Curious about gear motor types? From planetary to DC gear motors, learn how they power robotics, smart homes, and more with Etonm Motor’s expertise.

Table of Contents

Introduction

Ever wondered what keeps your smart blinds humming or powers that robot arm you saw in a YouTube video? Chances are, there’s a gear motor behind it. These little workhorses are everywhere—quietly driving the tech that makes our lives easier, from smart homes to medical gadgets. But here’s the thing: not all gear motors are created equal. They come in different types, each with its own superpower, whether it’s precision, power, or fitting into tight spaces. In this post, we’re breaking down the world of gear motor types—think planetary, DC, mini, and more—and showing you how they shine in real-world gear motor applications like robotics or your next vending machine snack run. At Etonm Motor, we’ve been crafting these solutions for years, so stick with us to find out which type might just be the perfect fit for your next project. Ready? Let’s dive in!

What Are Gear Motors and Why Do They Matter?

Before we get into the nitty-gritty of gear motor types, let’s take a step back and talk about what these things actually are. At its core, a gear motor is like the unsung hero of machinery—a combo of an electric motor and a gearbox working together to deliver just the right mix of speed and torque. Think of it as the muscle behind the movement, whether it’s opening a smart lock or spinning the wheels of a robotic vacuum. The gearbox part is key: it tweaks the motor’s raw power into something usable, like turning a fast spin into a slow, forceful push.

So why should you care? Because gear motors are everywhere! They’re the secret sauce in stuff we use daily—vending machines that drop your soda, sanitary dispensers keeping things clean, even medical devices that need pinpoint precision. Without them, a lot of modern tech would just… stop. And here’s the fun part: different jobs need different flavors of gear motors. That’s where the types come in—planetary for heavy lifting, DC for simple tasks, and so on. Stick around as we unpack the main gear motor applications and types next, so you can see why they’re such a big deal in everything from robotics to your smart home setup.

Exploring the Main Types of Gear Motors

Now that we’ve got the basics down, let’s roll up our sleeves and dig into the gear motor types you’re likely to come across. Each one’s got its own personality—some are tiny powerhouses, others are built for brute strength. Here’s the rundown, complete with where they shine in the real world.

1. Planetary Gear Motors

First up, the planetary gear motor—the overachiever of the bunch. These motors use a clever setup of gears orbiting around a central “sun” gear, packing a ton of torque into acompact package. They’re champs at handling heavy loads with smooth, precise motion. You’ll find them in gear motors for robotics, powering robot arms that need to move just right, or in electric valves where reliability is non-negotiable. I love how they’re like the Swiss Army knife of motors—small but mighty, and ready for almost anything.

12V Gear Motor, Mini Planetary Gearbox, Ball Valve Motor

2. DC Gear Motors

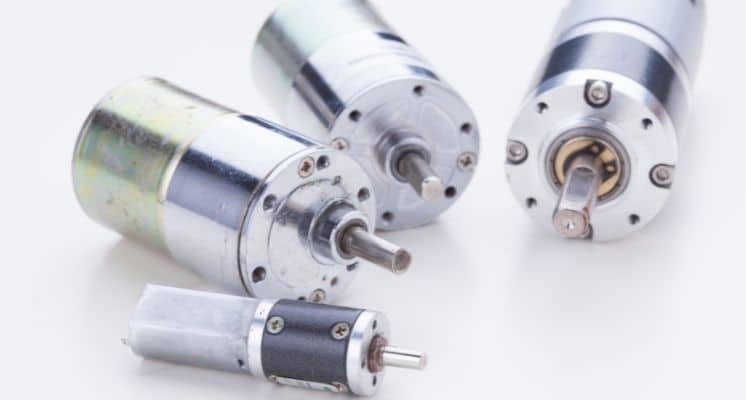

Next, we’ve got DC gear motors, the easygoing all-rounders. Powered by direct current, they’re straightforward and super versatile, making them a go-to for everyday stuff. Think smart home gadgets like motorized blinds or vending machines that spit out your snacks—they’re probably running on a DC gear motor. They’re not fussy, they’re affordable, and they get the job done. Your coffee dispenser at work? Yep, likely one of these behind the scenes.

3. Mini Gear Motors

Don’t let the name fool you—mini gear motors might be small, but they’re a big deal in tight spaces. These pint-sized heroes, often built with micro DC motors, are perfect for jobs where size matters more than raw power. Picture them in portable medical devices—like a handheld insulin pump—or tiny robotics projects buzzing around a lab. They’re proof that good things really do come in small packages.

4. Stepper Gear Motors

If precision’s your thing, say hello to stepper gear motors. These motors move in exact, controlled steps, making them ideal for anything needing spot-on positioning. Ever seen a 3D printer whip up a cool design? That’s a stepper gear motor at work. They’re also big in CNC machines, where every fraction of an inch counts. They’re like the perfectionists of the gear motor world—slow and steady wins the race.

5. Worm Gear Motors

Then there’s the worm gear motor, with its quirky worm-and-wheel design that’s all about high reduction ratios. That means it can turn fast motor speed into slow, powerful output—perfect for heavy-duty tasks. You’ll spot these in security systems, like gate openers, or sanitary dispensers that need a strong, steady push. They’re a bit niche, but when they fit the bill, nothing else quite matches up.

6. Large-Scale Gear Motors

Last but not least, large-scale gear motors are the heavy lifters. Built for big jobs, these beasts tackle industrial robotics or massive actuators that need serious muscle. Think factory floors where machines haul hefty loads all day long. They’re not subtle, but when you need power over finesse, they’re your guy.

There you have it—a lineup of gear motor types that cover everything from tiny tweaks to industrial grunts. Next up, we’ll see how these bad boys play out in real-world gear motor applications, so stick with me!

Gear Motors in Action: Real-World Applications

So, we’ve met the players—planetary, DC, mini, and the rest of the gear motor types. But where do they actually show up in the wild? Let’s take a spin through some gear motor applications that might surprise you—or at least make you nod and go, “Oh, that makes sense.” These motors aren’t just sitting in a lab; they’re out there powering stuff we use every day.

Start with robotics, where gear motors for robotics steal the spotlight. Planetary gear motors keep robot arms moving with precision—think of a factory bot welding car parts or a little rover exploring a classroom science project. Stepper gear motors chip in too, making sure every turn is exact, like in those robotic grippers picking up tiny screws. It’s pretty cool to see how these motors team up to bring sci-fi vibes to life.

Then there’s the smart home scene. Ever hit a button to lower your blinds or unlock your door with an app? That’s likely a DC gear motor doing the heavy lifting—quietly and reliably. They’re cheap, simple, and perfect for small jobs around the house. I’d bet most of us have a handful of these humming away without even noticing.

In medical care, mini gear motors are the unsung heroes. Picture a portable oxygen concentrator or a compact insulin pump—those tiny micro DC motors keep things running smoothly in devices that fit in your hand. They’re small enough to stay out of the way but tough enough to handle critical tasks. Honestly, it’s amazing how something so little can make such a big difference.

Oh, and here’s a neat stat: did you know over 60% of smart home devices rely on some kind of gear motor? That’s according to a report from Grand View Research, and it just shows how hooked we are on these things. From vending machines to security gates powered by worm gear motors, they’re woven into the fabric of modern life.

Want to see more examples? Check out our product catalog at Etonm Motor—everything from brushless options to heavy-duty large-scale gear motors for industrial gigs. Bottom line: wherever there’s motion, there’s probably a gear motor making it happen.

Click here to learn more about what our motors are used for or what industries we manufacture motors for.

Choosing the Right Gear Motor for Your Project

By now, you’ve got a solid rundown of gear motor types and where they pop up in the real world. But here’s the million-dollar question: how do you pick the right one for your gig? Whether you’re tinkering with a DIY robot or designing a smart home gadget, choosing the perfect motor doesn’t have to feel like rocket science. Let’s break it down with a few pointers that’ll steer you in the right direction.

First off, think about torque—how much muscle do you need? If you’re moving heavy loads, like in industrial robotics, a planetary gear motor is your best bet with its high-torque punch. On the flip side, if it’s a lighter job—say, spinning a small vending machine drum—a DC gear motor might do the trick without breaking the bank. Match the torque to the task, and you’re halfway there.

Next, consider size. Got a cramped space? A mini gear motor or micro DC motor can squeeze into tight spots—like in a portable medical device—while still packing enough oomph. But if space isn’t an issue and you’re going big, a large-scale gear motor can handle the heavy lifting without batting an eye.

Then there’s precision. Need exact movements, like in a 3D printer? A stepper gear motor is your guy—it moves in tiny, controlled steps so nothing’s off by even a hair. For less picky jobs, though, a worm gear motor might work fine, especially if you want slow, steady power over pinpoint accuracy.

Oh, and don’t sleep on power source and budget. DC motors are easy to power and wallet-friendly, while brushless gear motors (a fancier cousin) offer longer life but cost a bit more. Weigh what you can swing and what your project can’t live without.

Still scratching your head? Our Planetary Gear Motor page at Etonm Motor has specs and options to kickstart your search. The trick is to balance what you need—torque, size, precision—with what you’ve got to spend. Get that right, and your project’s golden.

Conclusion

So, there you have it—a crash course on gear motor types and how they power the world around us. From the torque-packed planetary gear motors ruling robotics to the trusty DC gear motors keeping your smart home ticking, each type brings something unique to the table. We’ve seen mini gear motors squeeze into medical devices, stepper gear motors nail precision in 3D printers, and even worm gear motors tackle heavy-duty security gigs. It’s wild how these little machines shape so much of what we do every day.

Picking the right one for your project? It’s all about matching torque, size, and precision to your needs—whether you’re building a robot or just tinkering for fun. At Etonm Motor, we’ve got a whole lineup of these motors waiting to bring your ideas to life. Not sure where to start? Swing by our product catalog to browse options, or drop us a line—we’d love to help you find the perfect fit. Here’s to powering up your next big thing!

Related Reading

- Advantages of Planetary Gear Motors

- What is a Worm Gear Motor? The Ultimate Guide to Its Applications and Benefits

- What is a Planetary Gear Motor?

- The Ultimate Guide to Brushless DC Motors: Types, Applications, and Benefits

- What is a BLDC Worm Gear Motor? A Comprehensive Guide for 2025

- How Do BLDC Worm Gear Motors Work? A Complete Guide

- How to Choose the Right Brushless Gear Motor for Your Application

- How to Choose the Right Planetary Gear Motor for Your Application

- What Is a Gear Motor? Benefits and Uses by Etonm Motor

- Planetary Gearbox Explained: How It Works

- Introduction of Planetary Gear Motor for Robot

- Comprehensive Guide to Low-Noise Gear Motors: Features, Types, and Applications

- How to Maintain Gear Motors