Struggling with a noisy DC motor? Discover practical ways to reduce DC motor noise with expert tips from Etonm Motor. From design tweaks to material choices, we’ve got you covered!

Table of Contents

Introduction

Let’s face it—there’s nothing worse than a DC motor humming away like a tiny chainsaw when you’re trying to enjoy a quiet smart home or keep a robot from sounding like it’s throwing a tantrum. Noise from DC motors isn’t just annoying; it can mess with the performance of devices like sanitary dispensers, vending machines, or even medical equipment where silence is golden. If you’ve ever wondered how to reduce DC motor noise without tearing your hair out, you’re in the right place.

Motor noise isn’t some unsolvable mystery—it’s a challenge we’ve tackled head-on at Etonm Motor. Whether it’s a whirring gear or a buzzing brush, there are practical ways to dial down the racket. In this post, we’re spilling the beans on why these motors get loud and sharing some real, actionable tips to keep them quiet. Stick with us, and you’ll see how a few smart tweaks can make all the difference—straight from the folks who live and breathe motor solutions.

Why Do DC Motors Make Noise?

Before you can hush up a noisy DC motor, it helps to know what’s causing all that commotion in the first place. Trust me, it’s not just the universe conspiring to ruin your peaceful project—there are real culprits behind the buzz, whir, and clatter. Let’s break it down into two big troublemakers: mechanical noise and electrical noise. Understanding these will set you up to tackle the problem like a pro.

1. Mechanical Noise Sources

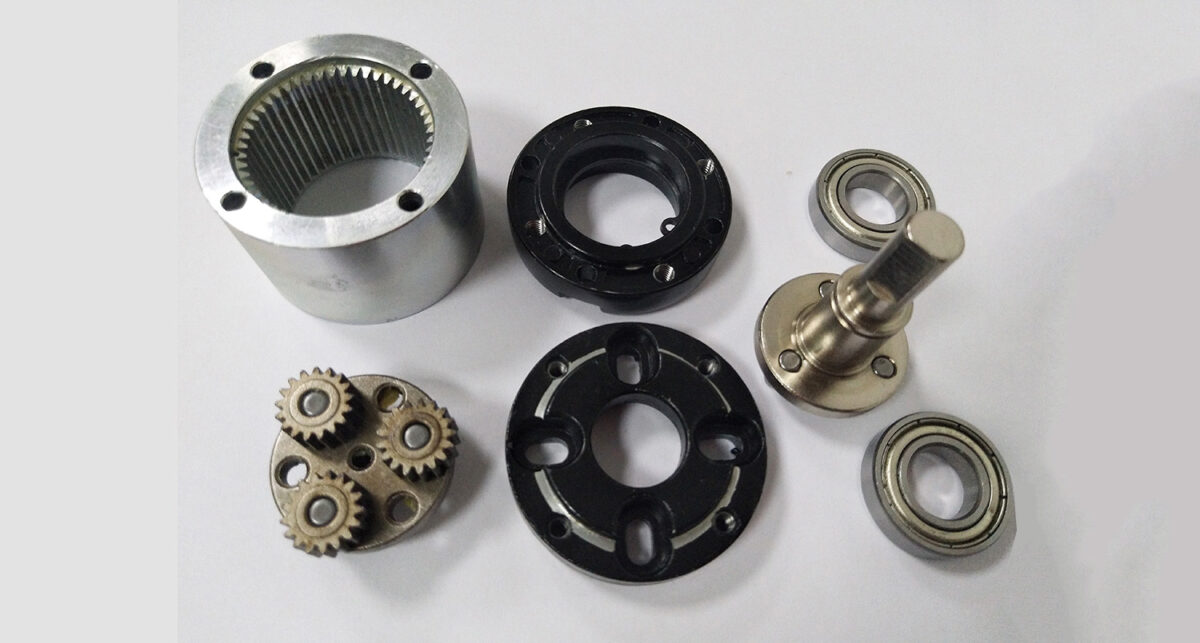

If your DC motor sounds like it’s grinding its teeth, chances are the mechanical bits are to blame. Worn-out bearings are a classic offender—think of them as the squeaky hinges of the motor world. Cheap or poorly maintained bearings can bump up noise levels by 20-30 decibels, which is enough to turn a quiet hum into a headache. Then there’s the gears. In motors with planetary or worm gear setups, sloppy tolerances or misaligned teeth can create a racket that echoes through your device. Vibration’s another sneaky player; an unbalanced rotor can shake things up—literally—and amplify the sound. At Etonm Motor, we’ve seen how tiny design flaws can snowball into big noise issues, especially in robotics or smart home gadgets where silence matters.

2. Electrical Noise Contributors

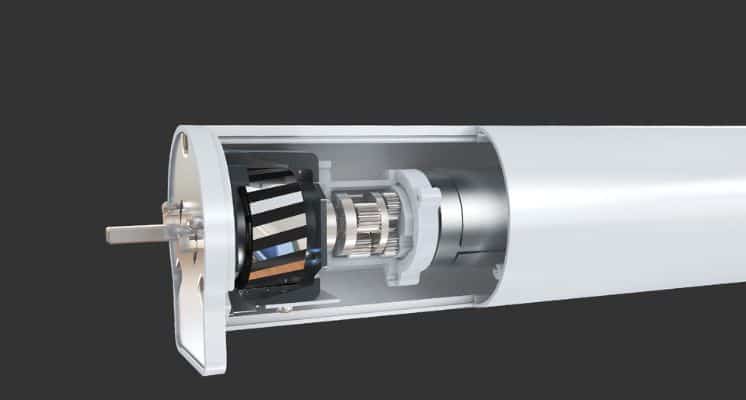

Now, let’s flip the switch to the electrical side. Ever heard that high-pitched whine that makes you wince? That’s often the brushes rubbing against the commutator, especially in brushed DC motors. It’s like nails on a chalkboard, but smaller and spinny. Electromagnetic interference (EMI) can also kick in, adding a buzzing undertone if the windings or power supply aren’t playing nice. Throw in a choppy voltage input, and you’ve got a recipe for what we call “vibration control headaches.” Brushless motors—like the ones we craft at Etonm Motor—cut down on this drama, but even they aren’t immune if the setup’s off. Bottom line? Electrical noise sneaks up when the juice isn’t flowing smoothly.

Practical Tips to Reduce DC Motor Noise

Okay, now that we’ve unmasked the noise culprits, let’s roll up our sleeves and get to fixing them. You don’t need a PhD in engineering to make your DC motor quieter—just some smart moves and a little know-how. Here are three practical ways to silence that whirring beast, whether it’s powering a vending machine or a robotic arm. Let’s dive in.

1. Optimize Motor Design for Silence

First up: the design itself. A motor’s guts—like its gears and rotor—can make or break its noise levels. Swap out clunky gears for something smoother, like a planetary gear setup, and you’ll notice the difference fast. These babies mesh better and cut down on that grinding chatter. At Etonm Motor, our planetary gear motors are built with low noise in mind—think tight tolerances and balanced rotors that don’t wobble like a drunk toddler. Even small tweaks, like adding a dampening layer to the casing, can hush things up. It’s not rocket science; it’s just designing with quiet in mind from the get-go.

2. Choose the Right Materials

Materials matter more than you’d think. Ever tried running a motor with bargain-bin bearings? It’s like putting squeaky sneakers on a mouse—noise city. Go for high-quality bearings (ball or sleeve, depending on your load) to smooth out the ride. Adding rubber mounts or vibration-damping pads between the motor and its housing is another winner; they soak up those pesky shakes before they turn into soundwaves. We’ve seen this work wonders in smart home devices, where quiet DC motor solutions are non-negotiable. Spend a little extra on the good stuff, and your ears will thank you.

3. Fine-Tune Operating Conditions

Sometimes, the fix isn’t in the hardware—it’s in how you run it. Overloading your motor or cranking the voltage too high can turn a soft hum into a full-on growl. Dial it back to the sweet spot with proper load matching, and you’re halfway there. Another trick? Use pulse-width modulation (PWM) to control speed—it smooths out the power delivery and cuts that electrical whine. If you’re still hearing buzz, swapping to a brushless DC motor might be your ace in the hole (check out our brushless motor lineup for some slick options). Fine-tuning isn’t glamorous, but it’s a game-changer for how to silence a DC motor without breaking the bank.

Testing and Measuring Noise Reduction

So, you’ve tweaked your motor—swapped the gears, upgraded the bearings, maybe even dialed down the voltage. But how do you know it’s actually quieter? Guessing won’t cut it; you need to test it and see the numbers for yourself. Measuring noise isn’t as intimidating as it sounds, and it’s the best way to prove your hard work paid off. Here’s how to check if you’ve really managed to reduce DC motor noise—or if you’re just imagining things.

Get Hands-On with a Decibel Meter

Grab a decibel meter (you can snag a decent one for under $30 online) and set it up near your motor—about a foot away works fine. Run the motor under its normal load and jot down the reading. A typical DC motor might hum along at 50-60 decibels, but if it’s screaming past 70, you’ve got work to do. After applying your noise-reduction tricks—like the ones we’ve talked about—test it again. Seeing that number drop by even 5-10 dB feels like a win, because every little bit counts when you’re chasing silence. Pro tip: test in a quiet room, or your neighbor’s lawnmower might throw off the vibe.

Why It Matters (and Where to Learn More)

Testing isn’t just for bragging rights—it’s how you dial in those low-noise DC motor designs we all dream of. If you’re curious about the nitty-gritty of noise standards, check out the IEEE’s guide on motor noise testing—it’s a gold mine for geeks who want to go deep. For the rest of us, a simple before-and-after check tells the story. Whether you’re building a security gadget or a medical device, knowing your motor’s noise level can make or break the project. At Etonm Motor, we’re obsessed with getting this right, because a quiet motor isn’t just nice—it’s a must for the stuff we make.

Conclusion

Noisy DC motors don’t have to be the soundtrack of your next project. By digging into why they hum—like those pesky mechanical rattles or electrical whines—you can take control. Optimize the design with slick gears, pick materials that hush the vibes, and tweak how it runs to keep things smooth. These DC motor noise reduction tips aren’t just theory; they’re practical steps to make your smart home device, robot, or valve whisper instead of roar.

At Etonm Motor, we’ve spent years perfecting quiet solutions because we know silence isn’t a luxury—it’s a necessity. Ready to put these ideas to work? Swing by our product page to explore motors built for low noise from the ground up, or contact us to chat about custom options. Your project deserves to run like a dream—quietly, of course.

Related Reading

- What is a DC Motor? A Simple Guide by Etonm Motor

- How Does a DC Motor Work? A Simple Guide by Etonm Motor

- Brushless DC Motor Manufacturers You Should Know

- What Determines the Speed of a Brushless DC Motor?

- Optimizing Brushless DC Motor Performance: The Role of Winding Configurations

- How Temperature Rise Affects Motor Performance and Lifespan

- What Is DC Motor Torque? A Simple Guide by Etonm Motor

- Exploring Performance Traits of Brushless DC Motors

- How to Increase Torque in Brushless DC Motors: A Practical Guide

- How Does a Brushless DC Motor Work? A Complete Guide to BLDC Motors

- Brushless DC Motor Troubleshooting: Common Issues and Solutions

- What Factors Affect the Performance of Brushless Motors? A Comprehensive Guide

- 12V DC Motor High Torque Low RPM Performance

- Comprehensive Guide to Low-Noise Gear Motors: Features, Types, and Applications