Confused about DC motor parameters? Learn key factors like torque, speed, and armature resistance to pick the right motor for your project with Etonm Motor.

Table of Contents

Introduction

Ever wondered why one DC motor outperforms another in your latest project? Maybe you’re tinkering with a robotic arm, setting up a smart home gadget, or even designing a vending machine that doesn’t jam halfway through dispensing a snack. Whatever the case, it all boils down to understanding DC motor parameters. These little specs are the secret sauce behind how motors turn electrical juice into mechanical magic—and they’re what separates a smooth-running system from a frustrating flop.

DC motors are everywhere, quietly powering stuff like sanitary dispensers, electric valves, and even medical devices. But here’s the catch: not every motor is built the same. That’s why knowing the key parameters—like torque, speed, and armature resistance—can save you headaches (and maybe a few bucks) down the road. In this guide, we’re breaking it all down in plain English, so you can figure out what matters most for your next big idea. Stick around, and we’ll walk you through the must-know details to make choosing a DC motor feel less like a guessing game. Let’s dive in!

Why DC Motor Parameters Matter

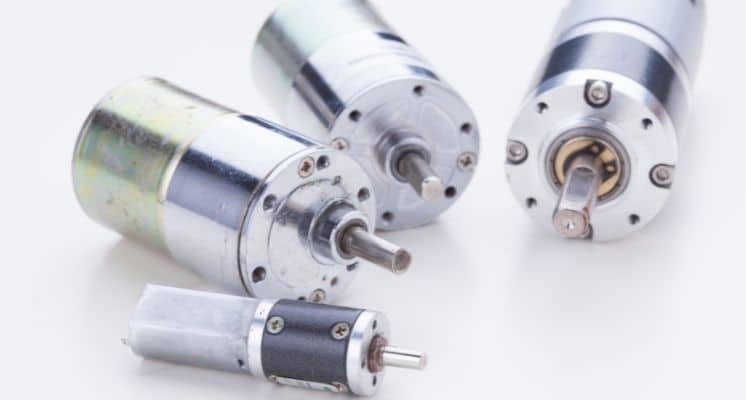

So, why should you care about DC motor parameters? It’s not just nerdy trivia for engineers—it’s the difference between a motor that nails the job and one that leaves you scratching your head. Think about it: if you’re building a robotic arm for precision tasks, a motor with weak torque might stutter under load. Or if you’re rigging up a smart home device, like a curtain opener, a motor with sloppy speed control could turn your sleek setup into a jerky mess. These parameters aren’t abstract—they directly shape how your motor performs in the real world.

Take applications like security systems or vending machines, for example. A motor with high friction torque might burn out faster from constant use, while one with optimized armature resistance keeps humming along without overheating. At Etonm Motor, we’ve seen firsthand how dialing in these specs can make or break a project. That’s why we customize solutions for everything from medical care tools to sanitary dispensers—because picking the right motor isn’t one-size-fits-all. Want to know how to choose a DC motor that fits your needs? It starts with understanding what these numbers mean for your specific gig. Let’s unpack the big ones next.

Key Parameters of DC Motors Explained

Now that you see why these specs aren’t just fluff, let’s dig into the nitty-gritty of DC motor parameters. These are the heavy hitters that decide if your motor’s up to the task—or if it’s going to leave you high and dry. Don’t worry, we’ll keep it simple and skip the jargon overload.

1. Torque – The Muscle Behind the Motion

Torque is the raw twisting power a motor cranks out, measured in N.m or kg.m. Picture it like the push you need to get a stubborn jar lid off—starting torque is that initial shove, while running torque keeps things spinning smoothly. If you’re moving heavy loads, like in robotics or industrial valves, you’ll want a motor with solid starting torque to kick things off without a hitch. Understanding DC motor torque is key because it tells you how much muscle you’ve got to work with. Too little, and your project stalls; too much, and you’re overpaying for power you don’t need.

2. Rotation Speed – How Fast Can It Go?

Next up is rotation speed, usually listed in RPM (revolutions per minute) or rad/s for the science buffs. This is how quick your motor spins—think of a 3000 RPM motor whirring away in a fan or a pump. But here’s the catch: the “no-load speed” is what it hits without anything dragging it down, and that drops once you add weight or resistance. The mechanical time constant ties in here too—it’s how long it takes to hit 63.2% of that top speed from a dead stop. DC motor rotation speed explained like this makes it easier to match a motor to your project, whether it’s a zippy dispenser or a steady medical device.

3. Armature Resistance – The Heat Factor

Armature resistance might sound boring, but it’s a big deal. It’s the internal resistance in the motor’s winding (plus brush contact in brushed motors), measured in ohms. When current flows, this resistance generates heat—less resistance means less heat and better efficiency. Think of it like a water hose: a narrow one slows the flow and heats up, while a wide one lets everything run cool. If energy savings or long runtime matter to you, check this spec. Armature resistance in DC motors is one of those sneaky factors that can quietly tank performance if ignored.

4. Bonus Parameters to Watch

There’s more to the story, too. The torque coefficient shows how much twist you get per ampere of current—handy for fine-tuning power. Friction torque is the drag from brushes and bearings eating into your efficiency, and the electrical time constant (inductance divided by resistance) tells you how fast the current stabilizes. These are like the fine print on a contract—nice to know, but not always dealbreakers. Still, key parameters of DC motors like these can tip the scales when you’re picking between two close contenders.

There you have it—the core lineup that makes DC motors tick. Up next, we’ll tie it all together so you can pick the right one without breaking a sweat.

How These Parameters Help You Choose the Right Motor

Alright, you’ve got the rundown on torque, speed, and resistance—now what? These DC motor parameters aren’t just fun facts to toss around at the next engineering meetup; they’re your cheat sheet for picking a motor that actually works for your project. Whether you’re tweaking a smart home gadget or building a robot that doesn’t flop over, here’s how to put this info to use.

Let’s break it down with a quick checklist. Need to lift something heavy, like in a vending machine drop mechanism? Prioritize starting torque—it’s the kick that gets the job done. Tight on power, say for a battery-powered medical device? Look at armature resistance; a lower value keeps the heat down and the efficiency up. If speed’s your game—like a fast-spinning mixer in a sanitary dispenser—match the rotation speed (RPM) to your target, and double-check the mechanical time constant to avoid laggy startups. It’s less about memorizing numbers and more about lining up what your project demands with what the motor delivers.

Not sure where to start? Peek at Etonm Motor’s Micro DC Motor catalog—we’ve got options galore, from brushless to planetary gear motors, all spec’d out for easy picking. Want a pro tip? Cross-check efficiency stats from a solid source like MIT’s motor design guide to see how these parameters play out in real designs. It’s like having a roadmap—suddenly, choosing a DC motor feels less like a stab in the dark and more like a calculated win. Ready to wrap this up? Let’s hit the highlights one last time.

Conclusion

So, there you have it—torque, rotation speed, and armature resistance are your starting line for picking a DC motor that won’t let you down. These parameters aren’t just specs on a sheet; they’re the backbone of how your motor will perform, whether it’s powering a robotic arm or keeping a smart home device humming. I’ve seen too many projects stall out because someone grabbed the first motor they found—don’t let that be you! A little know-how here goes a long way.

Feeling ready to make a move? Swing by Etonm Motor’s lineup to explore options tailored for everything from security systems to medical tools. Need something custom? Contact us—we’re all about finding the perfect fit for your next big thing. Go get that project spinning!

Related Reading

- 12V DC Motor High Torque Low RPM Performance

- How to Calculate Transmission Gear Ratio: A Comprehensive Guide for Gear Systems

- What Factors Affect the Performance of Brushless Motors? A Comprehensive Guide

- Why Use a DC Motor Controller for BLDC Motor?

- How to Increase Torque in Brushless DC Motors: A Practical Guide

- What is Electronic Speed Control (ESC) for Brushless DC Motors?

- Exploring Performance Traits of Brushless DC Motors

- What Is DC Motor Torque? A Simple Guide by Etonm Motor

- How Temperature Rise Affects Motor Performance and Lifespan

- Comparison of Commutation Methods in Brushless DC Motors: Sensor vs. Sensorless

- Optimizing Brushless DC Motor Performance: The Role of Winding Configurations

- How to Reduce DC Motor Noise: Practical Tips from Etonm Motor

- What Determines the Speed of a Brushless DC Motor?

- Technical Parameters and Customization of Low RPM Brushless Motors: A Comprehensive Guide

- Comprehensive Guide to Low-Noise Gear Motors: Features, Types, and Applications