“Discover how pairing 12V DC motors with speed controllers and encoders boosts precision in robotics, smart devices, and more with Etonm Motor’s custom solutions.”

Table of Contents

Unlocking the Power of 12V DC Motors with Accessories

When it comes to powering small machines or smart devices, 12V DC motors are a go-to choice for their versatility and compact size. But what if you could push their performance further? That’s where a 12V DC motor speed controller and a 12V DC motor with an encoder step in. These accessories don’t just tweak how your motor runs—they transform it into a precise, efficient system tailored to your project. Whether you’re building a robotic arm, a smart home gadget, or an industrial tool, pairing speed control with encoder feedback makes all the difference.

Imagine a motor that spins reliably but lacks the finesse for tight turns or steady speeds. Add a speed controller to set the exact RPMs you need, then pair it with an encoder to track every move. Suddenly, you’re not just running a motor—you’re commanding a system. In this post, we’ll dive into how these tools unlock new possibilities for 12V DC motors and why Etonm Motor’s custom solutions stand out. Ready to see what precision control can do? Let’s get started.

How Speed Controllers and Encoders Work Together

Pairing a 12V DC motor with the right accessories turns a simple power source into a finely tuned machine. The real magic happens when a 12V DC motor speed controller teams up with a 12V DC motor with encoder. Together, they deliver power and precision—exactly what engineers, hobbyists, and innovators need. Here’s how they make it happen.

The Role of a 12V DC Motor Speed Controller

A 12V DC motor speed controller acts like a throttle on a car—it lets you decide how fast or slow your motor runs. Using voltage adjustments or pulse width modulation (PWM), it gives you full control over RPMs. Need a slow pace for a conveyor belt? Dial it down. Want a quick burst for a robotic wheel? Turn it up. This flexibility doesn’t just make your motor adaptable; it also saves energy by avoiding unnecessary power use. For anyone asking how to control 12V DC motor speed easily, a speed controller is the straightforward, reliable fix.

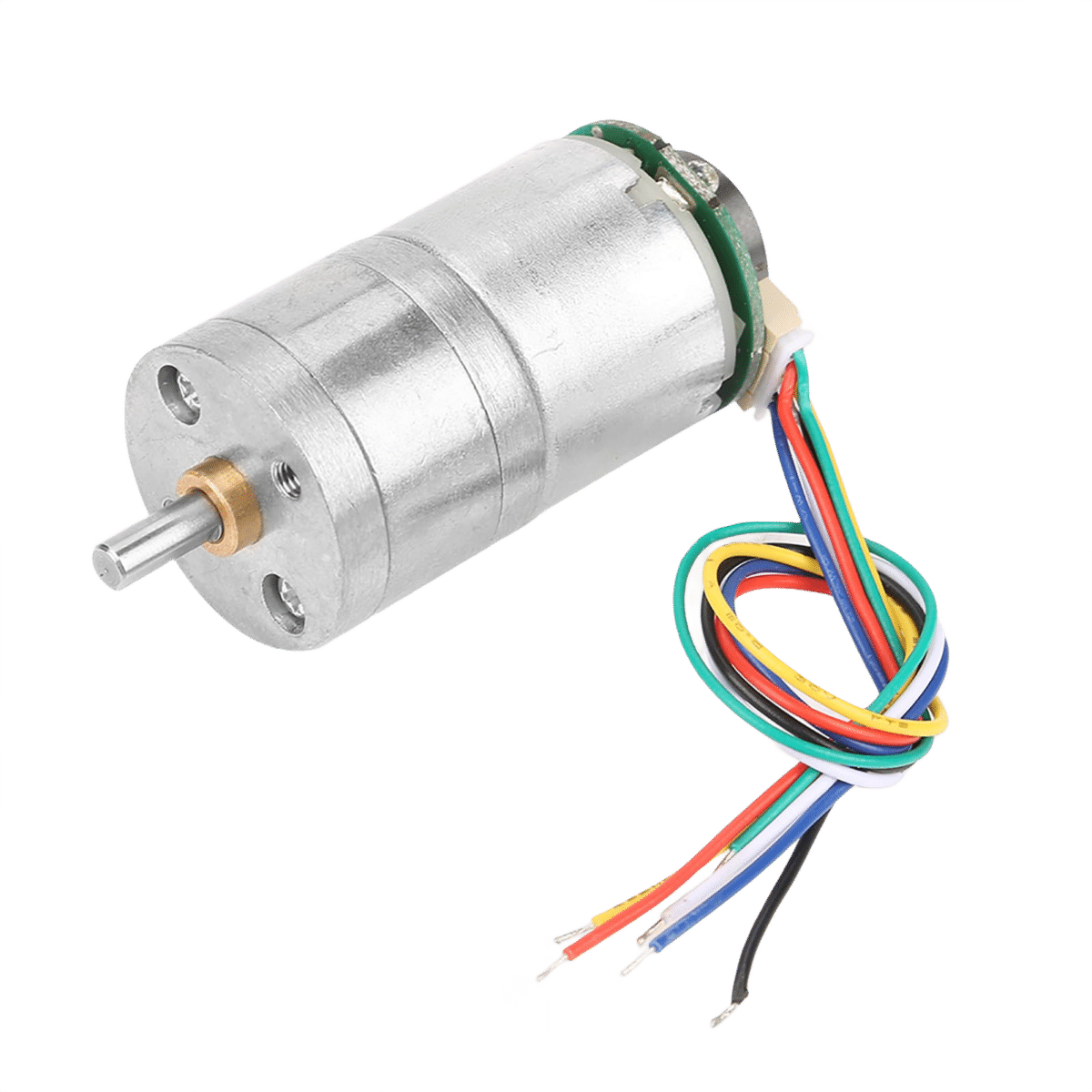

Adding Precision with a 12V DC Motor with Encoder

Now, bring in the encoder. A 12V DC motor with an encoder adds a layer of smarts by tracking position, speed, and direction in real-time. Think of it as a GPS for your motor: it tells your system exactly where the shaft is and how fast it’s moving. This is huge for tasks needing accuracy, like positioning a robotic arm or running a vending machine dispenser smoothly. Without an encoder, you’re guessing; with one, you’re in control. Pair it with a speed controller, and you’ve got a system that balances power and pinpoint accuracy.

Real-World Applications of 12V DC Motors with Accessories

The beauty of a 12V DC motor speed controller and a 12V DC motor with encoder isn’t just technical—it’s practical. These accessories turn basic motors into smart tools for all sorts of projects. From DIY builds to industrial setups, here’s how they shine in action.

Smart Robots and Autonomous Vehicles

Picture a small robot navigating your living room or a warehouse bot dodging obstacles. These machines need precise movement, and that’s where a 12V DC motor with encoder comes in. The encoder tracks wheel turns, feeding data back so the robot knows its position. Meanwhile, the 12V DC motor speed controller adjusts the pace—slowing for tight spots or speeding up on open stretches. Take a smart vacuum cleaner: it dodges furniture efficiently thanks to speed control and encoder feedback. For robotics fans or pros building autonomous vehicles, this setup is essential.

Precision Machinery in Industry

Beyond robots, precision machinery thrives with this duo. Consider medical devices like infusion pumps, where consistent dosing is critical. A 12V DC motor speed controller keeps the pump steady, while the encoder ensures every rotation is exact, cutting errors to nearly zero. Or think of a vending machine: when you pick a snack, the motor dispenses it smoothly without jamming, thanks to encoder precision and controlled speed. These 12V DC motor encoder applications show how small upgrades deliver big reliability, especially in high-stakes environments.

Choosing the Right Speed Controller and Encoder for Your 12V DC Motor

Convinced a 12V DC motor speed controller and 12V DC motor with encoder are worth it? Awesome—but picking the right ones matters. Compatibility and customization are key to making it work. Here’s a simple guide to get you started.

Compatibility Checklist

Start with the basics: fit. Your 12V DC motor speed controller must handle 12 volts without overheating or underperforming. Check the current rating too—if your motor draws more amps than the controller can manage, you’ll run into trouble. For encoders, confirm the interface: does it use digital signals (like quadrature) or analog? Ensure your control system—say, an Arduino or PLC—can read it. Lastly, think size. A bulky controller won’t cut it in a tight robot chassis. Get these right, and you’ll master how to control 12V DC motor speed with precision.

Why Customization Matters

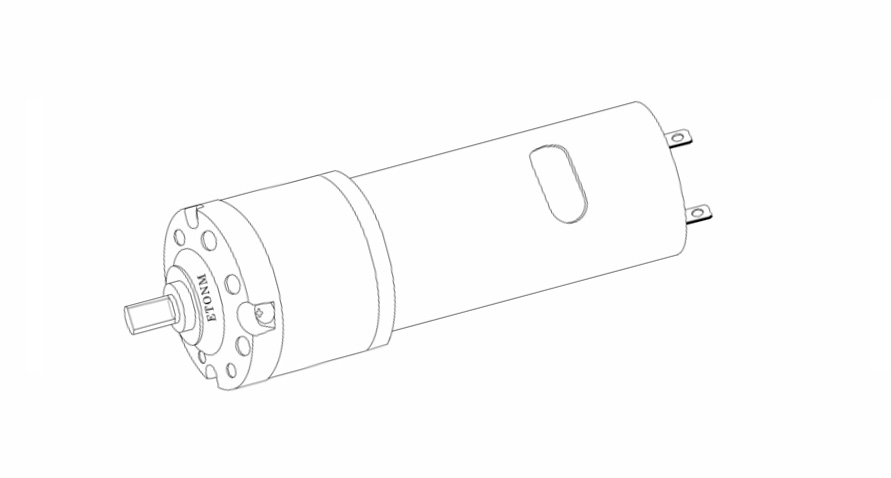

Off-the-shelf parts work for simple jobs, but what if your project’s unique? Maybe you need a smart dispenser with a specific RPM range or a robotic arm with ultra-precise positioning. That’s where custom solutions—like Etonm Motor’s—shine. A tailored 12V DC motor with encoder can match your exact load and speed needs, while a custom speed controller might add reverse functionality or overload protection. Curious? Check out Etonm’s planetary gear motor page for motors built to spec. Customization turns a good setup into the best speed controller for 12V DC motor performance.

Conclusion: Elevate Your Projects with Etonm Motor’s Custom Solutions

It’s clear now: a 12V DC motor speed controller and 12V DC motor with encoder aren’t just extras—they’re your ticket to precision and efficiency. Whether you’re tweaking a smart robot, powering a medical device, or dreaming up something new, this pairing gives you the control to make it happen. Speed controllers set the pace, encoders keep it on track, and together, they transform your motor into a smart solution.

At Etonm Motor, we know every project’s unique. That’s why we offer custom 12V DC motor solutions designed for your specific needs—be it a precise speed range, a compact build, or industrial durability. Ready to level up? Explore our micro DC motors or contact us to discuss your project. With the right tools and a touch of customization, your 12V DC motor can do amazing things. Let’s make it real!

Explore Our 12v DC Motors

Related Reading

- 12V DC Motor High Torque High RPM: Torque vs. Speed

- 12V DC Motor Shaft Design: Impact & Options

- 12V DC Motor Speed Controllers: How They Work & Setup Tips

- 12V DC Motor with Encoder: Precision Guide for Beginners

- How to Choose the Right Mini DC Motor Voltage

- How Does a DC Motor Work? A Simple Guide by Etonm Motor

- How to Reduce DC Motor Noise: Practical Tips from Etonm Motor

- Optimizing Brushless DC Motor Performance: The Role of Winding Configurations

- Exploring Performance Traits of Brushless DC Motors

- What is Electronic Speed Control (ESC) for Brushless DC Motors?

- How to Increase Torque in Brushless DC Motors: A Practical Guide

- 12V DC Motor High Torque Low RPM Performance

- Technical Parameters and Customization of Low RPM Brushless Motors: A Comprehensive Guide

- DC Speed Controller 12V Basics: From Brushed To BLDC

- 12V Low Speed High Torque Motor: Ideal For DIY Projects