”Ever wondered why your motor slows down or fails unexpectedly? Temperature rise could be the sneaky culprit. This post explores how heat impacts motor performance, efficiency, and longevity—plus tips to keep things running smoothly.”

Table of Contents

Introduction

Picture this: you’re midway through a project—maybe tweaking a robotic arm or testing a smart home gadget—when suddenly, the motor stalls. It’s not broken, but it’s sluggish, like it’s begging for a coffee break. Sound familiar? If so, temperature rise in motors might be the sneaky troublemaker behind those motor performance issues. Heat isn’t just a minor annoyance; it’s a game-changer for how motors run, whether they’re powering a vending machine, an electric valve, or a sanitary dispenser.

Here’s the deal: motors generate heat naturally while working, but when that heat climbs too high, things start to go south. Efficiency dips, components wear out faster, and before you know it, your once-reliable motor is on the fritz. In industries like robotics or medical care, where precision matters, that’s a big deal. So, what’s really going on when motors get too hot? And more importantly, how can you keep them humming along? In this post, we’ll break down how temperature rise messes with motor performance and lifespan—and share some practical tricks to beat the heat. Let’s dive in!

Why Temperature Rise Happens in Motors

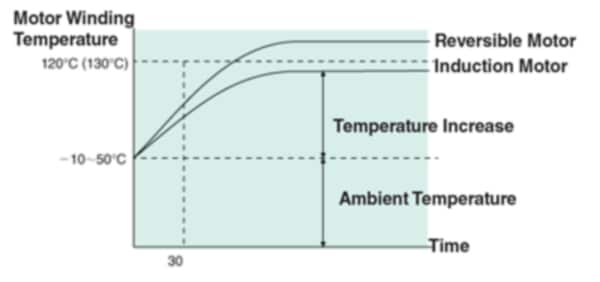

Motors are the unsung heroes of countless devices, but they don’t come without baggage—namely, heat. So, what’s behind this temperature rise? Let’s dig into the culprits.

1. Electrical Resistance: The Silent Heat Generator

It all starts with the basics of how motors work. When electricity flows through the windings—whether in a planetary gear motor or a brushless model—it encounters resistance. Think of it like water pushing through a narrow pipe: some energy gets lost as heat. The harder you drive the motor, the more current flows, and the hotter those windings get. This is ground zero for how heat affects motor efficiency, especially in high-power applications like robotics or electric valves.

2. Friction and Mechanical Stress

Then there’s the moving parts. In worm gear or flat gearbox motors, gears mesh and bearings spin, creating friction that’s tough to avoid. Over time, this mechanical grind generates heat, piling onto the electrical load. Poor lubrication or worn components only make it worse, stressing the motor’s thermal management systems. It’s like a workout that never ends—eventually, something’s got to give.

3. Load and Environment: The Wild Cards

Finally, external factors can tip the scales. Overloading a motor—say, in a vending machine jammed with goods—forces it to work harder, spiking temperatures fast. Add a hot, dusty environment or lousy ventilation, and you’re asking for trouble. Research shows a motor’s efficiency can drop 10% for every 10°C above its ideal range. That’s a wake-up call to keep heat in check!

How Heat Impacts Motor Performance

Heat isn’t just a nuisance—it’s a performance thief that can turn a reliable motor into a sluggish mess. Let’s unpack how temperature rise hits motor performance where it hurts, from efficiency to durability.

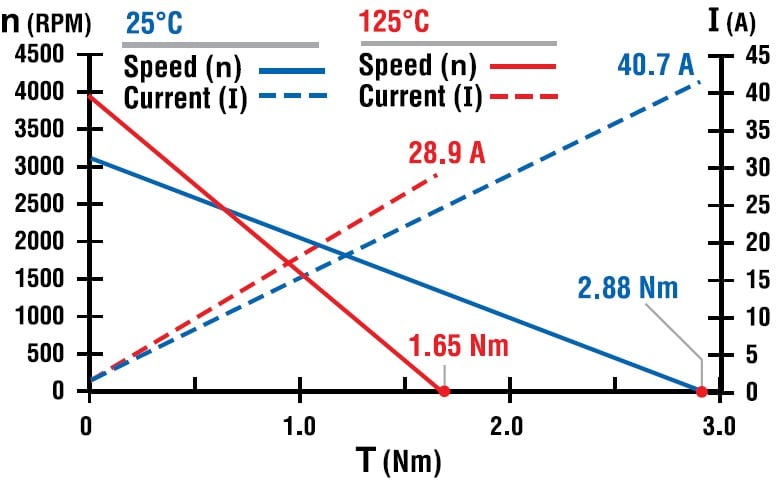

1. Efficiency Drops and Power Loss

First up, heat saps efficiency like a slow leak in a tire. As temperatures climb, electrical resistance in the windings increases, forcing the motor to work harder to deliver the same output. This is a big deal for motors in smart home devices or sanitary dispensers, where consistent power matters. For example, imagine a vending machine motor struggling to dispense a snack because heat’s cut its torque by 15%. That’s how heat affects motor efficiency—quietly but brutally. Over time, you’re burning more energy for less results, and nobody’s got time for that.

2. Wear and Tear on Components

Then there’s the long game: the temperature impact on motor lifespan. Excessive heat breaks down insulation around the windings, leaving them vulnerable to short circuits. Bearings take a hit too—high temps can degrade lubricants, leading to grinding and eventual failure. Picture a round gear motor in a security system running hot for months; one day, it just gives up. A study from the IEEE suggests motors operating 20°C above their limit can see lifespan slashed by half. That’s not wear and tear—that’s a heat-fueled demolition job. Whether it’s robotics or medical care equipment, these breakdowns mean downtime, repairs, and headaches you don’t need.

Heat’s no small fry—it’s a domino effect that starts with performance dips and ends with a motor on its last legs. Next, we’ll look at what happens when overheating hits the real world.

Real-World Consequences of Overheating

Heat doesn’t just mess with motors in theory—it can wreak havoc in the real world, turning small motor performance issues into big headaches. Let’s see how this plays out when the rubber meets the road.

Imagine a smart home thermostat relying on a micro DC motor to adjust vents. It’s a hot summer, and the motor’s been running nonstop. Poor ventilation lets the temperature soar, and soon, the motor’s efficiency tanks. One day, it stalls mid-adjustment—leaving the house sweltering and the homeowner fuming. That’s not just a glitch; it’s a failure that hits comfort and trust in the product. Preventing motor overheating could’ve saved the day, but instead, it’s a repair call waiting to happen.

Now scale that up. In robotics or medical care, like a surgical tool driven by a planetary gear motor, overheating isn’t just inconvenient—it’s critical. If heat degrades performance mid-procedure, precision falters, and outcomes suffer. Even in simpler setups, like vending machines or electric meters, a fried motor means lost revenue or inaccurate readings. I’ve seen manufacturers report downtime spikes when heat’s ignored—sometimes costing thousands in repairs or replacements. These aren’t hypotheticals; they’re the stakes when heat gets out of hand.

Overheating doesn’t discriminate—it’ll hit any motor, from sanitary dispensers to security systems, where reliability is non-negotiable. So, how do we fight back? Let’s talk solutions next.

Tips to Manage Temperature Rise in Motors

Heat’s a motor’s worst enemy, but you don’t have to let it win. Here are some battle-tested tips to keep temperature rise in check and your motors running strong.

Design and Material Choices

It starts with the build. Opt for motors designed with motor thermal management in mind—like heat-resistant windings or casings that wick away heat. For instance, brushless motors often handle heat better than traditional ones thanks to fewer friction points. Ventilation’s a game-changer too—think slotted housings or fans in high-load setups like robotics. I once saw a planetary gear motor last twice as long just because the designer swapped in a heat-dissipating alloy. Curious about picking the right motor? Check our guide on choosing gear motors for more on that.

Operational Best Practices

How you run a motor matters just as much. Overloading’s a rookie mistake—keep loads within spec, especially for sensitive gigs like medical devices or electric valves. Regular maintenance is your friend: clean out dust, check lubrication, and monitor temps with a cheap infrared thermometer. Preventing motor overheating isn’t rocket science; it’s about consistency. A buddy of mine in vending machine repair swears by scheduled cooldown breaks for heavy-use units—saved him a fortune in replacements. Want deeper tech on heat control? The IEEE’s thermal studies have some solid data to back this up.

Smart design and simple habits can tame heat before it spirals. Your motors—and your sanity—will thank you for it.

Conclusion

Temperature rise in motors isn’t just a technical quirk—it’s a make-or-break factor for motor performance and lifespan. We’ve seen how heat sneaks in through resistance, friction, and overloads, slashing efficiency and wearing out parts faster than you’d like. From a stalled smart home gadget to a robotics meltdown, the real-world fallout is no joke. But here’s the good news: with smart design choices and a little operational TLC, you can keep overheating at bay and your motors humming happily.

So, what’s your take? Ever had a motor crap out on you because of heat? If you’re hungry for more tips, swing by our motor maintenance guide for a deeper dive. Let’s keep those motors cool and kicking!

Related Reading

- Why Choose 24v Small DC Motors?

- 12V DC Motor High Torque Low RPM Performance

- How to Calculate Transmission Gear Ratio: A Comprehensive Guide for Gear Systems

- The Ultimate Guide to Brushless DC Motors: Types, Applications, and Benefits

- BLDC Motor vs Brushed Motor: Which is Better for Your Needs?

- AC Motors vs DC Motors: Which is Best for Your Application?

- The Ultimate Guide to Troubleshooting BLDC Worm Gear Motors in 2025

- What Factors Affect the Performance of Brushless Motors? A Comprehensive Guide

- Brushless DC Motor Troubleshooting: Common Issues and Solutions

- How to Install a Brushless DC Motor: Expert Step-by-Step Guide

- How to Increase Torque in Brushless DC Motors: A Practical Guide

- What is Electronic Speed Control (ESC) for Brushless DC Motors?

- Exploring Types of Micro Motors and Their Future Trends