Choosing the right Brushless DC Motor (BLDC Motor) for robotics applications can be challenging. This guide covers key factors like torque, speed, size, and control to help you select the perfect motor for your robotic project.

Table of Contents

Introduction

When it comes to robotics, the heart of any great design lies in its motor. And if you’re working on a robotics project, chances are you’ve heard about Brushless DC Motors (BLDC Motors). These motors are the unsung heroes behind everything from nimble robotic arms to high-flying drones. But here’s the thing: not all BLDC Motors are created equal. Choosing the right one for your robotics application can feel like navigating a maze—exciting but a bit overwhelming.

Why does it matter so much? Well, the motor you pick can make or break your robot’s performance. Whether you’re building a precision robotic arm for surgery, a high-speed drone for aerial photography, or an autonomous vehicle for logistics, the motor needs to deliver the right balance of torque, speed, and control. And let’s not forget about size and weight—because in robotics, every gram and millimeter counts.

But don’t worry, you’re not alone in this. In this guide, we’ll walk you through everything you need to know about choosing the perfect BLDC Motor for your robotics project. We’ll cover the key factors to consider, like torque, speed, and power requirements, and even dive into the different types of BLDC Motors that might be the best fit for your needs. By the end of this, you’ll have a clear roadmap to finding the motor that will bring your robotic creation to life.

So, let’s get started and make sure your robot has the powerhouse it deserves!

Understanding Robotics Requirements

Before diving into the technical details of Brushless DC Motors (BLDC Motors), it’s important to take a step back and ask: What does your robot actually need? Robotics is a broad field, and the requirements for a high-speed drone are vastly different from those of a precision surgical robot. Understanding these needs is the first step in choosing the right BLDC Motor for your application.

What Makes Robotics Unique?

Robotics applications are all about precision, efficiency, and durability. Whether your robot is performing delicate surgical tasks or navigating rough terrain, the motor needs to deliver consistent performance without fail. Here’s what sets robotics apart:

Precision: Robots often need to perform highly accurate movements, whether it’s a robotic arm placing a tiny component or a drone stabilizing in mid-air.

Efficiency: Many robots, especially those powered by batteries, need to maximize energy usage to extend operational time.

Durability: Robots often operate in demanding environments, from factory floors to outdoor terrains, so the motor must be robust and reliable.

Why BLDC Motors are Perfect for Robotics

This is where BLDC Motors shine. Unlike traditional brushed motors, BLDC Motors use electronic commutation, which eliminates the physical wear and tear caused by brushes. This means:

Smoother Operation: BLDC Motors provide consistent performance, which is crucial for precise robotic movements.

Higher Efficiency: With no energy lost to brush friction, BLDC Motors are more energy-efficient, making them ideal for battery-powered robots.

Longer Lifespan: The absence of brushes means less maintenance and a longer operational life, reducing downtime and costs.

Matching Motor Performance to Robotics Needs

Every robotics application has unique demands. For example:

Robotic Arms: These require high torque and precise control to handle tasks like lifting, placing, and assembling.

Drones: High speed and lightweight design are critical for stable and efficient flight.

Autonomous Vehicles: These need a balance of torque, speed, and durability to navigate various terrains and carry loads.

By understanding the specific requirements of your robotics project, you can narrow down the type of BLDC Motor that will deliver the best performance. In the next section, we’ll dive into the key factors you need to consider when choosing a BLDC Motor for robotics.

Key Factors to Consider When Choosing a BLDC Motor

Now that we’ve covered the unique requirements of robotics applications, it’s time to dive into the key factors you need to consider when selecting a Brushless DC Motor (BLDC Motor). Choosing the right motor isn’t just about picking the most powerful one—it’s about finding the perfect balance of torque, speed, size, control, and power requirements to match your robot’s needs. Let’s break it down.

1. Torque: The Muscle Behind the Movement

Torque is the rotational force that allows your robot to perform tasks like lifting, pushing, or turning. In robotics, torque is critical for applications like:

- Robotic Arms: Need high torque to lift and manipulate objects.

- Autonomous Vehicles: Require torque to navigate uneven terrain or carry heavy loads.

How to Determine Torque Requirements:

- Calculate the load your robot needs to handle.

- Consider the force required to move that load, including friction and inertia.

- Choose a motor with enough torque to handle the peak load, not just the average.

2. Speed: Finding the Right Pace

Speed is all about how fast your motor can rotate, measured in RPM (Revolutions Per Minute). While high speed is great for applications like drones, other robots, like surgical robots, may need slower, more controlled movements.

Balancing Speed and Torque:

- High-speed motors often sacrifice torque, so you’ll need to find a balance.

- For applications requiring both speed and torque, consider using a geared BLDC Motor to increase torque without sacrificing speed.

3. Size and Weight: Every Gram Counts

In robotics, space is often at a premium, and weight can significantly impact performance—especially for flying robots like drones.

Why Size and Weight Matter:

- Compact Motors: Fit into tight spaces, making them ideal for small robots or devices.

- Lightweight Motors: Reduce the overall weight of the robot, improving efficiency and maneuverability.

Tip: Look for motors with a high power-to-weight ratio to maximize performance without adding bulk.

4. Control and Precision: The Art of Fine-Tuning

Robotics often requires precise movements, whether it’s a robotic arm placing a tiny component or a drone stabilizing in mid-air. BLDC Motors excel in this area thanks to their electronic commutation, which allows for:

- Smooth Operation: No jerky movements, just consistent, precise control.

- Variable Speed: Easily adjust the motor’s speed to match the task at hand.

Applications Requiring Precision:

- Surgical Robots: Need exact movements for delicate procedures.

- CNC Machines: Require precise control for accurate machining.

5. Power Requirements: Matching Your Robot’s Energy Needs

The power requirements of your motor must align with your robot’s power supply. This includes:

- Voltage: Ensure the motor operates within your robot’s voltage range.

- Current: Check the motor’s current draw to avoid overloading your power source.

- Efficiency: Choose a motor with high efficiency to maximize battery life in portable robots.

Tip: Always leave some headroom in your power supply to handle peak loads without issues.

Why These Factors Matter

Choosing the right BLDC Motor isn’t just about picking the most powerful or fastest option—it’s about finding the motor that perfectly matches your robot’s needs. By carefully considering torque, speed, size, control, and power requirements, you can ensure your robot performs at its best, whether it’s flying through the air, navigating rough terrain, or performing delicate surgical tasks.

In the next section, we’ll explore the different Types of BLDC Motors and how they cater to specific robotics applications.

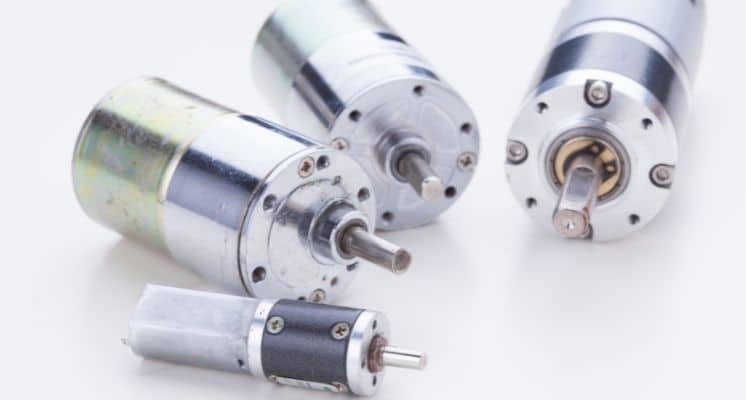

Types of BLDC Motors for Robotics

Now that we’ve covered the key factors to consider when choosing a Brushless DC Motor (BLDC Motor), let’s dive into the different types of BLDC Motors available and how they cater to specific robotics applications. Not all BLDC Motors are the same, and understanding their differences can help you pick the perfect motor for your robot.

1. Inner Rotor BLDC Motors

Inner Rotor BLDC Motors are the most common type, where the rotor (the rotating part) is located inside the stator (the stationary part). These motors are known for their:

High Speed: The compact rotor design allows for faster rotation, making them ideal for applications requiring high RPMs.

Low Inertia: The lightweight rotor enables quick acceleration and deceleration, perfect for responsive robotics tasks.

Best For:

Drones: High-speed rotation is essential for stable and efficient flight.

Robotic Arms: Quick, precise movements are needed for tasks like assembly or pick-and-place operations.

Example: A drone’s propellers are often powered by Inner Rotor BLDC Motors to achieve high speeds and agile maneuverability.

2. Outer Rotor BLDC Motors

In Outer Rotor BLDC Motors, the rotor surrounds the stator. This design offers:

Higher Torque: The larger rotor diameter provides greater torque, making these motors ideal for heavy-duty applications.

Compact Design: Despite their high torque, Outer Rotor BLDC Motors are often more compact than other motor types.

Best For:

Robotic Arms: High torque is needed to lift and manipulate heavy objects.

Wheeled Robots: These motors provide the power needed to navigate rough terrain or carry heavy loads.

Example: A robotic arm used in manufacturing might use an Outer Rotor BLDC Motor to handle heavy components with precision.

3. Disc Rotor BLDC Motors

Disc Rotor BLDC Motors feature a flat, disc-shaped rotor that is mounted perpendicular to the stator. These motors are known for their:

Ultra-Compact Size: The flat design makes them ideal for applications with strict space constraints.

Low Noise: Disc Rotor BLDC Motors operate quietly, making them suitable for noise-sensitive environments.

Best For:

Medical Robots: Compact size and quiet operation are critical for surgical tools and diagnostic equipment.

Small Drones: Lightweight and compact motors are essential for miniaturized drones.

Example: A surgical robot might use a Disc Rotor BLDC Motor to power a precise, quiet tool for delicate procedures.

How to Choose the Right Type for Your Robotics Application

Selecting the right type of BLDC Motor depends on your robot’s specific needs:

Need High Speed? Go for an Inner Rotor BLDC Motor.

Need High Torque? An Outer Rotor BLDC Motor might be the best choice.

Working in Tight Spaces? Consider a Disc Rotor BLDC Motor.

By understanding the strengths of each type, you can narrow down your options and find the motor that will deliver the best performance for your robotics project.

In the next section, we’ll look at real-world examples of how BLDC Motors are used in robotics, giving you a clearer picture of how these motors perform in action.

Real-World Examples of BLDC Motors in Robotics

Understanding the theory behind Brushless DC Motors (BLDC Motors) is one thing, but seeing them in action is where things get really exciting. In this section, we’ll explore some real-world examples of how BLDC Motors are used in robotics. These examples will give you a clearer picture of how these motors perform in different applications and why they’re the go-to choice for engineers and designers.

1. Robotic Arms: Precision and Power

Robotic arms are a staple in industries like manufacturing, healthcare, and logistics. They need to perform tasks with high precision and consistent power, whether it’s assembling tiny electronics or lifting heavy components.

How BLDC Motors Help:

High Torque: BLDC Motors provide the strength needed to lift and manipulate heavy objects.

Precise Control: Electronic commutation allows for smooth, accurate movements, essential for tasks like welding or painting.

Example: In automotive manufacturing, robotic arms powered by BLDC Motors are used to assemble car parts with millimeter precision. These motors ensure that every movement is smooth and accurate, reducing errors and improving efficiency.

2. Drones: Speed and Stability

Drones are one of the most popular applications for BLDC Motors, and for good reason. Whether it’s capturing aerial footage or delivering packages, drones need to be fast, agile, and stable.

How BLDC Motors Help:

High Speed: BLDC Motors enable drones to achieve the high RPMs needed for takeoff and flight.

Lightweight Design: The compact size and low weight of BLDC Motors help keep drones light and efficient.

Smooth Operation: Electronic commutation ensures stable flight, even in windy conditions.

Example: Commercial drones used for aerial photography rely on BLDC Motors to provide smooth, stable flight, allowing for crystal-clear images and videos.

3. Autonomous Vehicles: Power and Durability

Autonomous vehicles, whether they’re self-driving cars or delivery robots, need to navigate a variety of terrains while carrying loads. This requires a motor that’s both powerful and durable.

How BLDC Motors Help:

High Torque: BLDC Motors provide the power needed to climb hills or navigate rough terrain.

Efficiency: The energy-efficient design of BLDC Motors helps extend battery life, crucial for long-distance travel.

Durability: With no brushes to wear out, BLDC Motors are built to last, even in demanding environments.

Example: Delivery robots used in warehouses or urban environments often use BLDC Motors to navigate tight spaces and carry heavy packages efficiently.

4. Medical Robots: Precision and Quiet Operation

In the medical field, robots are used for everything from surgery to diagnostics. These applications require extreme precision and quiet operation, as even the slightest error or noise can have serious consequences.

How BLDC Motors Help:

Precise Control: BLDC Motors allow for exact movements, essential for tasks like suturing or biopsy.

Low Noise: The quiet operation of BLDC Motors ensures a calm environment for both patients and medical staff.

Compact Size: The small size of BLDC Motors makes them ideal for integration into medical devices.

Example: Surgical robots used in minimally invasive procedures rely on BLDC Motors to perform delicate tasks with unparalleled accuracy and control.

5. Home Robots: Efficiency and Reliability

From robotic vacuum cleaners to lawn mowers, home robots are becoming increasingly popular. These devices need to be efficient, reliable, and quiet to fit seamlessly into everyday life.

How BLDC Motors Help:

Energy Efficiency: BLDC Motors help extend battery life, allowing home robots to operate longer on a single charge.

Low Noise: The quiet operation of BLDC Motors ensures that home robots don’t disturb daily activities.

Durability: With minimal maintenance required, BLDC Motors are perfect for devices that need to operate reliably over long periods.

Example: Robotic vacuum cleaners like the Roomba use BLDC Motors to navigate homes efficiently and quietly, making household chores a breeze.

Tips for Selecting the Right BLDC Motor

By now, you’ve learned about the key factors to consider when choosing a Brushless DC Motor (BLDC Motor) and seen how these motors perform in real-world robotics applications. But how do you actually go about selecting the right motor for your project? In this section, we’ll share some practical tips to help you make the best choice and ensure your robot performs at its peak.

1. Define Your Requirements Clearly

Before you start shopping for a motor, take the time to clearly define your project’s requirements. Ask yourself:

What is the primary task of my robot? (e.g., lifting, flying, navigating)

How much torque and speed do I need?

What are the size and weight constraints?

How much power can my robot’s battery or power supply provide?

Having a clear understanding of your needs will help you narrow down your options and avoid overspending on features you don’t need.

2. Consult with Manufacturers

Don’t hesitate to reach out to BLDC Motor manufacturers or suppliers. They can provide valuable insights and recommendations based on your specific application. Many manufacturers offer:

Custom Solutions: Tailored motors designed to meet your exact requirements.

Technical Support: Expert advice on motor selection, installation, and maintenance.

Testing Services: Some manufacturers allow you to test motors before making a purchase.

Tip: Look for manufacturers with a strong reputation in the robotics industry, as they’re more likely to understand your needs.

3. Test Before You Commit

If possible, test the motor in a real-world scenario before making a final decision. This can help you:

Verify that the motor meets your torque, speed, and power requirements.

Ensure the motor operates smoothly and quietly in your robot’s environment.

Identify any potential issues before they become costly problems.

Tip: Some manufacturers offer sample motors or demo units for testing purposes—take advantage of these opportunities.

4. Consider Future Needs

While it’s important to meet your current requirements, it’s also wise to plan for the future. Ask yourself:

Will my robot’s tasks become more demanding over time?

Could I benefit from a motor with higher torque or speed in the future?

Is there room for upgrades or modifications?

Choosing a motor that can grow with your project can save you time and money down the line.

5. Don’t Overlook Control Systems

A great motor is only as good as its control system. Make sure you have the right Electronic Speed Controller (ESC) and software to manage your BLDC Motor. Key considerations include:

Compatibility: Ensure the ESC is compatible with your motor’s voltage and current requirements.

Precision: Look for controllers that offer fine-tuned control over speed and torque.

Ease of Integration: Choose a control system that integrates seamlessly with your robot’s existing hardware and software.

Tip: Some BLDC Motors come with integrated controllers, which can simplify the setup process.

6. Budget Wisely

While it’s tempting to go for the most powerful or feature-rich motor, it’s important to balance performance with cost. Consider:

Total Cost of Ownership: Include factors like maintenance, energy consumption, and potential upgrades.

Value for Money: Sometimes a slightly more expensive motor can offer better long-term value due to its durability or efficiency.

Tip: Don’t sacrifice quality for cost—investing in a reliable motor can save you money in the long run by reducing downtime and maintenance.

7. Read Reviews and Case Studies

Finally, take the time to read reviews and case studies from other robotics enthusiasts and professionals. These can provide valuable insights into:

Real-World Performance: How the motor performs in actual robotics applications.

Common Issues: Any challenges or limitations you should be aware of.

Best Practices: Tips and tricks for getting the most out of your motor.

Tip: Look for reviews from users with similar applications to yours—this will give you the most relevant information.

Conclusion

Choosing the right Brushless DC Motor (BLDC Motor) for your robotics application is no small task, but it’s one of the most important decisions you’ll make in your project. From understanding the unique requirements of robotics to evaluating factors like torque, speed, size, and control, we’ve covered everything you need to know to make an informed choice.

Throughout this guide, we’ve explored:

The key factors to consider when selecting a BLDC Motor, including torque, speed, and power requirements.

The different types of BLDC Motors and how they cater to specific robotics applications.

Real-world examples of how BLDC Motors are used in robotics, from drones and robotic arms to medical devices and autonomous vehicles.

Practical tips for selecting the right motor, including consulting with manufacturers, testing before buying, and planning for future needs.

By now, you should have a clear understanding of how to choose the perfect BLDC Motor for your robotics project. Whether you’re building a high-speed drone, a precision surgical robot, or a heavy-duty autonomous vehicle, the right motor can make all the difference in achieving optimal performance and efficiency.

Take the Next Step

If you’re ready to take your robotics project to the next level, explore our range of BLDC Motors designed for robotics applications. Our motors are built to deliver high performance, reliability, and precision, ensuring your robot operates at its best.

For more information, visit our FAQ page or contact our team for personalized assistance. We’re here to help you find the perfect motor for your needs and bring your robotic vision to life.

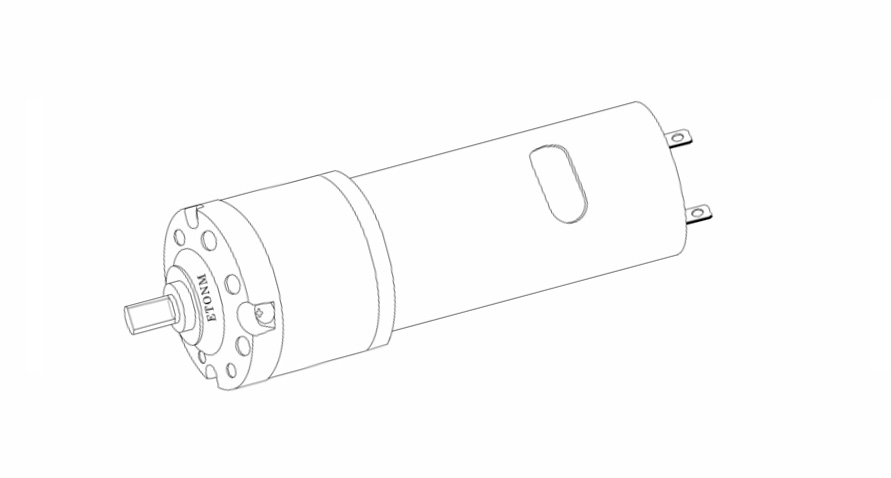

Motors for Robots Applications

Related Reading

- What is a Planetary Gear Motor?

- What is a Worm Gear Motor? The Ultimate Guide to Its Applications and Benefits

- Advantages of Planetary Gear Motors

- How to Choose the Right Curtain Motor: Key Factors and Expert Tips

- Technical Parameters and Customization of Low RPM Brushless Motors: A Comprehensive Guide

- BLDC Motor Vs Brushed Motor: Key Differences & Best Applications

- Top 5 Applications Of BLDC Motors In Industrial Automation

- Brushless DC Motors In Medical Devices | BLDC Motor Applications

- BLDC Motors In Electric Vehicles: Types, Benefits & Applications

- How To Choose A Brushless Gear Motor

- How to Choose the Right Planetary Gear Motor for Your Application

- What Are the Key Advantages of Brushless Motors?

- Brushless DC Motors: Applications In Smart Home, Medical & Robotics