“Robot motors are the unsung heroes of the robotics world, powering everything from simple toy robots to complex industrial machines. They are the driving force behind the movement, precision, and functionality that make robots so versatile and useful in our daily lives. Whether you're a robotics enthusiast, a student, or a professional, understanding the different types of robot motors and how to choose the right one for your application is crucial.”

Table of Contents

Introduction

Robot motors are the unsung heroes of the robotics world, powering everything from simple toy robots to complex industrial machines. They’re the driving force behind the movement, precision, and functionality that make robots so versatile and useful in our daily lives. Whether you’re a robotics enthusiast, a student, or a professional, understanding the different types of robot motors and how to choose the right one for your application is crucial.

In this comprehensive guide, we’ll dive into the world of robot motors, exploring their types, characteristics, and selection criteria. By the end, you’ll have the know-how to pick the perfect motor for your next project, whether it’s a hobby bot or a high-stakes automation system.

Understanding Robot Motors

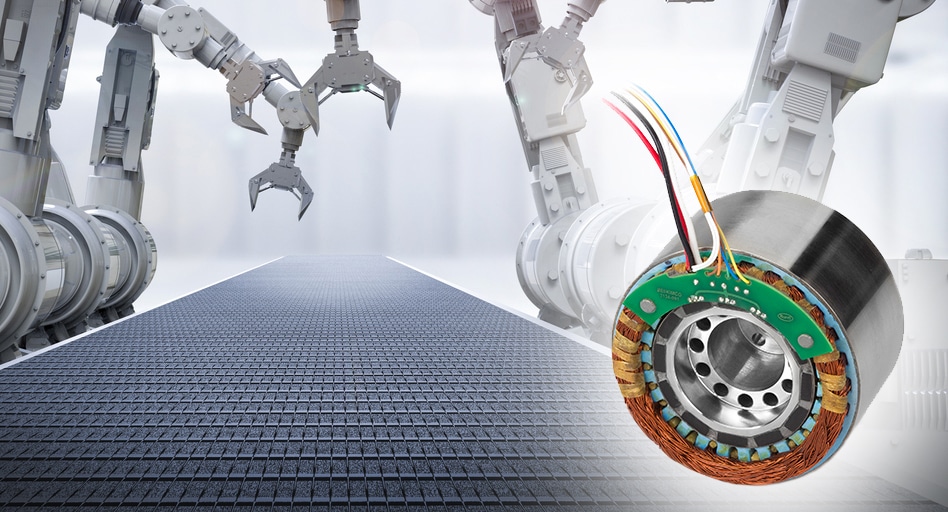

Robot motors are the heartbeat of any robotic system, turning electrical energy into the mechanical motion that brings robots to life. From a tiny bot zipping across your living room to a massive industrial arm lifting heavy parts, these motors make it happen. But not all robot motors are the same—each type has its own vibe, strengths, and quirks. Let’s break it down and meet the main players.

Types of Robot Motors

When it comes to robot motors, variety keeps things interesting. Here’s a rundown of the most common types you’ll run into:

- DC Motors: The reliable workhorses—simple, affordable, and easy to control. Great for basic movement like spinning wheels, though they need extras like encoders for precision.

- Stepper Motors: The detail-oriented ones. They move in exact steps, perfect for precise tasks like 3D printing, but they’re not built for speed.

- Brushless Motors: The sleek, modern option. No brushes mean higher efficiency and longer life, ideal for fast robots like drones—though they cost more and need complex controls.

- Gear Motors: These pair a motor with gears to boost torque over speed. A favorite for strength-focused bots, like those from Etonm Motor’s gear lineup.

Each type of robot motor has its own superpower, depending on what your project calls for—speed, accuracy, or raw power.

Gear Motors in Robotics

Gear motors are like the trusty pickup trucks of robotics—built for power, not speed. These clever devices team a standard motor with a gear system to crank up torque while keeping speed in check. That makes them a go-to for robots that need to lift, push, or pull heavy loads without breaking a sweat. Let’s dig into what makes them tick and why they’re a big deal in robotics.

What Are Gear Motors?

Gear motors are a power couple: a DC motor paired with a gearbox—think planetary, worm, or spur gears. The gears slow the output speed while pumping up the twisting power, or torque. This balance is spot-on for robotic tasks where strength beats speed. Etonm Motor crafts options like planetary gear motors for smooth precision and worm gear motors for compact toughness, tailored to robotic needs.

Benefits and Applications

Why go with gear motors in robotics? They deliver high torque in a small package, perfect for cramped spaces like robotic joints or grippers. They’re reliable and efficient too, keeping robots humming without constant fixes. You’ll see them powering factory robotic arms, rugged terrain rovers, or even vending machine gears. With gear motors, it’s all about muscle and finesse.

To learn more about gear motors, please read these articles:

- Micro and Mini Planetary Gear Motors: Power in Compact Design

- Planetary Gear Motor Explained: Benefits & Uses

- Advantages of Brushless Planetary Gear Motors

- Low-Noise Gear Motors: Quiet Power by Etonm Motor

- Gear Motor Applications: Top Uses Explored

- How to Choose a Gear Motor for Your Project

- What is a Planetary Gear Motor Used For?

- Gear Motor vs DC Motor vs Stepper Motor: Key Differences

- Helical Worm Gear Motor vs. Worm Gear Stepper Motor

- Spur Gear Motor vs. Worm Gear Motor: Which Is Best?

- Planetary Gear Motors vs. Spur Gear Motors: Which Wins?

- Gear Motor Types and Applications Explained

- How to Choose the Right Planetary Gear Motor for Your Application

- How to Choose the Right Brushless Gear Motor for Your Application

Brushless Motors for Robots

If gear motors are the dependable trucks, brushless motors are the flashy sports cars—fast, efficient, and built to impress. These high-tech gems skip the brushes of traditional motors, offering a smoother run with less upkeep. For robots that need to zip around or work long hours, brushless motors are tough to top. Let’s peek at what makes them special and why they’re a robotics favorite.

Advantages of Brushless Motors

Common Uses in Robotics

Where do brushless motors strut their stuff? Anywhere speed and stamina count. They’re buzzing in drones, where their light weight and high power keep things flying. You’ll also spot them in robotic vehicles zipping along or surgical robots needing smooth, reliable motion. Brushless motors for robots blend performance with durability—a winning combo in the field.

Learn more about brushless DC motors:

- What Are the Key Advantages of Brushless Motors?

- Brushless DC Motors: Key Uses in Smart Home, Medical & Robotics

- How to Increase Torque in Brushless DC Motors: A Practical Guide

- Why Brushless DC Motors Are a Game-Changer for Hair Dryers

- Power Up Precision: High-Speed Brushless DC Motors for Screwdrivers

- Brushless DC Motor vs. Servo Motor: What’s the Difference?

- Outrunner vs. Inrunner: Which Brushless DC Motor Fits Your Needs?

- How Brushless DC Motors Power the Digital World

- Exploring Brushless DC Motors and More in Electric Vehicles

- Why Brushless DC Motors Are Revolutionizing Power Tools

- How Brushless DC Motors Power Modern Household Appliances

- Exploring Performance Traits of Brushless DC Motors

- Brushless DC Motors vs. Brushed DC Motors: Key Advantages

- Comparison of Commutation Methods in Brushless DC Motors: Sensor vs. Sensorless

- What Determines the Speed of a Brushless DC Motor?

- Low RPM Brushless Motor: Technical Specs & Customization

- How to Choose the Right Brushless Motor for Your Drone: A Complete Guide

Choosing Between Gear and Brushless Motors

Picking the right robot motor is like choosing between a hammer and a scalpel—each shines in its own way, but the task decides the champ. Gear motors and brushless motors are robotics heavyweights, yet they serve different vibes. One’s about raw strength, the other’s all speed and finesse. Let’s stack them up and figure out what fits your robotic vision.

Gear Motors vs. Brushless Motors: A Quick Comparison

Gear motors rule when torque is the goal. They slow things down to ramp up twisting power, ideal for robots lifting heavy stuff or tackling rough terrain—think arms or rovers. Brushless motors, though, are speed champs. Lighter, more efficient, and low-maintenance, they’re perfect for fast bots like drones or precision tools. Gear motors win on cost, while brushless ones carry a premium for their tech edge.

How to Decide What’s Best for Your Robot

How do you choose the right robot motor? Start with your robot’s gig. Need to haul or push? Gear motors, like Etonm Motor’s planetary or worm picks, bring the brawn. Want speed or long runs? Brushless motors deliver. Size, budget, and control needs play in too—gear motors fit tight spots, while brushless ones need room for controllers. Match the motor to your robot’s soul and purpose.

Tips for Motor Selection and Integration

Choosing the right robot motor is just step one—getting it to vibe with your robot is the real adventure. Whether you’re crafting a speedy drone or a solid robotic arm, a few savvy tips can dodge future hassles. Here’s the lowdown on picking and integrating motors, straight from the robotics front lines.

Key Factors to Consider When Choosing a Motor

Start with the basics: what’s your robot doing? Torque and speed set the stage—gear motors like Etonm Motor’s planetary options crush heavy lifting, while brushless motors zip through fast jobs. Size counts; a chunky motor won’t suit a slim bot. Match power efficiency and voltage to your battery, and prioritize toughness—robots get roughed up. Dig into the spec sheet to find the best robot motors for your build.

Making Integration a Breeze

Got your motor? Now make it work. Pair it with a controller that clicks—brushless motors need ESCs, while gear motors might just want a basic driver. Toss in an encoder for precision; it’s like a robot’s extra sense. Test early, tweak gear ratios or settings to nail the sweet spot. Etonm Motor’s crew can help iron out wrinkles, ensuring your robot motor runs like a dream.

Conclusion

Robot motors are the backbone of any robotic system, fueling everything from playful hobby bots to hardcore industrial rigs. We’ve walked through their world—from torque-packed gear motors to zippy brushless wonders—and how to pick the best robot motors for your gig. Whether you’re chasing power, efficiency, or both, knowing your options is the secret sauce to a killer robot.

At Etonm Motor, we’ve got your back. Our lineup of planetary gear motors, worm gear motors, and brushless motors is ready for any robotic challenge. Want to kickstart your next project? Swing by our website or drop us a line—our team’s stoked to help you find the perfect robot motor and turn your ideas into reality.