Discover how to select the perfect brushless gear motor for your needs. Learn about key factors like torque, speed, efficiency, and more to make an informed decision.

Table of Contents

Introduction

Brushless gear motors have become the go-to solution for engineers and designers when powering modern devices—from smart home appliances to advanced robotics. These compact, efficient, and reliable motors, also known as brushless DC motors (BLDC), offer significant advantages over traditional brushed motors, making them ideal for a wide range of applications. Whether you’re developing a high-precision medical device, a vending machine, or an electric valve, choosing the right brushless gear motor is critical to ensuring optimal performance and longevity.

However, with so many options available, selecting the perfect motor for your specific needs can be challenging. Factors like torque, speed, efficiency, and environmental conditions all play a role in determining which motor is the best fit. In this guide, we’ll walk you through the key considerations to help you make an informed decision. By the end, you’ll have a clear understanding of how to choose a brushless gear motor that meets your application’s requirements while delivering maximum value. Let’s dive in!

What is a Brushless Gear Motor?

A brushless gear motor is a type of electric motor that combines the efficiency of a brushless DC motor (BLDC) with the mechanical advantages of a gearbox. Unlike traditional brushed motors, which use physical brushes to transfer electrical current to the rotor, brushless motors rely on electronic controllers to manage the flow of current. This design eliminates the need for brushes, reducing friction, wear, and maintenance while improving overall performance.

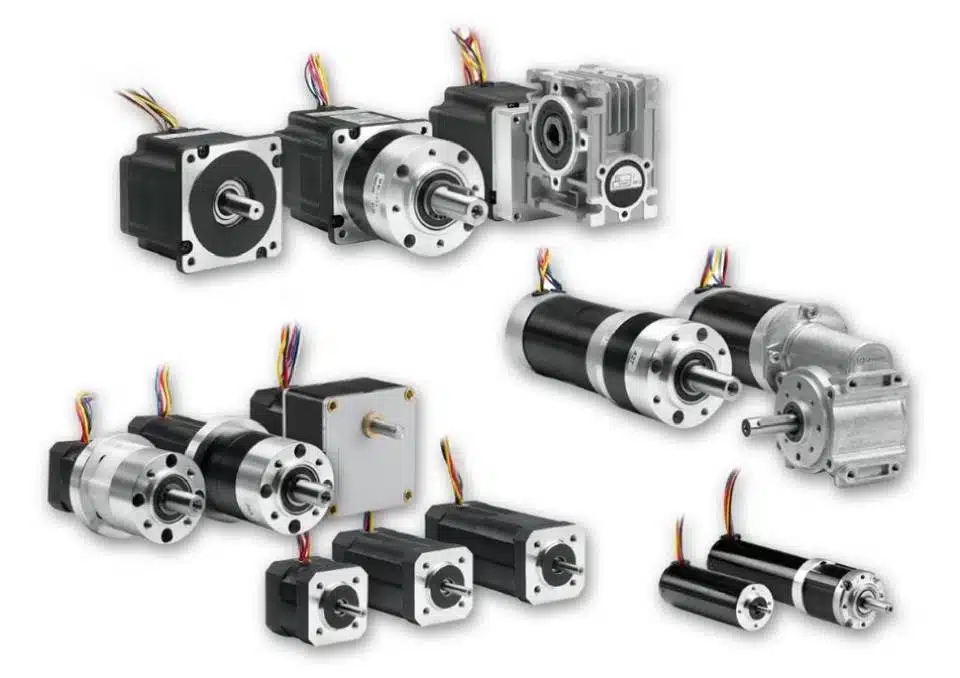

The “gear” component of a brushless gear motor refers to the integrated gearbox, which adjusts the motor’s output speed and torque to match the requirements of the application. By pairing a brushless motor with a gearbox, these motors deliver precise control, higher efficiency, and smoother operation—making them ideal for applications where space, reliability, and energy efficiency are critical.

Brushless DC motors (BLDC) are known for their high power density, long lifespan, and ability to operate at varying speeds without sacrificing performance. These features, combined with the versatility of gear systems, make brushless gear motors a popular choice for industries like smart home devices, medical equipment, robotics, and industrial automation. Whether you need a compact motor for a miniaturized device or a high-torque solution for heavy-duty tasks, brushless gear motors offer a reliable and efficient option.

In the next sections, we’ll explore the key factors to consider when selecting a brushless gear motor, helping you find the perfect match for your specific application.

Key Factors to Consider When Choosing a Brushless Gear Motor

1. Application Requirements

When choosing a brushless gear motor, the first and most critical step is to understand your application’s specific requirements. Every application has unique demands, and selecting a motor that aligns with these needs ensures optimal performance and longevity. Here are some key aspects to consider:

Load Requirements:

The load your motor will drive directly impacts the type of brushless gear motor you need. For example, a robotic arm lifting heavy objects requires a high-torque motor, while a small fan in a smart home device might need a motor optimized for speed and efficiency. Assess the weight, size, and resistance of the load to determine the necessary torque and power output.Speed and Precision:

Different applications require varying levels of speed and precision. In medical devices like infusion pumps, precise control, and consistent speed are crucial, whereas in vending machines, moderate speed with reliable operation is more important. Brushless gear motors excel in providing adjustable speed ranges and smooth operation, making them suitable for both high-precision and general-purpose tasks.Duty Cycle:

Consider how often and how long the motor will operate. Continuous-duty applications, such as electric valves or conveyor systems, require motors designed to handle prolonged use without overheating. On the other hand, intermittent-duty applications, like automatic dispensers, may allow for smaller, more cost-effective motors.Environmental Conditions:

The operating environment plays a significant role in motor selection. Will the motor be exposed to extreme temperatures, moisture, or dust? For instance, motors used in outdoor security cameras need to withstand weather conditions, while those in sanitary dispensers must resist exposure to cleaning agents. Look for motors with appropriate IP ratings and materials that can endure your application’s environmental challenges.

By thoroughly evaluating these factors, you can narrow down your options and choose a brushless gear motor that perfectly matches your application’s demands. In the next section, we’ll dive into another critical consideration: motor size and weight.

2. Motor Size and Weight

In many modern applications, especially those involving mini or micro devices, the size and weight of a brushless gear motor are critical factors. Compact and lightweight motors are often essential for ensuring seamless integration into space-constrained designs without compromising performance. Here’s why size and weight matter and how to choose the right motor for your needs:

Space Constraints:

Many applications, such as smart home devices, medical equipment, and robotics, have limited space for motor installation. A bulky motor can disrupt the design or functionality of the device. Brushless gear motors, particularly those designed by Etonm Motor, are engineered to be compact while delivering high power density, making them ideal for miniaturized systems.Weight Considerations:

In applications like drones, portable medical devices, or wearable technology, the weight of the motor can significantly impact overall performance. Heavy motors can reduce battery life, limit mobility, or increase operational costs. Brushless gear motors are inherently lightweight due to their efficient design and lack of brushes, making them a preferred choice for weight-sensitive applications.Power-to-Size Ratio:

One of the standout features of brushless gear motors is their exceptional power-to-size ratio. Despite their small dimensions, these motors can deliver impressive torque and speed, ensuring they meet the demands of high-performance applications without taking up excessive space.Customization Options:

If standard motor sizes don’t fit your requirements, many manufacturers, including Etonm Motor, offer customization services. Whether you need a specific shaft size, mounting configuration, or gear ratio, custom solutions can help you achieve the perfect balance between size, weight, and performance.

When evaluating motor size and weight, always consider the trade-offs. While smaller motors save space and reduce weight, ensure they still meet your application’s torque, speed, and durability requirements. In the next section, we’ll explore another crucial factor: efficiency and power consumption, which can significantly impact the overall performance and sustainability of your application.

3. Efficiency and Power Consumption

Efficiency and power consumption are critical factors when selecting a brushless gear motor, especially in applications where energy savings and sustainability are priorities. Brushless DC motors (BLDC) are renowned for their high efficiency, but understanding how to maximize this advantage can help you make the best choice for your application. Here’s what you need to know:

Why Efficiency Matters:

Brushless gear motors are inherently more efficient than their brushed counterparts because they eliminate the friction and energy loss associated with brushes. This efficiency translates to lower power consumption, reduced heat generation, and longer operational life. For battery-powered devices like portable medical equipment or smart home devices, higher efficiency means extended battery life and fewer replacements.Energy Savings:

In applications where motors run continuously, such as electric valves or industrial automation systems, even small improvements in efficiency can lead to significant energy savings over time. This not only reduces operational costs but also supports sustainability goals by minimizing energy waste.Heat Management:

Efficient motors generate less heat, which is particularly important in compact or enclosed systems where overheating can damage components or degrade performance. Brushless gear motors, with their low heat output, are well-suited for applications like vending machines or security systems that require reliable, long-term operation.Power Consumption Considerations:

When evaluating power consumption, consider both the motor’s rated power and its actual usage in your application. For example, a motor with a high power rating might seem efficient, but if it’s oversized for your needs, it could consume more energy than necessary. Matching the motor’s power output to your application’s requirements ensures optimal efficiency.Regenerative Braking (Optional):

Some advanced brushless gear motors feature regenerative braking, which recovers energy during deceleration and feeds it back into the system. This feature is particularly useful in applications like robotics or electric vehicles, where frequent starts and stops are common.

By prioritizing efficiency and power consumption, you can select a brushless gear motor that not only meets your performance needs but also aligns with your energy-saving and sustainability goals. In the next section, we’ll dive into another essential factor: speed and torque, and how to balance these to achieve the best results for your application.

4. Speed and Torque

When selecting a brushless gear motor, understanding the relationship between speed and torque is crucial. These two factors are often inversely related, meaning that as one increases, the other may decrease. Striking the right balance between speed and torque ensures your motor performs optimally for your specific application. Here’s how to navigate this critical consideration:

Understanding Speed and Torque:

Speed refers to how fast the motor’s output shaft rotates, typically measured in revolutions per minute (RPM). High-speed motors are ideal for applications like fans or conveyor belts.

Torque is the rotational force the motor can generate, usually measured in Newton-meters (Nm) or ounce-inches (oz-in). High-torque motors are essential for tasks requiring significant force, such as lifting heavy loads in robotics or driving electric valves.

Gear Ratios and Their Impact:

The gearbox in a brushless gear motor plays a key role in adjusting speed and torque. A higher gear ratio reduces output speed but increases torque, making it suitable for applications like industrial machinery or medical devices that require precise, powerful movements. Conversely, a lower gear ratio increases speed while reducing torque, which is ideal for applications like vending machines or small appliances.Matching Speed and Torque to Your Application:

For robotics or automated systems, you may need a motor that offers a balance of speed and torque to handle dynamic movements and varying loads.

In smart home devices like automatic curtains or door openers, moderate torque with consistent speed is often sufficient.

For electric valves or pumps, high torque at low speeds ensures reliable operation under pressure.

Variable Speed Control:

One of the advantages of brushless DC motors (BLDC) is their ability to operate efficiently across a wide range of speeds. This makes them ideal for applications requiring variable speed control, such as HVAC systems or electric vehicles.Real-World Example:

Consider a sanitary dispenser: it requires a motor with enough torque to push out soap or sanitizer but doesn’t need high speed. A brushless gear motor with an appropriate gear ratio ensures smooth, reliable operation without unnecessary energy consumption.

By carefully analyzing your application’s speed and torque requirements, you can select a brushless gear motor that delivers the right performance. In the next section, we’ll explore how environmental conditions can influence your motor choice and what to look for to ensure durability and reliability.

5. Environmental Conditions

The environment in which a brushless gear motor operates can significantly impact its performance, durability, and lifespan. Whether your application involves extreme temperatures, moisture, dust, or exposure to chemicals, selecting a motor designed to withstand these conditions is essential. Here’s what to consider when evaluating environmental factors:

Temperature Extremes:

Motors used in applications like outdoor security systems or industrial machinery may be exposed to high or low temperatures. Excessive heat can cause motor components to degrade, while extreme cold can affect lubrication and material flexibility. Look for motors with a wide operating temperature range and materials that can handle thermal stress.Moisture and Humidity:

In environments with high humidity or direct exposure to water, such as sanitary dispensers or marine equipment, moisture resistance is critical. Motors with high IP (Ingress Protection) ratings, such as IP65 or IP67, are designed to prevent water and dust ingress, ensuring reliable operation in wet or damp conditions.Dust and Debris:

Applications like vending machines or agricultural equipment often operate in dusty environments. Dust and debris can clog motor components, leading to overheating or failure. Brushless gear motors with sealed housings and high IP ratings are ideal for such conditions.Chemical Exposure:

In industries like medical care or food processing, motors may come into contact with cleaning agents, disinfectants, or other chemicals. Choosing motors made from corrosion-resistant materials, such as stainless steel or specially coated components, ensures longevity and reliability.Vibration and Shock:

For applications like robotics or automotive systems, motors must withstand vibrations and shocks without compromising performance. Brushless gear motors with robust construction and secure mounting options are better suited for these demanding environments.Noise Levels:

In settings like smart home devices or medical equipment, low noise operation is often a priority. Brushless motors are inherently quieter than brushed motors, but additional design features, such as precision gearboxes and vibration dampening, can further reduce noise levels.

By carefully assessing the environmental conditions of your application, you can choose a brushless gear motor that not only meets performance requirements but also stands up to the challenges of its operating environment. In the next section, we’ll discuss why Etonm Motor is the ideal partner for your brushless gear motor needs, offering customized solutions tailored to your specific requirements.

Why Choose Etonm Motor for Your Brushless Gear Motor Needs?

When it comes to selecting a brushless gear motor, partnering with a reliable and experienced manufacturer can make all the difference. At Etonm Motor, we specialize in designing and producing high-quality brushless gear motors tailored to meet the unique demands of your application. Here’s why we stand out as the ideal choice:

Expertise in Customization:

Every application is unique, and off-the-shelf solutions often fall short of meeting specific requirements. At Etonm Motor, we offer fully customizable brushless gear motors, allowing you to specify parameters like size, torque, speed, and gear ratios. Whether you need a mini motor for a smart home device or a high-torque solution for industrial automation, we can deliver a motor that fits your exact needs.Commitment to Quality:

Quality is at the core of everything we do. Our brushless gear motors are manufactured using premium materials and advanced production techniques, ensuring exceptional performance, durability, and reliability. Rigorous testing and quality control processes guarantee that every motor meets the highest industry standards.Wide Range of Applications:

With years of experience serving industries like smart homes, medical care, robotics, and industrial automation, we understand the diverse challenges our customers face. Our motors are designed to excel in a variety of environments, from compact consumer devices to heavy-duty industrial equipment.Energy Efficiency and Innovation:

As a forward-thinking manufacturer, we prioritize energy efficiency and sustainability. Our brushless gear motors are engineered to deliver maximum performance with minimal power consumption, helping you reduce operational costs and environmental impact. We also stay at the forefront of technological advancements, incorporating the latest innovations into our products.Exceptional Customer Support:

At Etonm Motor, we believe in building long-term relationships with our customers. Our team of experts is always available to provide technical guidance, answer questions, and assist with motor selection. From initial consultation to after-sales support, we’re here to ensure your complete satisfaction.Proven Track Record:

Our motors power a wide range of applications worldwide, from electric valves and vending machines to medical devices and security systems. Our proven track record and positive customer feedback are a testament to the reliability and performance of our products.

Choosing the right brushless gear motor is a critical decision, and Etonm Motor is here to make that process seamless. Whether you need a standard solution or a fully customized motor, we have the expertise and resources to deliver exceptional results.

Conclusion

Choosing the right brushless gear motor for your application doesn’t have to be overwhelming. By understanding your specific requirements—such as application needs, motor size and weight, efficiency, speed and torque, and environmental conditions—you can make an informed decision that ensures optimal performance and longevity. Brushless gear motors, with their high efficiency, compact design, and versatility, are an excellent choice for a wide range of industries, from smart home devices and medical equipment to robotics and industrial automation.

At Etonm Motor, we’re committed to helping you find the perfect motor solution. With our expertise in customization, dedication to quality, and focus on innovation, we provide brushless gear motors that meet the highest standards of performance and reliability. Whether you’re designing a cutting-edge product or upgrading an existing system, we’re here to support you every step of the way.

Ready to take the next step? Explore our range of brushless gear motors or contact our team today to discuss your specific needs. Let Etonm Motor be your trusted partner in powering the future of technology.

Related Reading

- How Does a Brushless DC Motor Work? A Complete Guide to BLDC Motors

- What are the Components of Brushless DC Motor? A Comprehensive Guide

- How to Choose the Right Brushless Motor for Your Drone: A Complete Guide

- How to Choose the Right BLDC Motor for Robotics Applications

- The Ultimate Guide to Brushless DC Motors: Types, Applications, and Benefits

- How to Choose the Right Curtain Motor: Key Factors and Expert Tips

- How to Choose the Right Planetary Gear Motor for Your Application

- What Are the Key Advantages of Brushless Motors?

- Brushless DC Motors: Applications In Smart Home, Medical & Robotics