Learn how to troubleshoot common issues with BLDC Worm Gear Motors, including brushless worm gear motor problems, high torque failures, and more. Discover practical solutions to keep your motors running smoothly.

Table of Contents

Introduction to BLDC Worm Gear Motors and Their Importance

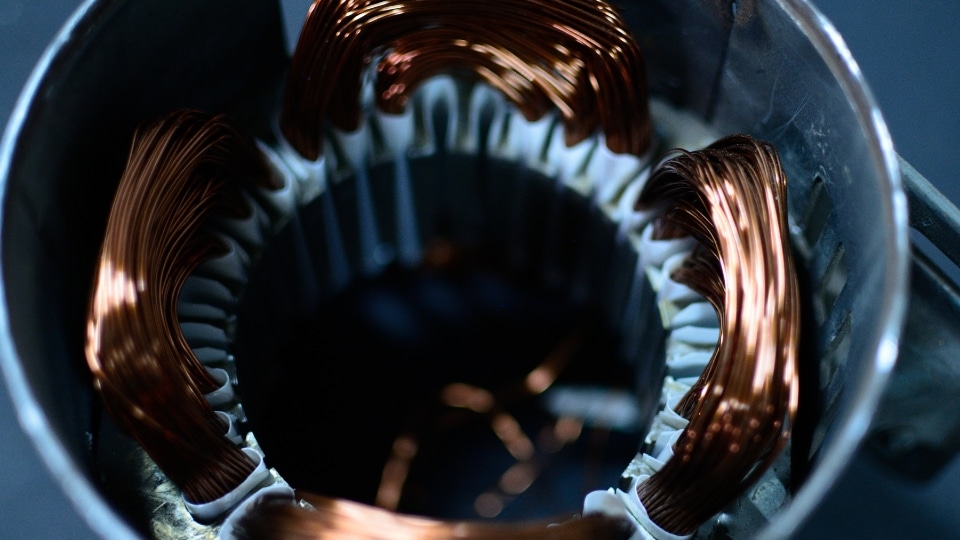

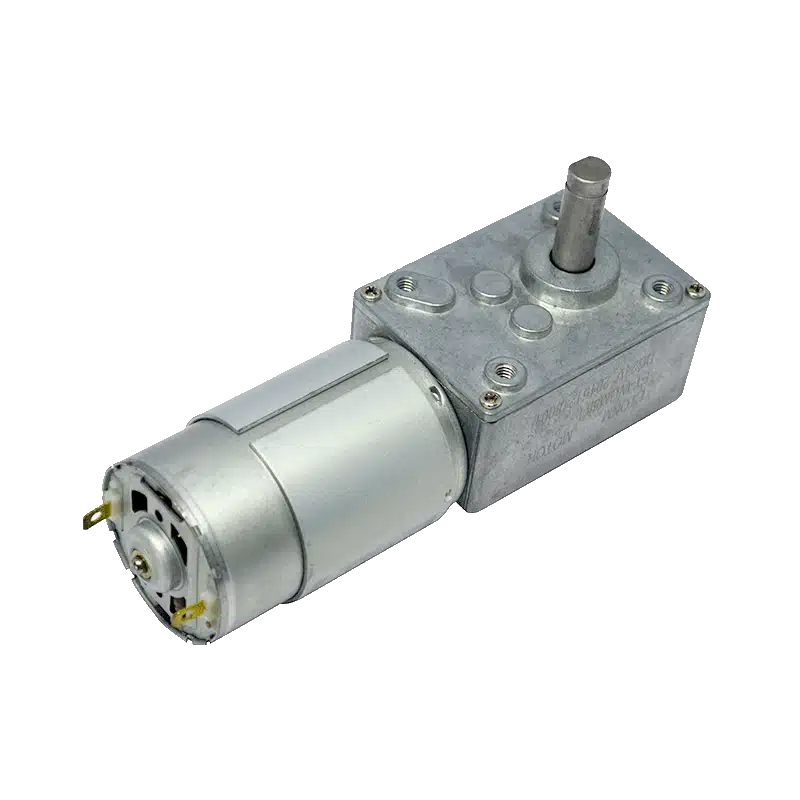

BLDC Worm Gear Motors, or Brushless DC Worm Gear Motors, is a cornerstone of modern precision engineering. These compact yet powerful motors combine the efficiency of brushless technology with the reliability of worm gear mechanisms, making them ideal for applications requiring high torque and smooth operation. From smart home devices to medical equipment, BLDC Worm Gear Motors ensures seamless performance.

However, these motors can encounter issues over time like any mechanical system. Whether it’s unusual noise, overheating, or a drop in performance, troubleshooting is essential to maintain their efficiency and extend their lifespan. In this guide, we’ll explore common problems with BLDC Worm Gear Motors—such as those found in 24V BLDC Gear motors or brushless worm gear motors—and provide practical solutions to keep them running at their best.

By understanding how to diagnose and fix these issues, you can save time, reduce downtime, and ensure your equipment operates reliably. Let’s dive into the world of BLDC Worm Gear Motor troubleshooting and uncover the steps to keep your systems in top shape.

Common Issues with BLDC Worm Gear Motors

Even the most reliable BLDC Worm Gear Motors can face challenges over time. Understanding these common issues is the first step toward effective troubleshooting. Below, we’ll break down the most frequent problems and their potential causes, helping you identify and address them quickly.

Why Do BLDC Worm Gear Motors Fail?

BLDC Worm Gear Motors are known for their durability, but they’re not immune to wear and tear. Some of the most common reasons for failure include:

- Overheating: Excessive load or poor ventilation can cause the motor to overheat, leading to reduced efficiency or even permanent damage.

- Unusual Noise or Vibration: Misaligned gears, worn-out components, or insufficient lubrication often result in noisy operation.

- Reduced Torque: A drop in torque output can stem from issues like voltage fluctuations (especially in BLDC Gear motor 24v systems) or internal gear damage.

By recognizing these symptoms early, you can take proactive steps to prevent further damage and ensure your brushless worm gear motor continues to perform optimally.

Overheating and Thermal Issues

Overheating is one of the most common problems in BLDC Worm Gear Motors, particularly in high-torque applications. Here’s what you need to know:

Causes:

Running the motor beyond its rated load capacity.

Inadequate cooling or ventilation in the system.

Incorrect voltage supply (e.g., using a 24V motor with a 12V power source).

Solutions:

Ensure the motor operates within its specified load and voltage range.

Improve airflow around the motor or consider adding a cooling fan.

Regularly check for signs of overheating, such as discoloration or a burning smell.

Addressing thermal issues promptly can significantly extend the lifespan of your BLDC motor with gearbox.

Unusual Noise and Vibration

If your worm gear electric motor is making strange noises or vibrating excessively, it’s a clear sign that something’s wrong. Here’s how to diagnose and fix the problem:

Causes:

Misalignment between the motor and gearbox.

Worn-out gears or bearings due to prolonged use.

Lack of proper lubrication in the gear mechanism.

Solutions:

Inspect the alignment of the motor and gearbox, adjusting if necessary.

Replace worn-out components, such as gears or bearings, with high-quality parts.

Regularly lubricate the gearbox to ensure smooth operation.

By tackling noise and vibration issues early, you can prevent further damage and maintain the efficiency of your high torque brushless motor.

Troubleshooting Steps for BLDC Worm Gear Motors

When your BLDC Worm Gear Motor starts acting up, a systematic approach to troubleshooting can save you time and money. Below, we’ll walk you through a step-by-step guide to diagnose and resolve common issues, ensuring your motor returns to optimal performance.

Step-by-Step Troubleshooting Guide

Troubleshooting a BLDC Worm Gear Motor involves checking various components and systems to pinpoint the root cause of the problem. Follow these steps to identify and fix issues effectively.

Check Power Supply and Voltage

One of the first things to inspect is the power supply, as incorrect voltage can lead to motor failure or poor performance.

Steps:

Use a multimeter to measure the voltage supplied to the motor.

Ensure the voltage matches the motor’s specifications (e.g., BLDC Gear motor 24v should receive 24V).

Check for fluctuations or drops in voltage, which could indicate a problem with the power source or wiring.

Solutions:

Replace or repair faulty power supplies or cables.

Use a voltage stabilizer if fluctuations are frequent.

Proper voltage supply is critical for the smooth operation of your DC brushless worm gear motor.

Inspect Gearbox and Lubrication

The gearbox is a crucial component of a BLDC Worm Gear Motor, and its condition directly impacts performance.

Steps:

Open the gearbox housing and visually inspect the gears for wear, cracks, or damage.

Check the lubrication level and quality—insufficient or degraded lubricant can cause friction and noise.

Listen for unusual sounds during operation, which may indicate misalignment or gear issues.

Solutions:

Replace damaged gears with high-quality replacements.

Clean the gearbox and apply the recommended lubricant.

Ensure the gearbox is properly aligned with the motor shaft.

Regular maintenance of the gearbox can prevent many issues in your BLDC motor with gearbox.

Test Motor Control Settings

The motor’s control system, including the driver and settings, plays a significant role in its performance.

Steps:

Verify that the motor driver is functioning correctly and providing the required current.

Check the control settings, such as PWM (Pulse Width Modulation) frequency and duty cycle, to ensure they match the motor’s requirements.

Look for error codes or warnings on the driver’s display (if available).

Solutions:

Adjust the control settings to match the motor’s specifications.

Replace or repair the motor driver if it’s faulty.

Consult the motor’s technical manual for specific control parameters.

Proper control settings are essential for optimizing the performance of your brushless worm gear motor.

Preventive Maintenance Tips for BLDC Worm Gear Motors

Preventive maintenance is the key to ensuring the long-term reliability and performance of your BLDC Worm Gear Motors. By taking proactive steps, you can minimize downtime, reduce repair costs, and extend the lifespan of your motors. Here are some essential maintenance tips to keep your BLDC Worm Gear Motors running smoothly.

How to Extend the Life of Your BLDC Worm Gear Motor

Regular maintenance not only prevents unexpected failures but also optimizes the efficiency of your BLDC Worm Gear Motors. Follow these best practices to keep your motors in top condition.

Regular Inspections and Cleaning

Routine inspections can help you identify potential issues before they escalate into major problems.

- Steps:

- Schedule periodic inspections of the motor and gearbox, especially in high-stress applications like high torque brushless motor systems.

- Check for signs of wear, such as cracks, corrosion, or loose components.

- Clean the motor housing and gearbox to remove dust, debris, or contaminants that could affect performance.

- Benefits:

- Early detection of issues reduces the risk of sudden failures.

- Clean components operate more efficiently and generate less heat.

Regular cleaning and inspections are simple yet effective ways to maintain your worm gear electric motor.

Proper Lubrication of the Gearbox

Lubrication is critical for the smooth operation of the gearbox in a BLDC Worm Gear Motor.

- Steps:

- Use the manufacturer-recommended lubricant for your specific motor model.

- Apply lubricant at regular intervals, especially in high-duty-cycle applications.

- Monitor the condition of the lubricant—replace it if it becomes contaminated or degraded.

- Benefits:

- Proper lubrication reduces friction, noise, and wear on gears.

- It ensures consistent torque output and extends the life of the gearbox.

A well-lubricated gearbox is essential for the reliable performance of your BLDC motor with gearbox.

Monitor Operating Conditions

The environment in which your BLDC Worm Gear Motor operates can significantly impact its performance and lifespan.

- Steps:

- Ensure the motor operates within its specified temperature range to prevent overheating.

- Avoid exposing the motor to excessive moisture, dust, or corrosive substances.

- Use protective enclosures or coatings if the motor is used in harsh environments.

- Benefits:

- Controlled operating conditions reduce stress on the motor and its components.

- It minimizes the risk of environmental damage, such as rust or electrical shorts.

Monitoring and optimizing operating conditions can significantly enhance the durability of your brushless worm gear motor.

Keep Spare Parts on Hand

Having critical spare parts readily available can save you time and minimize downtime during repairs.

- Recommended Spare Parts:

- Gears and bearings for the gearbox.

- Motor brushes (if applicable) or driver components.

- Lubricants and seals.

- Benefits:

- Quick replacement of worn-out parts reduces downtime.

- It ensures your motor can be repaired promptly, even in urgent situations.

Keeping spare parts on hand is a smart strategy for maintaining your BLDC Gear motor 24v systems.

Conclusion

Troubleshooting and maintaining BLDC Worm Gear Motors may seem daunting at first, but with the right knowledge and tools, it becomes a manageable and rewarding task. By understanding common issues like overheating, noise, and reduced torque, and following a systematic troubleshooting approach, you can keep your motors running efficiently and extend their lifespan.

Preventive maintenance, such as regular inspections, proper lubrication, and monitoring operating conditions, plays a crucial role in ensuring the reliability of your BLDC Worm Gear Motors. Whether you’re working with BLDC Gear motor 24v systems or high torque brushless motors, these practices can save you time, reduce costs, and minimize downtime.

At Etonm Motor, we specialize in providing high-quality BLDC Worm Gear Motors tailored to your specific needs. If you’re facing persistent issues or need custom solutions, our team is here to help. Visit our product page to explore our range of brushless worm gear motors and BLDC motors with gearboxes, or contact us for expert advice.

Related Reading

- Why BLDC Motors Are the Future of Electric Vehicles: A Complete Guide

- BLDC Motor vs Brushed Motor: Which is Better for Your Needs?

- The Ultimate Guide to Brushless DC Motors: Types, Applications, and Benefits

- What is a Worm Gear Motor? The Ultimate Guide to Its Applications and Benefits

- 12V DC Motor High Torque Low RPM Performance

- How to Maintain Gear Motors

- What Is A BLDC Worm Gear Motor? Uses, Benefits, And Applications

- How BLDC Worm Gear Motors Work?