Curious about what makes Brushless DC Motors tick? Dive into their standout performance traits and see why they’re a game-changer for robotics, smart homes, and more.

Table of Contents

Introduction

Ever wondered why Brushless DC Motors are popping up everywhere—from the whirring robots in a factory to the smart gadgets in your home? These little powerhouses have become a favorite for engineers and designers, and it’s not hard to see why. They pack a punch with performance traits that make them reliable, efficient, and downright versatile. In this post, we’re diving into what makes these motors tick, exploring their standout characteristics, and showing you why they might just be the unsung heroes behind your favorite tech. Stick around—there’s plenty to unpack!

What Makes Brushless DC Motors Stand Out?

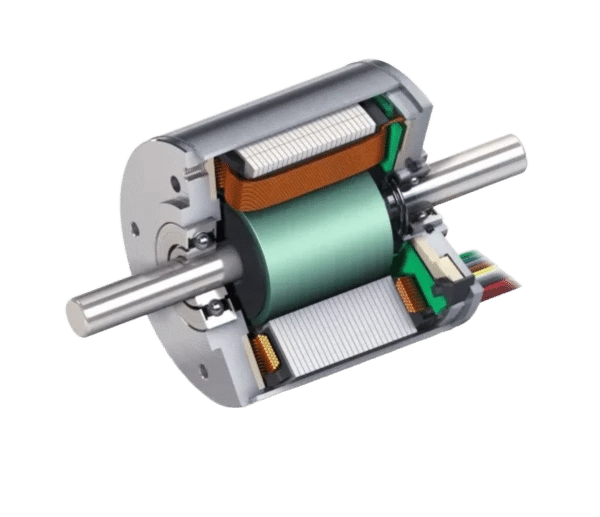

Let’s get one thing straight: Brushless DC Motors aren’t your average motors. Unlike their brushed counterparts, these guys ditch the physical brushes and rely on electronic commutation to keep things spinning. That small tweak makes a world of difference—less friction, fewer parts wearing out, and a whole lot more efficiency. If you’ve ever dealt with a brushed motor that sputtered out too soon, you’ll appreciate why low-maintenance motors like these are stealing the spotlight. So, what’s the secret sauce behind their performance? Let’s break it down and see why they’re a cut above the rest.

Key Performance Characteristics of Brushless DC Motors

Brushless DC Motors aren’t just a trendy choice—they deliver where it counts. Let’s unpack the traits that make them a go-to for everything from robotics to smart home gadgets.

1. High Efficiency That Saves Power

One of the biggest wins with Brushless DC Motors is their efficiency. Without brushes creating friction, they convert more electrical energy into motion—think 85-90% efficiency compared to 75% for brushed motors. That means less power wasted and longer runtime, which is why you’ll spot Brushless motor efficiency shining in battery-powered stuff like smart home sensors or handheld medical tools. It’s a small change with a big payoff.

2. Impressive Durability for Long-Term Use

Durability is where these motors really flex. No brushes mean fewer parts to wear down, so DC motor durability becomes a standout feature—perfect for robotics that need to keep humming 24/7. I’ve seen companies swap out brushed motors every year, only to switch to low maintenance motors like these and forget about replacements for ages. Less downtime, fewer headaches—it’s hard to argue with that.

3. High Torque and Speed Control

Need power and precision? Brushless DC Motors deliver high torque Brushless Motors that punch above their weight, paired with BLDC motor speed control that’s smooth as butter. That combo makes them ideal for tricky jobs like powering vending machine gears or tweaking electric valves on the fly. It’s not just brute strength—it’s smart strength, tailored to the task.

Real-World Applications of Brushless DC Motors

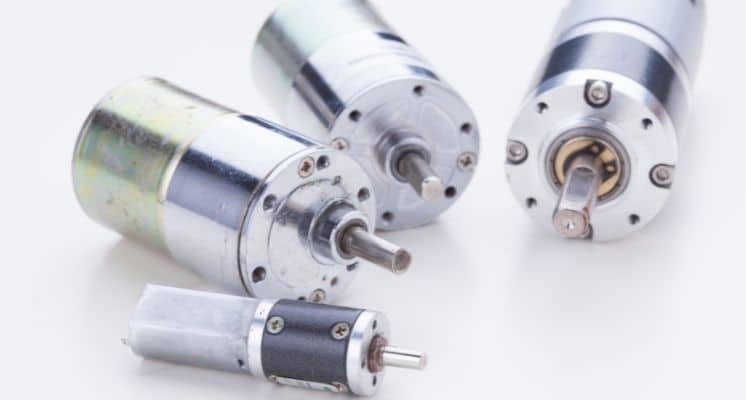

Brushless DC Motors aren’t just lab darlings—they’re out there doing the heavy lifting in everyday tech. From robotics to smart home devices, their versatility shines through. Take a sanitizer dispenser, for instance: a Brushless DC Motor keeps it running smoothly for years, with no fuss needed. That’s just one slice of the pie—Brushless DC Motor applications stretch across medical care (think precise pumps), vending machines (reliable coin slots), and even electric valves in water meters. Curious about how they fit into robotics? Check out our deep dive on that here for the full scoop. These motors are proof that small tech can make a big impact.

Are Brushless DC Motors Worth the Hype?

So, do Brushless DC Motors live up to all the buzz? On the plus side, they bring a lot to the table—top-notch efficiency, rock-solid durability, and flexibility that fits almost any project. Brushless motor efficiency alone can cut power costs over time, especially in high-use setups like robotics or smart home systems. For me, the reliability seals the deal; knowing a motor won’t quit mid-job is pure gold. That said, they’re not perfect—upfront costs can sting a bit more than brushed options. But when you factor in the long haul—fewer repairs, longer life—it’s hard to argue against them. Worth it? I’d say yes, if your budget can swing it.

Conclusion

Brushless DC Motors pack a serious punch—high efficiency, tank-like durability, and pinpoint control make them a standout choice for modern tech. Whether you’re tinkering with a robot or designing the next smart home must-have, these motors have your back. Want to dig deeper? Explore our guide on Micro DC Motors for more inspiration to kickstart your next project. Here’s to building something awesome!

Related Reading

- How Temperature Rise Affects Motor Performance and Lifespan

- Brushless DC Motors vs. Brushed DC Motors: Key Advantages

- What Is DC Motor Torque? A Simple Guide by Etonm Motor

- How to Choose a Suitable Brushed DC Motor for Your Project

- What Are the Key Advantages of Brushless Motors?

- How Does a Brushless DC Motor Work? A Complete Guide to BLDC Motors

- What is KV Rating in Brushless Motors and How to Calculate It?

- Why Use a DC Motor Controller for BLDC Motor?

- What Factors Affect the Performance of Brushless Motors? A Comprehensive Guide

- How to Calculate Transmission Gear Ratio: A Comprehensive Guide for Gear Systems

- Technical Parameters and Customization of Low RPM Brushless Motors: A Comprehensive Guide