"Explore the essentials of controlling 12V motors with DC speed controllers. Learn how brushed and BLDC motor controllers work, their applications, and why Etonm Motor stands out in precision solutions."

Table of Contents

Introduction

Controlling the speed of a 12V DC motor is a critical aspect of many applications, directly impacting performance and reliability. Whether it’s for automating smart home devices, powering robotic systems, or operating vending machines, precise speed management ensures optimal functionality. A DC speed controller 12V provides an effective solution for adjusting motor performance, offering options for both brushed and brushless motors, including the advanced BLDC motor controller 12V.

Effective speed control enhances efficiency, extends motor lifespan, and ensures the system meets specific operational needs. Running a motor too fast can lead to overheating, while insufficient speed may reduce productivity. This article explores the fundamentals of 12V motor speed control, detailing how controllers function for brushed and brushless motors and their practical applications. With years of experience, Etonm Motor offers tailored solutions to support a wide range of projects, from industrial equipment to innovative designs.

Understanding DC Speed Controllers for Brushed Motors

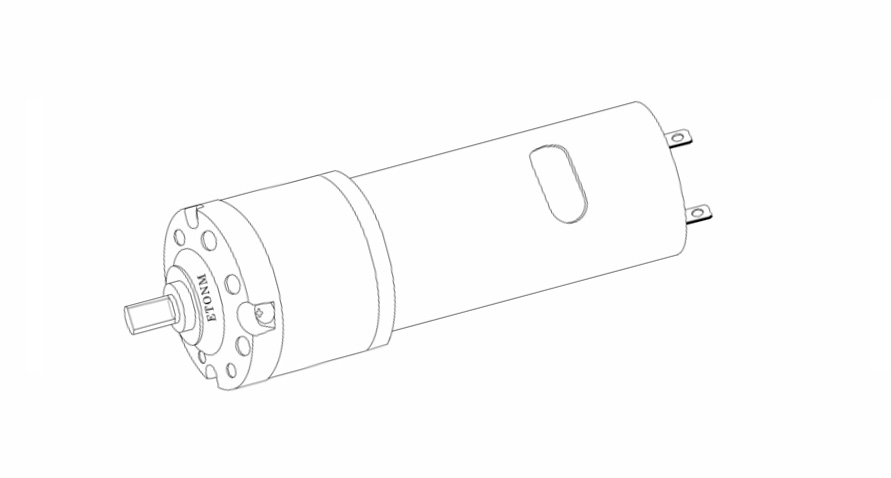

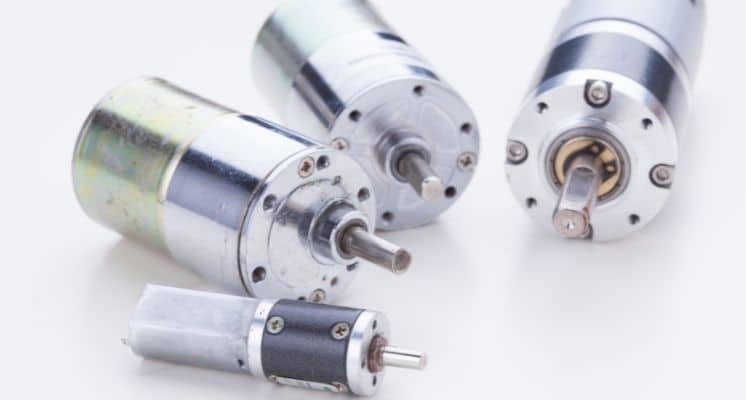

Brushed motors remain a popular choice for 12V applications due to their straightforward design and cost-effectiveness. When paired with a DC speed controller 12V, they provide reliable performance across various uses, from small-scale projects to industrial equipment. This section explains their operation and benefits.

How a DC Speed Controller 12V Works

A DC speed controller for brushed motors regulates power delivery to adjust rotational speed. Most controllers employ Pulse Width Modulation (PWM), a method that adjusts voltage by rapidly switching the power supply on and off. This allows precise control over the motor’s speed, enabling it to operate anywhere from 0 to 100% of its capacity—typically between 50W and 150W, depending on the motor’s specifications.

This approach is practical and efficient for brushed motors, making it suitable for applications where high precision is not the primary concern. The controller’s ability to vary speed ensures consistent performance without requiring complex configurations.

Benefits for Everyday Applications

DC speed controllers for brushed motors are widely used in practical settings. In smart homes, a DC speed controller 12V can regulate motorized curtain tracks, ensuring smooth and efficient operation. Similarly, sanitary dispensers rely on these controllers to deliver consistent amounts of soap or sanitizer, while vending machines use them to position products accurately for dispensing.

Their versatility stems from ease of use and affordability. At Etonm Motor, we’ve seen these controllers applied in diverse scenarios, including electric valves and basic robotics, demonstrating their value in cost-sensitive projects. For more details on compatible motors, visit our Micro DC Motor page.

Precision Control with BLDC Motor Controllers

While brushed motors cover basic needs, brushless DC (BLDC) motors offer advanced capabilities, requiring specialized control. A BLDC motor controller 12V provides the precision and efficiency demanded by complex applications. This section outlines their unique features and uses.

What Makes BLDC Motor Controller 12V Different?

BLDC motors operate without physical brushes, relying instead on electronic commutation managed by a BLDC motor controller 12V. This controller sends targeted signals to adjust speed and torque, reducing friction and heat compared to brushed motors. As a result, BLDC systems offer greater durability and lower maintenance needs.

The electronic control enables smoother speed adjustments and higher efficiency, with BLDC motors often achieving over 85% efficiency, compared to 75% or less for brushed motors. This makes them ideal for applications where energy conservation and precise operation are priorities.

Real-World Uses of BLDC Controllers

BLDC motor controllers excel in high-performance environments. In drones, a BLDC motor controller 12V adjusts motor speeds rapidly to maintain stability and responsiveness during flight. In robotics, these controllers ensure accurate movements for tasks like assembly or navigation, where consistency is essential.

Medical equipment, such as infusion pumps or portable ventilators, also benefits from BLDC controllers, leveraging their quiet operation and reliability. Etonm Motor designs BLDC solutions for these critical applications, combining power and precision. Learn more on our Brushless Motor page.

Choosing the Right Controller for Your Project

Selecting an appropriate controller for a 12V motor requires aligning its features with your project’s requirements. Both DC speed controller 12V and BLDC motor controller 12V options offer distinct advantages, and understanding their differences helps ensure optimal results.

Factors to Consider When Picking a Controller

Start by evaluating the motor’s load. A 50W motor for a smart home device has different demands than a 200W motor for an industrial pump. For lighter loads, a DC speed controller for brushed motors is often sufficient, offering ease of installation and affordability. For heavier loads or precision needs, a BLDC motor controller provides superior efficiency and control.

Efficiency is another key factor. Brushed motor controllers may lose some energy to heat, suitable for short-term use, while BLDC controllers minimize waste, benefiting continuous or battery-powered operations. Speed range is also critical—most 12V controllers support 0 to 100% adjustment, but BLDC systems deliver smoother transitions for nuanced applications.

Matching Controllers to Your Application

The controller should suit the application’s purpose. For vending machines or electric valves, a brushed motor with a DC speed controller 12V offers dependable performance at a lower cost. In contrast, robotics or medical devices demand a BLDC motor controller 12V for its precision and longevity.

Power ratings provide guidance—a typical 12V motor ranges from 50W to 200W. Match the controller’s capacity to your motor’s current requirements to avoid overheating. Etonm Motor’s experience shows that starting with your project goals simplifies the selection process. Explore options on our Micro DC Motor page.

Conclusion

Effective speed control is essential for 12V motor performance, with DC speed controller 12V options serving simpler applications and BLDC motor controller 12V solutions addressing advanced needs. Brushed controllers are ideal for cost-effective setups like vending machines, while BLDC controllers support high-precision tasks in robotics and drones.

Choosing the right controller depends on factors like load, efficiency, and application demands. Etonm Motor offers a variety of standard and custom solutions to meet these needs, ensuring reliability across industries. Contact us or explore our products today to find the right fit for your project.

Explore our 12v DC Motors

Related Reading

- Custom Control: Pairing 12V DC Motors with Speed and Encoder Accessories

- 12V DC Motor High Torque High RPM: Torque vs. Speed

- 12V DC Air Pump Motors: Small Size, Big Pressure

- 12V DC Motor Speed Controllers: How They Work & Setup Tips

- 12V DC Motor Guide: From Basics to Uses

- 12V DC Motor with Encoder: Precision Guide for Beginners

- Low RPM Brushless Motor: Technical Specs & Customization

- Mini DC Motor Selection Guide

- What Determines the Speed of a Brushless DC Motor?

- Exploring Performance Traits of Brushless DC Motors

- 12V Low Speed High Torque Motor: Ideal For DIY Projects