Discover why Brushless DC Motors (BLDC Motors) are revolutionizing electric vehicles. Learn about their benefits, types, and why they are the preferred choice for modern EVs.

Table of Contents

Introduction

The automotive industry is undergoing a massive transformation, with electric vehicles (EVs) leading the charge toward a greener future. At the heart of this revolution lies advanced motor technology, and Brushless DC Motors (BLDC Motors) are playing a pivotal role in shaping the next generation of EVs.

Unlike traditional brushed motors, BLDC Motors offer superior efficiency, durability, and performance, making them the go-to choice for modern electric vehicles. Whether it’s powering the drivetrain, enhancing energy recovery systems, or ensuring smooth operation of auxiliary components, BLDC Motors are proving to be indispensable in the EV ecosystem.

In this guide, we’ll explore why BLDC Motors are the preferred option for electric vehicles, their key advantages, and how they’re driving innovation in the automotive sector. If you’re curious about the future of EV technology, you’re in the right place. Let’s dive in!

What Are BLDC Motors?

When it comes to electric vehicles, the motor is the unsung hero that keeps everything running smoothly. But what exactly makes Brushless DC Motors (BLDC Motors) so special? Let’s break it down.

Unlike traditional brushed motors, which rely on physical brushes for commutation, BLDC Motors use electronic controllers to manage power distribution. This design eliminates the need for brushes, reducing friction, wear, and maintenance. The result? A motor that’s not only more efficient but also lasts significantly longer.

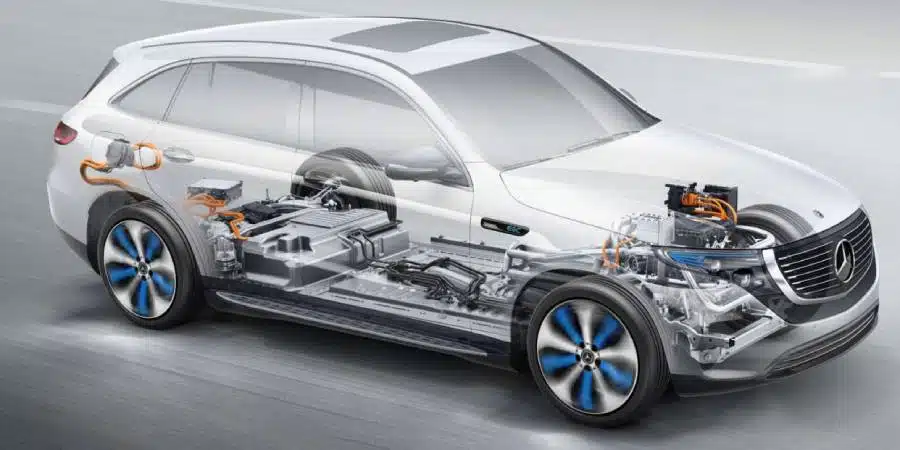

At their core, BLDC Motors consists of three main components: a stator, a rotor, and an electronic controller. The stator houses the windings, while the rotor contains permanent magnets. The controller, often powered by advanced algorithms, ensures precise control over speed and torque. This combination makes BLDC Motors ideal for applications where reliability and performance are critical—like in electric vehicles.

In short, BLDC Motors is a game-changer. They’re quieter, more efficient, and better suited for the demands of modern EVs than their brushed counterparts. But why are they so widely adopted in the automotive industry? Let’s explore that next.

Why BLDC Motors Are Used in Electric Vehicles

Electric vehicles are all about efficiency, performance, and sustainability—and Brushless DC Motors (BLDC Motors) deliver on all three fronts. But what makes them the top choice for EV manufacturers? Let’s take a closer look.

1. Higher Efficiency and Energy Savings

One of the biggest advantages of BLDC Motors is their exceptional efficiency. Unlike brushed motors, which lose energy due to friction and heat, BLDC Motors operate with minimal energy waste. This translates to longer driving ranges for electric vehicles, a critical factor for consumers. In fact, studies show that BLDC Motors can achieve efficiency levels of up to 90-95%, compared to 75-80% for brushed motors.

2. Durability and Low Maintenance

Another reason BLDC Motors are favored in EVs is their durability. Without brushes that wear out over time, these motors require far less maintenance. This is especially important for electric vehicles, which are designed for long-term reliability. Fewer maintenance intervals mean lower costs for owners and fewer disruptions to their daily lives.

3. Compact Design for Automotive Applications

Space is at a premium in electric vehicles, and BLDC Motors excel in this area. Their compact and lightweight design makes them perfect for integration into tight spaces, whether it’s the powertrain, HVAC system, or even regenerative braking mechanisms. This versatility allows automakers to optimize vehicle design without compromising performance.

In summary, BLDC Motors are a natural fit for electric vehicles because they offer unmatched efficiency, durability, and adaptability. But how do they stack up against other motor types? That’s what we’ll explore next.

Types of Motors Used in Electric Vehicles

When it comes to powering electric vehicles, not all motors are created equal. While Brushless DC Motors (BLDC Motors) are a popular choice, they’re not the only option available. Let’s compare BLDC Motors with other common motor types used in EVs to understand why they often come out on top.

1. Induction Motors

Induction motors, also known as asynchronous motors, have been widely used in electric vehicles, notably by Tesla in their earlier models. These motors are known for their robustness and ability to handle high power levels. However, they tend to be less efficient than BLDC Motors, especially at lower speeds. Additionally, induction motors are typically bulkier and heavier, which can impact the overall design and performance of an EV.

2. Permanent Magnet Synchronous Motors (PMSMs)

Permanent Magnet Synchronous Motors (PMSMs) are another common choice for EVs. Like BLDC Motors, they use permanent magnets in the rotor, which contributes to their high efficiency and power density. However, PMSMs often require more complex control systems and can be more expensive to produce due to the use of rare-earth magnets. In contrast, BLDC Motors strike a balance between performance, cost, and ease of control, making them a more versatile option for many EV applications.

3. Brushed DC Motors

Brushed DC motors, while simple and cost-effective, are rarely used in modern electric vehicles. Their reliance on brushes for commutation leads to higher maintenance requirements and lower efficiency compared to BLDC Motors. For EVs, where reliability and energy efficiency are paramount, brushed motors simply don’t cut.

Why BLDC Motors Stand Out

When compared to other motor types, BLDC Motors offers a unique combination of efficiency, durability, and compactness. They excel in applications where precise control, low maintenance, and high performance are essential—qualities that are critical for electric vehicles.

As we’ve seen, while there are several motor options for EVs, BLDC Motors consistently emerges as a top contender. But how are they being used in electric vehicles today? Let’s dive into their real-world applications next.

Applications of BLDC Motors in EVs

Brushless DC Motors (BLDC Motors) aren’t just theoretical marvels—they’re hard at work in some of the most critical systems of modern electric vehicles. From powering the wheels to enhancing energy recovery, BLDC Motors are integral to the performance and efficiency of EVs. Let’s explore their key applications.

1. Powertrain Systems

The powertrain is the heart of any electric vehicle, and BLDC Motors are often at its core. Their high efficiency and precise control make them ideal for driving the wheels, ensuring smooth acceleration and optimal energy usage. Unlike traditional motors, BLDC Motors can deliver consistent torque across a wide range of speeds, which is essential for the dynamic demands of driving.

2. HVAC Systems

Comfort is a top priority for EV drivers, and BLDC Motors play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. Their compact size and quiet operation make them perfect for powering fans and compressors, ensuring efficient climate control without draining the vehicle’s battery.

3. Regenerative Braking

One of the standout features of electric vehicles is regenerative braking, which recovers energy during deceleration and feeds it back into the battery. BLDC Motors are often used in these systems due to their ability to switch seamlessly between motor and generator modes. This not only improves energy efficiency but also extends the vehicle’s range.

4. Auxiliary Systems

Beyond the major systems, BLDC Motors are also found in various auxiliary components, such as power windows, windshield wipers, and even steering mechanisms. Their reliability and low maintenance requirements make them a practical choice for these smaller yet essential functions.

In short, BLDC Motors are everywhere in electric vehicles, quietly powering the innovations that make EVs smarter, greener, and more efficient. But as with any technology, there are challenges to overcome. Let’s take a closer look at what the future holds for BLDC Motors in the EV industry.

Challenges and Future Trends

While Brushless DC Motors (BLDC Motors) have become a cornerstone of electric vehicle technology, they’re not without their challenges. From cost considerations to technical complexities, there are hurdles to overcome. But with every challenge comes opportunity, and the future of BLDC Motors in EVs looks brighter than ever. Let’s explore both sides of the coin.

Current Challenges

Cost and Material Constraints

One of the primary challenges with BLDC Motors is their cost. The use of rare-earth magnets, such as neodymium, can drive up production expenses. Additionally, the electronic controllers required for BLDC Motors add to the overall cost, making them more expensive than traditional brushed motors.Control Complexity

BLDC Motors rely on sophisticated control systems to manage their operation. While this allows for precise speed and torque control, it also increases the complexity of design and implementation. Automakers must invest in advanced software and skilled engineers to fully leverage the potential of BLDC Motors.Thermal Management

High-performance applications, such as EV powertrains, can generate significant heat. Effective thermal management is crucial to prevent overheating and ensure the longevity of BLDC Motors. This often requires additional cooling systems, which can add weight and complexity to the vehicle.

Future Trends and Innovations

Advancements in Magnet Technology

Researchers are exploring alternatives to rare-earth magnets, such as ferrite magnets and advanced composite materials. These innovations could reduce costs and make BLDC Motors more accessible for mass-market EVs.Integration with AI and IoT

The future of BLDC Motors lies in smarter control systems. By integrating artificial intelligence (AI) and the Internet of Things (IoT), automakers can optimize motor performance in real-time, improving efficiency and adapting to driving conditions.Modular and Scalable Designs

As the demand for electric vehicles grows, so does the need for flexible motor solutions. Modular BLDC Motors that can be easily scaled or adapted for different vehicle types are likely to become a key trend, enabling faster development and customization.Sustainability and Recycling

With a growing focus on sustainability, the EV industry is exploring ways to make BLDC Motors more eco-friendly. This includes developing recyclable materials and improving manufacturing processes to reduce waste.

In conclusion, while challenges remain, the future of BLDC Motors in electric vehicles is full of promise. As technology continues to evolve, these motors will play an even greater role in shaping the next generation of sustainable transportation.

Conclusion

The rise of electric vehicles has ushered in a new era of automotive innovation, and Brushless DC Motors (BLDC Motors) are at the forefront of this transformation. From their unmatched efficiency and durability to their compact design and versatility, BLDC Motors have proven to be a game-changer for the EV industry.

Throughout this guide, we’ve explored why BLDC Motors are the preferred choice for electric vehicles, how they compare to other motor types, and their wide-ranging applications in powertrains, HVAC systems, regenerative braking, and more. We’ve also discussed the challenges they face, such as cost and control complexity, and looked ahead to exciting trends like AI integration and sustainable manufacturing.

As the demand for electric vehicles continues to grow, BLDC Motors will remain a critical component in driving the future of transportation. Their ability to deliver high performance while meeting the evolving needs of automakers and consumers makes them an indispensable part of the EV ecosystem.

If you’re looking for reliable, high-quality BLDC Motors for your electric vehicle projects, Etonm Motor is here to help. With years of expertise in custom motor solutions, we’re committed to delivering products that meet your unique requirements. Visit our website to learn more about our offerings or contact us today to discuss how we can support your next innovation.

Innovative Motor Solutions for Diverse Applications

ETONM MOTOR’s Mini DC Motors and Gear Motors are designed to meet the needs of a wide range of industries. Our motors provide reliable performance and precision across numerous applications, helping businesses power their projects with efficiency and innovation.