"Curious about low RPM motors? Learn what they are, how they deliver high torque, and their applications in robotics, smart homes, and more with Etonm Motor."

Table of Contents

Introduction

Motors power much of the world around us, but not all are built for speed. A low RPM motor stands out by focusing on torque—delivering steady, powerful motion at reduced revolutions per minute. These high torque low rpm motors are increasingly vital in an era where precision and efficiency drive innovation. Whether it’s a robotic arm lifting a load or a smart curtain gliding open, low rpm electric motors provide the backbone for countless applications. At Etonm Motor, we’ve seen demand grow for these motors in fields like sanitary dispensers, vending machines, and medical equipment, reflecting their versatility. What makes them so essential, and how do they work? This guide dives into their mechanics, benefits, and real-world uses to answer those questions.

What is a Low RPM Motor?

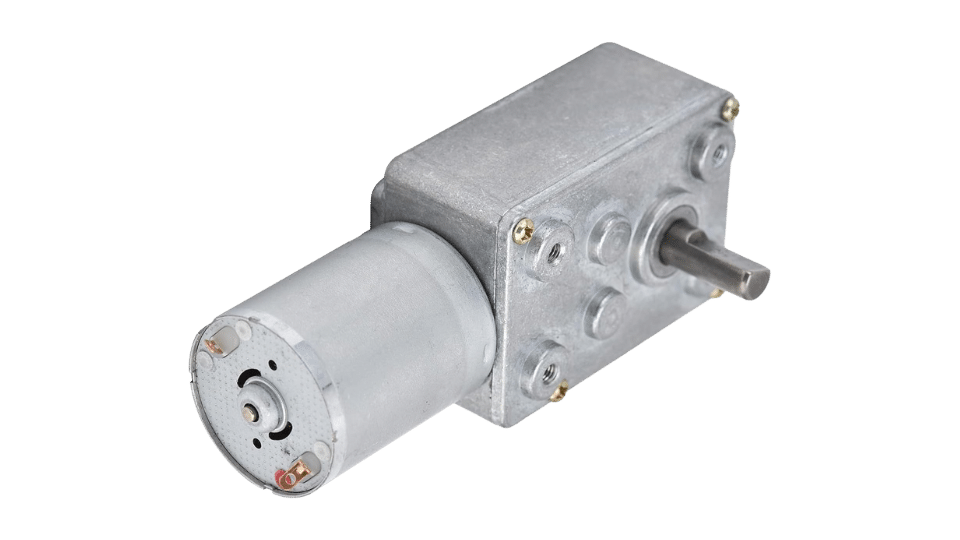

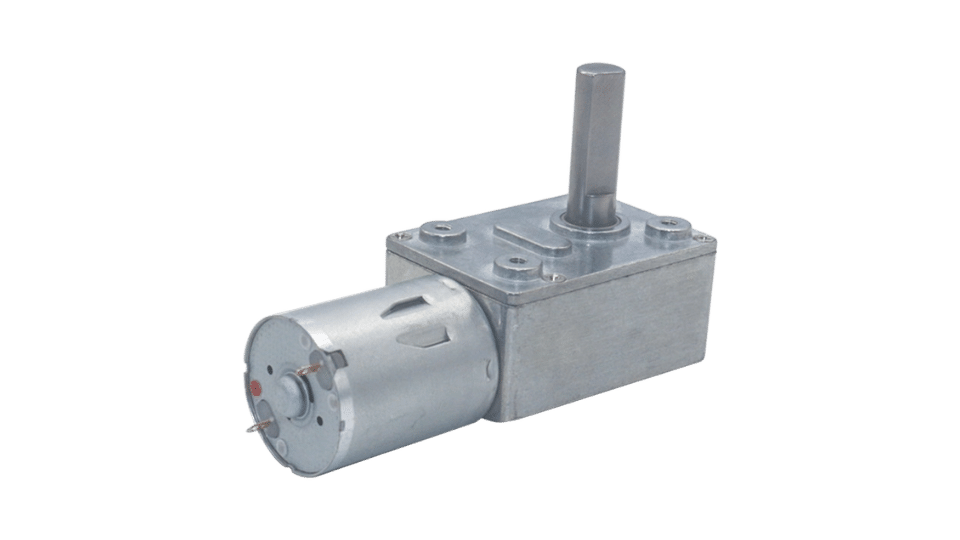

A low RPM motor operates at low revolutions per minute—typically below 1000 RPM—prioritizing torque over speed. Unlike high-speed motors, which excel in tasks like powering fans or drills, a low rpm electric motor is designed for applications needing controlled, forceful motion. This distinction is key: while a high-speed motor might spin at 10,000 RPM with minimal torque, a high torque low rpm motor delivers strength at a fraction of that speed. Many achieve this through gear systems like planetary or worm gears, reducing output speed while amplifying torque. For example, a 12v dc motor high torque low rpm can steadily drive heavy loads, making it a staple in automation. At Etonm Motor, our motor high torque low rpm designs—like the Flat Gearbox Motor—cater to needs ranging from robotics to electric valves, offering tailored power solutions.

How Does a Low RPM Electric Motor Work?

A low-RPM electric motor transforms electrical energy into mechanical motion at reduced speeds, emphasizing torque output. This is enabled by gear reduction systems—such as planetary gears, worm gears, or flat gearboxes—that lower rotational speed while boosting force. In a high torque low rpm electric motor, the rotor generates motion, which the gears then refine. For instance, a gear ratio of 20:1 can reduce speed from 2000 RPM to 100 RPM while increasing torque twentyfold. A 12v dc motor high torque low rpm leverages this principle, using moderate voltage to deliver consistent performance under load. At Etonm Motor, our electric motor low rpm offerings, like the Worm Gear Motor, are fine-tuned for efficiency—achieving up to 85% power transmission in some designs. This makes them reliable for robotics, metering devices, and other precision-driven systems.

Benefits of Using a High Torque Low RPM Motor

A high torque low rpm motor brings distinct advantages to specialized applications. Its standout feature is delivering significant torque at low speeds, ideal for heavy loads or precise tasks. In robotics, a motor high torque low rpm can lift 5-10 kg with ease, far surpassing high-speed alternatives. Energy efficiency is another perk: by minimizing friction and heat, a low rpm electric motor can reduce power use by 20-30% compared to high-RPM models, per industry studies. This efficiency also cuts noise and vibration, making a 12v dc motor high torque low rpm perfect for quiet settings like smart homes—think automated blinds operating at under 40 decibels. Durability rounds out the benefits, as lower speeds reduce wear, often extending motor life by 50% or more. Etonm Motor’s high torque low rpm electric motors, like our Brushless Motor, deliver these gains in security systems and vending machines, proving their worth in demanding environments.

Applications of Low RPM Motors in Everyday Life

Low RPM motors are woven into daily life, powering devices that demand precision and strength. In smart homes, a low rpm electric motor drives automated curtains or soap dispensers, offering smooth operation—Etonm’s Micro DC Motor, for instance, powers units dispensing 1-2 ml with pinpoint accuracy. Robotics relies on a high torque low rpm motor for tasks like assembling parts or navigating obstacles, where torque up to 15 Nm ensures stability. Vending machines use a 12v dc motor high torque low rpm to dispense snacks or drinks, handling loads up to 3 kg without faltering. In medical care, high torque low rpm electric motors support infusion pumps, delivering fluids at rates as low as 0.1 ml/hour. Etonm Motor’s electric motor low rpm solutions—like the Round Gear Motor—also enhance security locks and metering valves, showcasing their adaptability across residential, industrial, and healthcare settings.

Choosing the Right Low RPM Motor for Your Needs

Picking the right low RPM motor hinges on matching its specs to your application. First, assess torque needs: a high torque low rpm motor suits heavy-duty tasks—say, a robotic arm needing 10 Nm—while a 12v dc motor high torque low rpm fits smaller, forceful systems like dispensers requiring 2-3 Nm. Voltage is next: a low rpm electric motor might run on 12V for portable devices or 24V for industrial use—ensure compatibility with your power source to avoid efficiency losses. Motor type matters too: a motor high torque low rpm with planetary gears offers rugged durability, while a brushless high torque low rpm electric motor cuts maintenance for long-term applications like medical tools. Finally, consider the environment—quiet electric motor low rpm designs for homes versus precision models for automation. Etonm Motor’s includes options like the Planetary Gear Motor—reach out to our team for expert advice on your project.

Conclusion

Low RPM motors are engineering workhorses, merging power, precision, and efficiency. From high torque low rpm motors in robotics to 12v dc motor high torque low rpm units in smart devices, their low-speed strength supports industries like medical care and security. By grasping their mechanics, benefits, and uses, you can confidently select the right high torque low rpm electric motor for your needs. At Etonm Motor, we’re committed to delivering customized motor high torque low rpm solutions that enhance performance. Dive deeper into our or contact us today to explore how our electric motor low rpm designs can power your next innovation.

Related Reading

- 12V DC Motor Low RPM: Precision Power by Etonm Motor

- 5 RPM to 3000 RPM: Mastering 12V Motor Speeds

- How to Choose a 12V DC Motor by RPM: Your Complete Guide

- 1000 RPM and Beyond: High Performance 12V DC Motors

- 12V DC Motor High Torque High RPM: Torque vs. Speed

- Low RPM Brushless Motor: Technical Specs & Customization

- 12V DC Motor High Torque Low RPM Performance

- Technical Parameters and Customization of Low RPM Brushless Motors: A Comprehensive Guide

- What is Electronic Speed Control (ESC) for Brushless DC Motors?

- Power Up Precision: High-Speed Brushless DC Motors for Screwdrivers

- BLDC Motor Speed Control: Methods, Tips & Applications

- Low Speed, High Torque: Why 12V Motors Are Perfect for Your DIY Projects

- DC Motor Speed Controller 12V Basics: From Brushed to BLDC

- Custom Control: Pairing 12V DC Motors with Speed and Encoder Accessories

- 12V DC Motor Speed Controllers: How They Work & Setup Tips

- What Determines the Speed of a Brushless DC Motor?