Discover how Brushless DC Motors (BLDC Motors) work, their advantages, and their applications in industries like robotics, smart home devices, and medical care.

Table of Contents

Introduction

Brushless DC Motors, commonly known as BLDC Motors or simply Brushless Motors, have revolutionized the world of mini and micro motor applications. Unlike traditional brushed motors, these advanced motors rely on electronic controllers instead of physical brushes for operation, making them more efficient, durable, and precise.

From smart home devices like automated locks and HVAC systems to medical equipment such as surgical tools and infusion pumps, Brushless DC Motors are at the heart of countless modern technologies. Their compact size, high performance, and energy efficiency make them ideal for applications where precision and reliability are critical.

In this article, we’ll dive into the inner workings of a Brushless DC Motor, explore its key components, and uncover why it’s the preferred choice for industries ranging from robotics to industrial automation. Whether you’re an engineer, a tech enthusiast, or simply curious about how these motors power your everyday devices, this guide will provide valuable insights into the fascinating world of BLDC Motors.

What is a Brushless DC Motor?

A Brushless DC Motor (BLDC Motor) is an advanced type of electric motor that operates without the brushes and commutators found in traditional brushed motors. Instead, it uses an electronic controller to manage the flow of current, ensuring smooth and efficient operation. This design eliminates the friction and wear caused by brushes, making BLDC Motors more reliable and longer-lasting.

The key difference between a Brushless Motor and a brushed motor lies in its commutation process. In brushed motors, physical brushes make contact with a commutator to switch the direction of current, which generates motion. In contrast, a BLDC Motor relies on electronic sensors (like Hall sensors) and a controller to precisely time the current flow to the motor’s coils. This not only improves efficiency but also allows for greater control over speed and torque.

Thanks to their brushless design, these motors are widely used in applications where precision, durability, and compact size are essential. From robotics and smart home devices to medical equipment and industrial automation, Brushless DC Motors have become a cornerstone of modern technology.

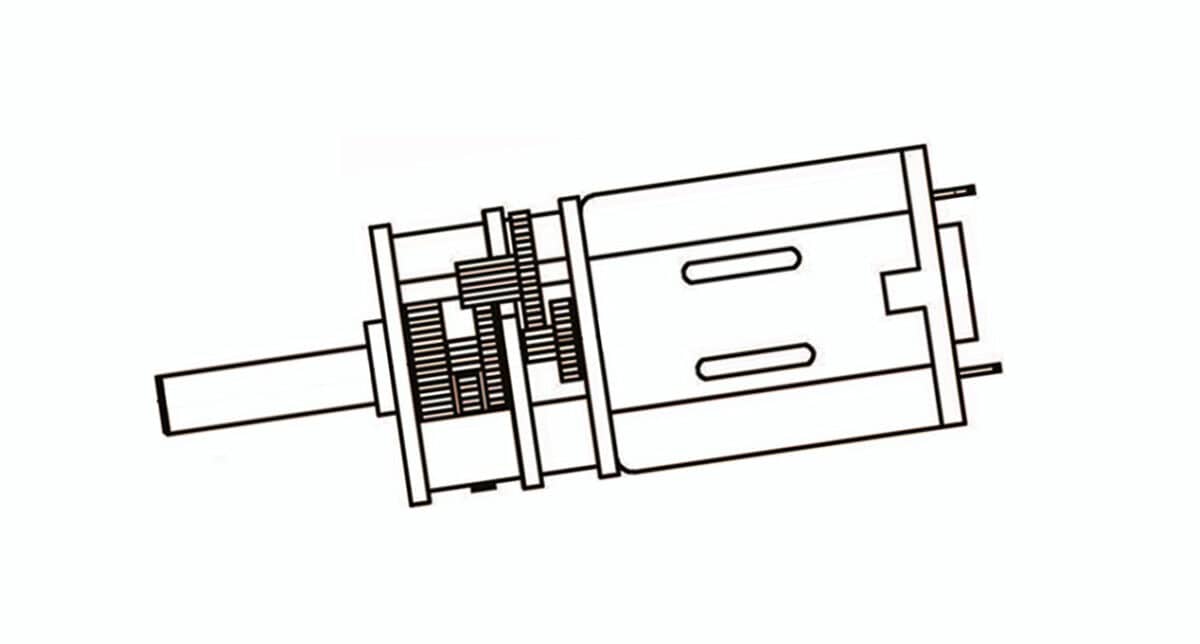

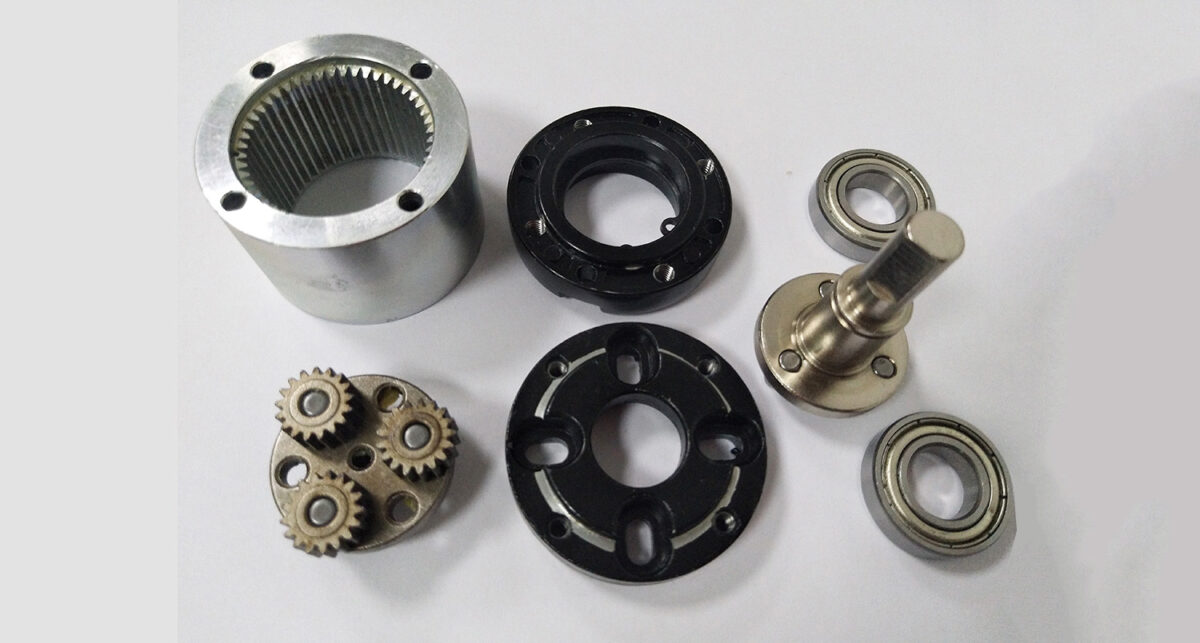

Key Components of a BLDC Motor

To understand how a Brushless DC Motor (BLDC Motor) works, it’s essential to break down its main components. Each part plays a critical role in ensuring the motor operates efficiently and reliably. Let’s take a closer look at the key elements:

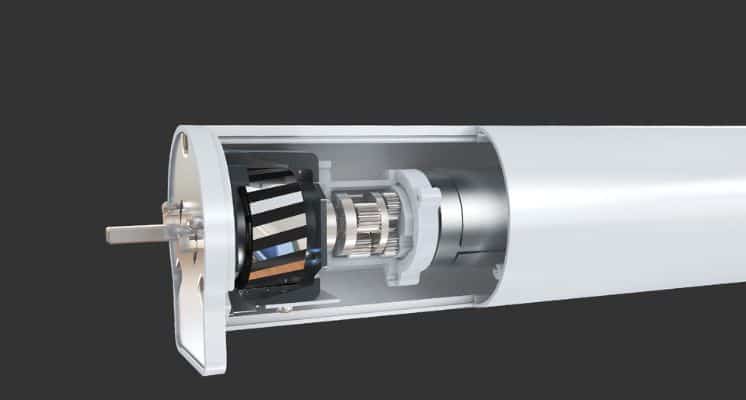

1. Stator

The stator is the stationary part of the motor and consists of multiple coils arranged in a specific pattern. When electric current flows through these coils, they generate a rotating magnetic field. This magnetic field interacts with the rotor to produce motion. The design of the stator is crucial for determining the motor’s performance, including its speed and torque.

2. Rotor

The rotor is the rotating part of the motor and is typically made up of permanent magnets. These magnets are arranged in a way that aligns with the stator’s magnetic field. As the stator’s magnetic field rotates, it pulls the rotor along, creating the motor’s rotational motion. The use of permanent magnets makes the rotor lightweight and highly efficient.

3. Hall Sensors

Hall sensors are small devices embedded in the motor to detect the position of the rotor. They send signals to the electronic controller, which uses this information to determine when to switch the current in the stator coils. This precise timing ensures smooth and efficient operation, making BLDC Motors ideal for applications requiring high accuracy.

4. Electronic Controller

The electronic controller is the brain of the Brushless DC Motor. It manages the flow of current to the stator coils based on input from the Hall sensors. By controlling the timing and sequence of current flow, the controller ensures the motor operates at the desired speed and torque. This level of control is what sets BLDC Motors apart from their brushed counterparts.

Together, these components work in harmony to deliver the high performance, efficiency, and reliability that make Brushless DC Motors a top choice for industries like robotics, smart home devices, and medical care.

How Does a Brushless DC Motor Work?

The operation of a Brushless DC Motor (BLDC Motor) is based on the principles of electromagnetic induction and electronic commutation. Unlike brushed motors, which rely on physical brushes to switch the direction of current, a BLDC Motor uses an electronic controller to manage the flow of electricity. Here’s a step-by-step breakdown of how it works:

1. Generating a Rotating Magnetic Field

When power is supplied to the motor, the electronic controller sends current to the stator coils in a specific sequence. This creates a rotating magnetic field around the stator. The speed and direction of this field depend on the timing and order of the current flow.

2. Interaction Between Stator and Rotor

The rotor, which is equipped with permanent magnets, aligns itself with the stator’s rotating magnetic field. As the field moves, it pulls the rotor along, causing it to rotate. This interaction is what generates the motor’s motion.

3. Role of Hall Sensors

Hall sensors play a crucial role in ensuring smooth operation. They detect the position of the rotor and send this information to the electronic controller. Based on the rotor’s position, the controller adjusts the current flow to the stator coils, maintaining the rotation of the magnetic field and, consequently, the rotor.

4. Electronic Commutation

The electronic controller continuously monitors and adjusts the current flow to the stator coils. This process, known as electronic commutation, replaces the mechanical commutation used in brushed motors. By eliminating physical brushes, BLDC Motors reduce friction, wear, and energy loss, resulting in higher efficiency and longer lifespan.

5. Advantages Over Brushed Motors

Compared to traditional brushed motors, Brushless DC Motors offer several advantages:

Higher Efficiency: No brushes mean less energy loss due to friction.

Greater Precision: Electronic control allows for precise speed and torque adjustments.

Reduced Maintenance: The absence of brushes minimizes wear and tear, reducing the need for frequent maintenance.

In summary, the combination of a rotating magnetic field, precise electronic control, and advanced components like Hall sensors makes BLDC Motors a superior choice for applications requiring high performance and reliability.

Advantages of BLDC Motors

Brushless DC Motors (BLDC Motors) have become a preferred choice across various industries due to their numerous advantages over traditional brushed motors. Here are the key benefits that make BLDC Motors stand out:

1. Higher Efficiency

One of the most significant advantages of BLDC Motors is their high efficiency. Since they don’t rely on brushes for commutation, there’s minimal energy loss due to friction. This makes them ideal for applications where energy conservation is critical, such as in smart home devices and electric vehicles.

2. Longer Lifespan

The absence of brushes also means less wear and tear. In brushed motors, brushes gradually wear out and need replacement, but BLDC Motors eliminate this issue entirely. This results in a longer operational lifespan and reduced maintenance costs, making them a cost-effective solution in the long run.

3. Precision and Control

Thanks to electronic commutation, BLDC Motors offer exceptional control over speed and torque. This precision is crucial in applications like robotics and medical equipment, where even the slightest variation can impact performance. The ability to fine-tune motor operations ensures smoother and more accurate results.

4. Compact and Lightweight Design

BLDC Motors are known for their compact and lightweight design, making them perfect for mini and micro applications. Whether it’s a tiny drone or a portable medical device, these motors deliver high performance without adding unnecessary bulk or weight.

5. Quiet and Smooth Operation

Without the physical contact of brushes, BLDC Motors operate more quietly and smoothly compared to brushed motors. This makes them ideal for use in environments where noise reduction is essential, such as in smart home appliances or office equipment.

6. Improved Thermal Performance

The electronic control system in BLDC Motors allows for better heat dissipation, reducing the risk of overheating. This improved thermal performance enhances the motor’s reliability, especially in high-demand applications like industrial automation and electric valves.

In summary, the combination of efficiency, durability, precision, and compact design makes Brushless DC Motors a versatile and reliable solution for a wide range of applications. Whether you’re designing a cutting-edge robot or a smart home device, BLDC Motors provide the performance and reliability you need.

Applications of Brushless DC Motors

Brushless DC Motors (BLDC Motors) are incredibly versatile, making them a popular choice across a wide range of industries. Their compact size, high efficiency, and precise control make them ideal for both mini and micro applications. Here are some of the most common uses of BLDC Motors:

1. Smart Home Devices

In the world of smart home technology, BLDC Motors play a crucial role. They power devices like automated blinds, smart locks, and HVAC systems, providing quiet and efficient operation. Their ability to deliver precise control ensures that these devices function seamlessly, enhancing the user experience.

2. Robotics

Robotics is another field where BLDC Motors shine. From robotic arms in manufacturing to drones and automated guided vehicles (AGVs), these motors offer the precision and reliability needed for complex tasks. Their lightweight design and high torque make them perfect for applications where space and performance are critical.

3. Medical Care

In the medical industry, BLDC Motors are used in a variety of equipment, including surgical tools, infusion pumps, and diagnostic devices. Their smooth and quiet operation, combined with precise control, ensures that medical procedures are carried out with the highest level of accuracy and safety.

4. Industrial Automation

BLDC Motors are widely used in industrial automation, powering conveyor systems, electric valves, and vending machines. Their durability and efficiency make them ideal for high-demand environments, where reliability and performance are essential.

5. Electric Vehicles

The automotive industry has also embraced BLDC Motors, particularly in electric vehicles (EVs). These motors are used in everything from power windows and windshield wipers to the main propulsion systems. Their high efficiency and compact size contribute to the overall performance and energy savings of EVs.

6. Consumer Electronics

From laptops and gaming consoles to cameras and drones, BLDC Motors are found in many consumer electronics. Their ability to operate quietly and efficiently makes them a preferred choice for devices that require precise motion control.

In conclusion, the versatility and performance of Brushless DC Motors make them indispensable in modern technology. Whether it’s improving the functionality of smart home devices, enhancing medical equipment, or powering industrial automation, BLDC Motors continue to drive innovation across industries.

Why Choose Etonm Motor for BLDC Motors?

When it comes to Brushless DC Motors (BLDC Motors), choosing the right manufacturer is crucial to ensure quality, reliability, and performance. At Etonm Motor, we specialize in designing and producing high-performance BLDC Motors tailored to meet the unique needs of our clients. Here’s why we stand out:

1. Expertise in Customization

At Etonm Motor, we understand that every application is different. Whether you need a mini BLDC Motor for a smart home device or a micro BLDC Motor for medical equipment, we offer customized solutions to match your specific requirements. Our team of experts works closely with you to design motors that deliver optimal performance.

2. Commitment to Quality

Quality is at the core of everything we do. Our BLDC Motors are manufactured using premium materials and state-of-the-art technology, ensuring durability and long-lasting performance. Each motor undergoes rigorous testing to meet the highest industry standards.

3. Focus on Innovation

Innovation drives us. We continuously invest in research and development to stay ahead of the curve in motor technology. Our Brushless DC Motors incorporate the latest advancements, offering improved efficiency, precision, and control for your applications.

4. Wide Range of Applications

Our BLDC Motors are trusted by clients across various industries, including smart home devices, robotics, medical care, and industrial automation. No matter the challenge, we have the expertise to provide motors that meet your needs.

5. Exceptional Customer Support

At Etonm Motor, we believe in building long-term relationships with our clients. Our dedicated support team is always available to assist you, from the initial consultation to after-sales service. We’re here to ensure your experience with us is seamless and satisfying.

6. Competitive Pricing

We offer high-quality BLDC Motors at competitive prices, ensuring you get the best value for your investment. Our efficient manufacturing processes allow us to deliver cost-effective solutions without compromising on quality.

Whether you’re looking for a standard Brushless DC Motor or a fully customized solution, Etonm Motor is your trusted partner. Contact us today to learn more about our products and how we can help power your next project.

Conclusion

Brushless DC Motors (BLDC Motors) have transformed the way we approach motion control in modern technology. From their efficient and brushless design to their precise electronic commutation, these motors offer unparalleled performance, durability, and versatility. Whether it’s powering smart home devices, enabling advanced robotics, or driving critical medical equipment, BLDC Motors continues to play a vital role in shaping the future of innovation.

In this article, we’ve explored how Brushless DC Motors work, their key components, and the numerous advantages they offer over traditional brushed motors. We’ve also highlighted their wide range of applications across industries, demonstrating why they are the preferred choice for engineers and designers worldwide.

At Etonm Motor, we are proud to be at the forefront of BLDC Motor technology. With our expertise in customization, commitment to quality, and focus on innovation, we provide motors that meet the highest standards of performance and reliability. Whether you’re working on a cutting-edge project or looking to improve an existing application, we’re here to help.

If you’re ready to take your project to the next level, contact Etonm Motor today. Explore our range of Brushless DC Motors and discover how we can power your success. Don’t forget to share this article with your network or leave a comment below—we’d love to hear your thoughts!

Related Reading

- What is KV Rating in Brushless Motors and How to Calculate It?

- Brushless DC Motor Troubleshooting: Common Issues and Solutions

- Why Use a DC Motor Controller for BLDC Motor?

- What are the Components of Brushless DC Motor? A Comprehensive Guide

- What Factors Affect the Performance of Brushless Motors? A Comprehensive Guide

- Top 5 Applications of Brushless DC Motors in Industrial Automation

- BLDC Motor vs Brushed Motor: Which is Better for Your Needs?

- What Are the Key Advantages of Brushless Motors?

- Brushless DC Motors: Applications In Smart Home, Medical & Robotics