Table of Contents

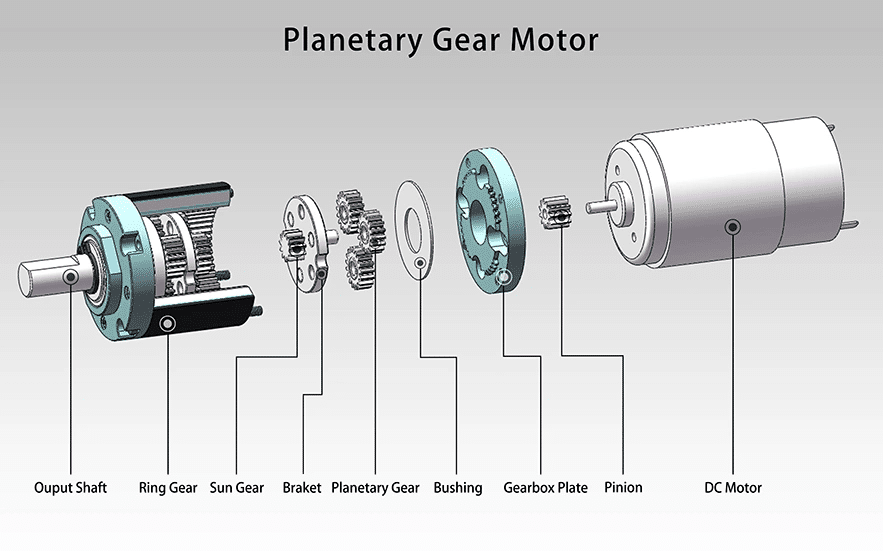

What is Planetary Gear Motor?

A planetary gear motor is a commonly used reducer, which consists of the planet gear, sun gear, and outer ring gear. The sun gear is usually placed in the center, and the planet gears orbit around the sun gear, receiving torque from it. The outer ring gear (refers to the lower housing) meshes with the planet gears.

How a Planetary Gear Motor Works?

- Stages: the number of sets of planetary gears. As one set of planetary gears cannot meet the larger drive ratio, sometimes 2 or 3 sets are needed to meet the user’s requirement of a larger drive ratio. Since the number of planetary gears is increased, the length of the 2-stage or 3-stage reducer will be increased and the efficiency will be reduced.

- Return clearance: When the output end is fixed and the input end is rotated clockwise and counterclockwise to produce the rated torque +-2% torque at the input end, there is a small angular displacement at the input end of the reducer, and this angular displacement is the return clearance.

- The planetary gear reducer consists of an inner gear ring tightly bonded to the gearbox shell, and a sun gear driven by external power in the center of the ring teeth, between which there is a set of three gears equally combined on a pallet of planetary gears The set of planetary gears is supported by the output shaft, inner gear ring and sun gears floating in the period; when the power on the incoming side drives the sun gear, it can drive the planetary When the incoming power drives the sun gear, it drives the planetary gears to rotate and follow the track of the inner ring to rotate along the center, and the planetary rotation drives the power output from the output shaft connected to the pallet.

Advantages of Planetary Gear Motors

- High torque: With more teeth in contact, the mechanism can transmit and withstand greater torque in a more uniform manner.

- Durable and efficient: The bearing can reduce friction by connecting the shaft directly to the gearbox. It allows for better rolling and smooth running, simultaneously enhancing efficiency.

- Easy to install: Its mechanism, contained in a cylindrical gearbox, can be installed in almost any space.

- Impressive precision: The rotation angle is fixed, which improves the accuracy and stability of the rotation movement.

- Compact size: The planetary gear motor can be compact and small due to the planetary structure, in which multiple gears mesh together and orbit around a sun gear. This achieves a 3.4mm, 4mm, or 6mm planetary gear motor.

- Low-noise: The multiple gears enable more surface contact. Rolling is much softer, and jumps are virtually nonexistent.

Parameters of ETONM's Planetary Gear Motors

| Outer Diameter | 3.4mm/22mm/24mm/28mm/32mm/36mm/42mm/56mm |

| Material | Precise Metal Gears |

| Output Torque Range | 0.05kg.cm~200kg.cm |

| Gear Ratio Range | 3.4-3736 |

| Output Speed Range | 1-2000rpm |

Related Reading

- What Is A Planetary Gear Motor? Structure, Working Principle & Benefits

- 12V DC Motor High Torque Low RPM Performance

- Introduction of Planetary Gear Motor for Robot

- Product Introduction: Low-Noise Gear Motors

- Introduction of 12V DC Micro Motor Products

- Why Choose 24v Small DC Motors?

- How to Choose the Right Planetary Gear Motor for Your Application

Our Planetary Gear Motors

Explore our wide range of Planetary Gear Motor Models, designed to meet diverse application needs. Whether you require high torque DC gear motors for industrial automation or compact planetary gear motors for robotics, our fully customizable solutions ensure optimal performance. Each motor is engineered with precision and can be tailored to specific voltage, gear ratio, and size requirements, making them ideal for robotics, medical devices, and beyond.

- Size(WL):Φ16mm

- Voltage:3-12VDC

- Speed:10-2000rpm

- Torque:0.05-5kg.cm

- Typical use:Safe and Locking、Electric Curtain、Electric Valve

- Size(WL):Φ16mm

- Voltage:6-12VDC

- Speed:10-2000rpm

- Torque:0.05-5kg.cm

- Typical use:Electric curtain/Blinds

- Size(WL):Φ22mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-8kg.cm

- Typical use: Electric Curtain/Blinds、Safe and Locking、Office Automation

- Size(WL):Φ22mm

- Voltage:3-12VDC

- Speed:1-2000rpm

- Torque:0.1-6kg.cmrpm

- Typical use: Electric Curtain、Safe and Locking、Office & Home Automation

- Size(WL):Φ22mm

- Voltage:3-24VDC

- Speed:1-2000rpm

- Torque:0.1-6kg.cm

- Typical use: Office & Home Automation、Equipment and Apparatus、Actuator

- Size(WL):Φ22mm

- Voltage:6-12VDC

- Speed:1-1500rpm

- Torque:0.1-8kg.cm

- Typical use: Electric curtain/Blinds、Antenna

- Size(WL):Φ24mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-8kg.cm

- Typical use: Electric curtain/Blinds、Antenna

- Size(WL):Φ28mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cm

- Typical use: Electric curtain、Actuator and Electric Valve、Office & Home Automation

- Size(WL):Φ32mm

- Voltage:12-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cm

- Typical use: Electric curtain、Actuator and Electric Valve、Coffee Bean Grinder and Coffee Maker

- Size(WL):Φ32mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cmrpm

- Typical use: Home and Office Automation、Equipment and Apparatus、Coffee Machine

- Size(WL):Φ36mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-60kg.cm

- Typical use: Robotics、Pump and Electric Valve、Banking and Medical Equipment

- Size(WL):Φ36mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cm

- Typical use: Home and Office Automation、Equipment and Apparatus、Pump

- Size(WL):Φ42mm

- Voltage:12-24VDC

- Speed:1-1000rpm

- Torque:0.1-80kg.cm

- Typical use: Apparatus and Equipments、Actuator and Robotics、Conveyor Roller

- Size(WL):Φ56mm

- Voltage:12-24VDC

- Speed:1-200rpm

- Torque:10-200kg.cm

- Typical use: Home and Office Automation、Equipment and Apparatus、Medical Device

- Size(WL):Φ32mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cm

- Typical use: Home and Office Automation、Equipment and Apparatus、Electric Oift

- Size(WL):Φ42mm

- Voltage:12-12VDC

- Speed:1-200rpm

- Torque:10-200kg.cm

- Typical use:Home and Office Automation、Equipment and Apparatus、Medical Device