Gear motors are a critical component in many mechanical systems, and proper maintenance is essential to ensure their optimal performance and longevity. Neglecting regular care can lead to decreased efficiency, increased wear and tear, and even motor failure. In this article, we’ll outline some key maintenance practices that will help you keep your gear motor running smoothly.

1. Keep the Environment Dry and Clean

One of the most crucial factors in maintaining a gear motor is ensuring that it operates in the right environment. A dry and clean space is essential for the motor to perform at its best. Dust, moisture, and contaminants can significantly affect the motor’s efficiency, including its output speed, torque, and overall functionality. Over time, exposure to humidity or dust can cause the internal components to wear out or malfunction.

Maintenance Tip:

Always aim to operate your gear motor in a dry, clean, and well-ventilated environment. Regularly inspect the area around the motor to ensure there are no sources of moisture or excessive dust that could interfere with its operation. Keeping the surrounding environment safe and clean is key to preventing premature damage.

2. Regular Cleaning to Prevent Build-up

Even if you keep the environment clean, gear motors are prone to dust and debris accumulation. Over time, this can obstruct airflow, overheat the motor, and increase wear on the components. Regular cleaning is therefore essential for ensuring the motor operates efficiently and without interruption.

Maintenance Tip:

Clean the surface of the gear motor regularly to remove dust, fibers, and other foreign materials. Pay special attention to the air intake area and ensure it remains unobstructed. A gentle cleaning with a soft brush or air blower can help maintain the motor’s optimal performance.

3. Conduct Periodic Inspections for Early Detection of Issues

One of the best ways to extend the lifespan of your gear motor is to conduct regular inspections. By checking for any signs of damage or malfunction early, you can address potential problems before they cause serious issues. For instance, if the motor’s thermal protection system activates frequently, it could indicate overheating or overload.

Maintenance Tip:

Perform periodic checks on the gear motor’s thermal protection system, bearings, and other critical components. Look for signs of wear such as unusual noise or vibration. If you notice anything abnormal, investigate the issue further to determine if it’s related to the motor itself, the load, or an incorrectly set protection value.

4. Replace Worn Components Timely to Avoid System Failure

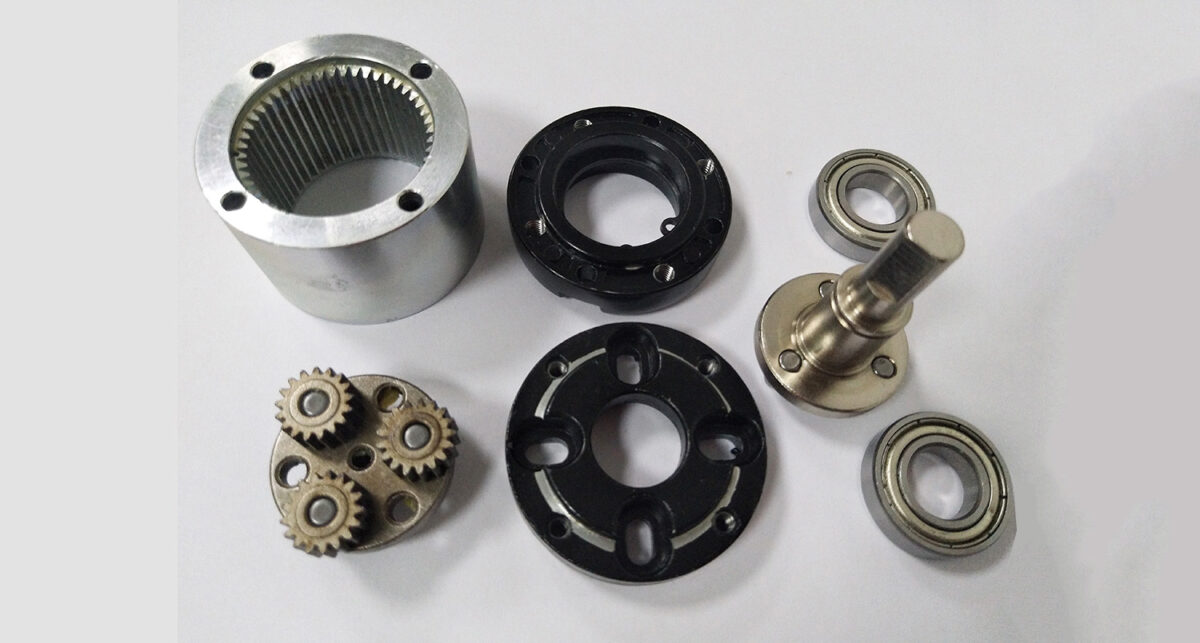

A gear motor typically consists of two main parts: the gearbox and the drive motor. The gearbox can be a planetary gearbox or a spur gearbox, which includes sun gears, planetary gears, and ring gears. The drive motor could be a DC motor, BLDC motor, or another type, with components like the stator, rotor, and bearings. Over time, some of these components will wear out, affecting the motor’s performance.

Maintenance Tip:

Monitor the condition of critical components, especially bearings. For example, when bearings near the end of their lifespan, they will produce more vibration and noise. If the radial clearance of the bearings exceeds specified limits, it’s time for a replacement. Regularly inspect and replace any components that show signs of wear to prevent further damage.

5. Lubrication: Keep It Running Smoothly

While not mentioned in your original draft, lubrication plays a critical role in reducing friction between moving parts in a gear motor. Proper lubrication ensures smooth operation, reduces wear and tear, and extends the life of the motor.

Maintenance Tip:

Check the lubrication levels regularly and ensure that the right type of lubricant is used for the specific motor and gearbox. Insufficient lubrication can lead to overheating, while excessive lubrication may cause buildup and contamination.

Conclusion

Regular maintenance is key to ensuring the longevity and performance of your gear motor. By keeping the environment clean, conducting regular inspections, replacing worn components, and maintaining proper lubrication, you can avoid costly repairs and ensure that your gear motor functions optimally for years to come. Following these simple yet effective practices will help you get the most out of your gear motor investment.