionals, a 12V DC motor with an 8mm shaft is the perfect choice, offering the ideal balance of strength, precision, and compatibility. But what makes this shaft size so versatile, and how can it be customized to meet your specific needs?

Why an 8mm Shaft?

The 8mm shaft is a popular choice for a wide range of applications because it strikes the perfect balance between durability and flexibility. It’s robust enough to handle high torque loads, yet compact enough to fit into space-constrained designs. Whether you’re working on industrial machinery, robotics, or DIY projects, an 8mm shaft ensures reliable power transmission without unnecessary bulk.

At Etonm Motor, we understand that every project is unique. That’s why we offer custom 8mm shafts tailored to your exact specifications. From material selection to surface finishing, we can optimize the shaft to meet the demands of your application.

Industrial Applications

In industrial settings, motors with 8mm shafts are often used in equipment that requires precise motion control and high reliability. For example:

Conveyor Systems: An 8mm shaft can efficiently transfer power to conveyor belts, ensuring smooth and consistent operation.

Electric Valves: High torque motors with 8mm shafts are ideal for controlling the flow of liquids or gases in industrial pipelines.

Automated Machinery: From assembly lines to packaging systems, these motors provide the precision and durability needed for continuous operation.

DIY and Hobbyist Projects

For DIY enthusiasts and hobbyists, a 12V DC motor with an 8mm shaft opens up a world of possibilities. Whether you’re building a custom robot, a miniature vehicle, or a home automation system, these motors offer the perfect combination of power and versatility. Their compact size and high torque output make them ideal for projects that require both strength and precision.

Customization Options

At Etonm Motor, we go beyond standard designs to offer fully customizable shafts. Here’s how we can tailor an 8mm shaft to your needs:

Material Selection: Choose from high-strength steel, stainless steel, or other materials to match your application’s requirements.

Surface Finishing: Options like polishing, coating, or heat treatment can enhance durability and reduce wear.

Keyway or D-Shape: We can modify the shaft to include keyways or D-shaped profiles for secure coupling with other components.

Real-World Examples

Robotics: A custom 8mm shaft ensures precise movement in robotic arms and joints.

Smart Home Devices: Compact motors with 8mm shafts power everything from automated blinds to smart locks.

Medical Equipment: High-precision motors with custom shafts are used in diagnostic tools and patient care devices.

By offering custom 8mm shafts, Etonm Motor ensures that your motor is perfectly suited to your application. Whether you’re tackling an industrial challenge or embarking on a creative DIY project, our motors provide the reliability and performance you need.

How to Choose the Right Custom Motor

Selecting the perfect motor for your application can feel overwhelming, especially when you need a 12V DC motor with high torque, 2000 RPM, and an 8mm shaft. With so many options available, how do you ensure you’re making the right choice? The key lies in understanding your specific requirements and working with a supplier who can deliver a truly customized solution. Here’s a step-by-step guide to help you navigate the process.

Step 1: Define Your Application Requirements

Before diving into motor specifications, take the time to clearly define your application’s needs. Ask yourself:

- What is the primary function of the motor? (e.g., lifting, rotating, driving)

- What are the load and speed requirements? (e.g., high torque, 2000 RPM)

- Are there space or weight constraints? (e.g., compact design, lightweight)

- Will the motor operate in harsh environments? (e.g., high temperatures, moisture)

For example, if you’re designing a robotic arm, you’ll need a motor with high torque and precise speed control. On the other hand, a sanitary dispenser might require a compact motor with an 8mm shaft for easy integration.

Step 2: Prioritize Key Features

Once you’ve defined your requirements, prioritize the features that matter most. For many professionals, the following are critical:

- High Torque: Essential for heavy-duty applications like industrial machinery or electric valves.

- 2000 RPM: Ideal for tasks that require a balance of speed and precision, such as robotics or medical devices.

- 8mm Shaft: Offers versatility and compatibility with a wide range of components.

At Etonm Motor, we specialize in tailoring these features to your exact needs, ensuring your motor performs flawlessly in your application.

Step 3: Communicate with Your Supplier

Customization is a collaborative process. When working with a supplier like Etonm Motor, clear communication is key. Be prepared to share:

- Detailed specifications (e.g., torque, RPM, shaft size)

- Environmental conditions (e.g., temperature, humidity)

- Any special requirements (e.g., noise reduction, energy efficiency)

Our team of experts will work closely with you to refine the design and ensure the motor meets your expectations. Whether you need a 12V DC motor with high torque for industrial use or a custom 8mm shaft for a DIY project, we’re here to help.

Step 4: Test and Validate

Before finalizing your order, it’s important to test the motor to ensure it performs as expected. At Etonm Motor, we offer prototyping and testing services to validate the design. This step helps identify any potential issues and ensures the motor is perfectly suited to your application.

Why Choose Etonm Motor?

- Expertise: With years of experience in custom motor design, we understand the unique challenges of various industries.

- Quality: Our motors are built to the highest standards, ensuring reliability and durability.

- Customer Support: From initial consultation to after-sales service, we’re committed to your success.

By following these steps and partnering with a trusted supplier like Etonm Motor, you can confidently select a 12V DC motor that delivers the performance, precision, and reliability your project demands.

Conclusion – Etonm Motor’s Personalized High-Performance Solutions

In today’s fast-paced world, where precision, power, and reliability are non-negotiable, having the right motor can make or break your project. Whether you’re designing cutting-edge robotics, optimizing industrial machinery, or bringing a creative DIY project to life, a 12V DC motor with high torque, 2000 RPM, and an 8mm shaft offers the perfect combination of performance and versatility. But why settle for off-the-shelf solutions when you can have a motor tailored to your exact needs?

At Etonm Motor, we pride ourselves on delivering customized high-performance motors that meet the unique demands of professionals across industries. From the initial design phase to the final product, our team works closely with you to ensure every detail—whether it’s torque, RPM, or shaft size—is optimized for your application. Our commitment to quality, innovation, and customer satisfaction sets us apart as a trusted partner in the world of custom motors.

Why Choose Etonm Motor?

Tailored Solutions: We don’t believe in one-size-fits-all. Every motor we produce is designed to meet your specific requirements.

Advanced Engineering: Our motors are built using state-of-the-art technology and high-quality materials, ensuring durability and efficiency.

Expert Support: From concept to completion, our team is here to guide you every step of the way.

Take the Next Step

Ready to power your project with a motor that’s as unique as your vision? Explore our range of custom DC motors and discover how Etonm Motor can help you achieve your goals. Whether you need a high torque motor for industrial use or a compact 8mm shaft motor for DIY projects, we’ve got you covered.

Explore More 12v DC Motors

Related Reading

- 1000 RPM and Beyond: High Performance 12V DC Motors

- 12V High Torque DC Motors: Your Guide to Power and Precision

- High Torque Gear Motors: Unleashing 12V Power for Robotics

- 12V DC Motor High Torque High RPM: Torque vs. Speed

- Low RPM Brushless Motor: Technical Specs & Customization

- 12V DC Motor High Torque Low RPM Performance

- 12V Low Speed High Torque Motor: Ideal For DIY Projects

- Small But Mighty: Mastering Small High Torque 12V Motors