"Looking for a 12V DC motor? Learn how RPM affects performance and find the perfect match—whether it’s a low RPM motor for precision or a 1000 RPM model for speed—with Etonm Motor’s expert guide."

Table of Contents

Why RPM Matters When Choosing a 12V DC Motor

When selecting a 12V DC motor for your next project, one factor towers above the rest: RPM, or revolutions per minute. It’s not just a spec on a datasheet—it’s the pulse driving your motor’s performance, shaping how fast it spins and how much power it delivers. Whether you’re building a smart home gadget, a robotic arm, or a vending machine component, the RPM of your 12V DC motor can determine success or struggle. Pick a speed too low, and your system might crawl; go too high, and you could lose the torque needed to move the load.

Why does RPM hold such weight? It’s the link between speed and functionality. A motor running at 5-100 RPM offers precision and strength for tasks needing careful control, while a 12V DC motor hitting 1000 RPM excels where rapid rotation rules. With so many options, choosing the right RPM isn’t about hitting a random number—it’s about syncing your motor with your project’s demands. In this guide, we’ll walk you through the essentials of picking the perfect 12V DC motor by RPM, from the basics to real-world applications. Let’s dive in with Etonm Motor as your guide.

Understanding RPM: The Basics of Speed and Torque

Before you settle on a 12V DC motor, it’s worth understanding what RPM means and how it steers performance. RPM—revolutions per minute—tells you how many full turns a motor’s shaft makes in 60 seconds. It’s a simple metric with a big impact, directly affecting two core traits of a 12V DC motor: speed and torque. Getting a handle on this relationship is your first step to a smart choice.

Here’s the rundown. Higher RPM equals faster spinning—plain and simple. A 12V DC motor at 1000 RPM will outrun one chugging at 50 RPM every time. But there’s a trade-off: as RPM climbs, torque—the force that powers your load—usually drops. Imagine a robotic arm hoisting a heavy part. A low-RPM motor, say 5-100 RPM, brings the muscle to lift it steadily. Flip that around, and a high-RPM motor might spin a lightweight fan blade fast but falter under heavier weight.

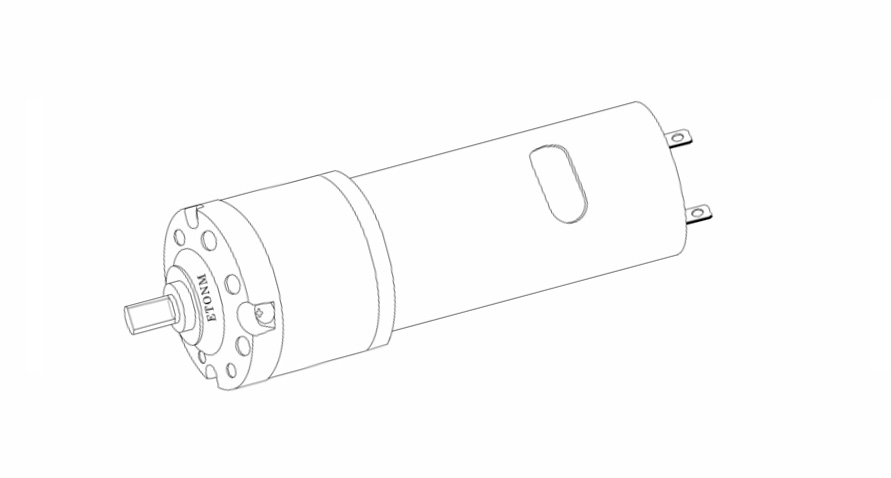

This isn’t a flaw—it’s physics doing its thing. In a 12V DC motor, power (in watts) comes from speed times torque. With voltage capped at 12V, boosting speed cuts the force, and vice versa. Etonm Motor designs its micro DC motors with this balance in mind, offering a range of RPMs to fit your needs. Whether you lean toward rapid motion or steady strength, grasping RPM’s role sets you up for success. Let’s see how this plays out in practice.

12V DC Motor Low RPM Uses (5-100 RPM)

When precision and power trump speed, a 12V DC motor with low RPM—think 5-100 RPM—steps up. These motors are champs at delivering controlled motion and high torque, perfect for jobs where slow and steady wins the race. Unlike high-RPM models, they trade velocity for force, making them a favorite for engineers tackling intricate or heavy-duty tasks.

Take smart home systems. A motorized curtain track or window opener often uses a 12V DC motor with low RPM to glide smoothly and stop precisely. At speeds as low as 5 RPM, you get quiet operation and exact positioning, while the extra torque handles the weight of curtains or glass. The same goes for sanitary dispensers—think soap pumps or towel units—where a low-RPM motor ensures consistent flow without mess or jams.

Robotics loves these motors too. A robotic joint or gripper needs deliberate motion to place parts or grab objects securely. A 12V DC motor at 50-100 RPM can lift a load with torque boosted by 20-50% over faster models, all while keeping things stable. Etonm Motor’s planetary gear motors, for instance, pack this kind of power into compact builds, ideal for such precision work. From medical actuators to slow-turning security locks, low-RPM motors show that slower can indeed be stronger.

High RPM 12V DC Motor Applications (1000-3000 RPM)

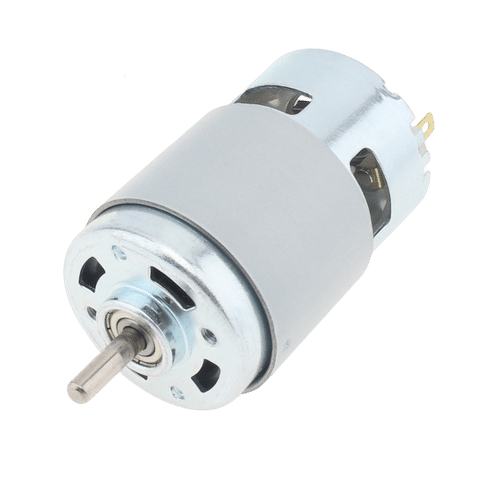

When speed takes center stage, a 12V DC motor running at 1000-3000 RPM steals the show. These high-RPM motors are all about quick spins and fast reactions, shining in setups where pace beats precision. They might not match the torque of low-RPM options, but their knack for rapid rotation makes them perfect for dynamic, motion-driven projects.

Vending machines are a great example. Coin sorters or product dispensers often tap a 12V DC motor at 1000 RPM or more to zip through transactions. That fast spin cuts wait times, keeping users happy—because a slow snack machine is nobody’s friend. In medical care, small fans in devices like ventilators or diagnostic tools lean on high-RPM motors for airflow. A 2000 RPM motor keeps things cool and compact, a big win for portable gear.

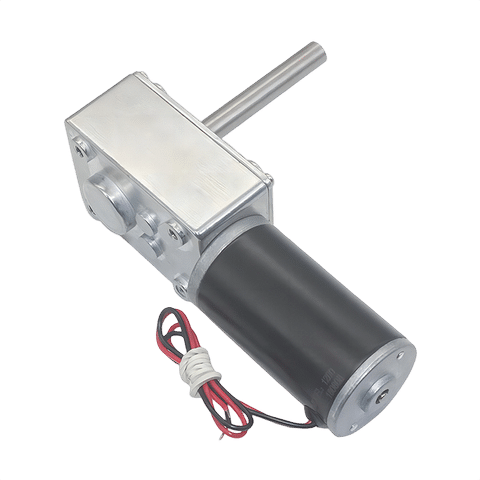

Security systems also cash in on this speed. A rotating surveillance camera might use a 12V DC motor at 1000-1500 RPM to pivot fast, tracking motion or scanning areas in real time. Etonm Motor’s brushless DC motors bring efficiency and longevity to these high-speed roles, holding up under constant use. Sure, lower torque limits them to lighter loads, but for rapid-action tasks like actuators or spinning displays, these motors prove speed can be a superpower.

How to Match RPM to Your Project Needs

Picking the right RPM for your 12V DC motor isn’t a shot in the dark—it’s about syncing performance with purpose. Whether you’re eyeing the control of a low-RPM motor or the zip of a 12V DC motor at 1000 RPM, a few clear steps can point you to the winner. Here’s how to nail it.

Step 1: Define Your Load and Speed Needs

First, pin down the task. Moving a heavy load—like a robotic arm with tools—calls for a low-RPM motor (5-100 RPM) with torque to spare. Lighter jobs, like spinning a fan or camera lens, thrive with a high-RPM motor (1000-3000 RPM) built for speed. A vending machine ejector might demand 1500 RPM for quick drops, while a smart lock hums at 50 RPM for secure turns. Know your load and pace upfront.

Step 2: Factor in the Environment

Next, consider the setting. High heat or dust can tax a 12V DC motor at 1000 RPM, wearing it down if it’s not up to snuff. A low-RPM motor in tight quarters might need a slim gearbox to fit. Etonm Motor’s flat gearbox motors, for example, squeeze into small spaces without skimping on power. Noise matters too—low RPM often means less racket, a plus for home gadgets.

Step 3: Customize with Your Supplier

Off-the-shelf motors might not cut it for unique jobs. Need a 12V DC motor at 800 RPM? Or a hybrid balancing torque and speed? Customization is your ace. At Etonm Motor, we tweak RPM, gearing, and more to fit your specs perfectly. Explore our Micro DC Motors page for ideas, then let’s talk details.

Matching RPM to your project is straightforward when you break it down. Assess your load, environment, and options, and you’ll find a 12V DC motor that hits the mark—right where it matters.

Conclusion: Customize Your RPM Solution with Etonm Motor

Choosing the right RPM for your 12V DC motor isn’t a minor detail—it’s what powers your project’s success. A 12V DC motor with low RPM brings precision to robotics or smart homes, while a 1000 RPM model drives speed in vending machines and security cams. It’s all about fit, and getting it right keeps your design running like clockwork.

Etonm Motor makes that fit happen. With motors from 5 RPM to 3000 RPM, we’ve got the range and the know-how to customize for any challenge. Need a 12V DC motor at 1000 RPM for a fast actuator? Or a low-RPM beast for a tough valve? Our planetary gear and brushless options deliver, tailored to your specs. We’re here to turn your vision into reality.

Ready to power up your next idea? Swing by our Micro DC Motors page to browse, or drop us a line for a custom consult. With Etonm Motor, the perfect RPM is just the beginning—let’s make it happen together.

Explore Our 12v DC Motors

Related Reading

- How to Choose the Perfect 12V DC Gear Motor

- Small but Mighty: Mastering Small High Torque 12V Motors

- Low Speed, High Torque: Why 12V Motors Are Perfect for Your DIY Projects

- Tailored Power: High Torque Custom 12V Motors for Pros

- 1000 RPM and Beyond: High Performance 12V DC Motors

- 12V High Torque DC Motors: Your Guide to Power and Precision

- High Torque Gear Motors: Unleashing 12V Power for Robotics

- DC Motor Speed Controller 12V Basics: From Brushed to BLDC