Curious about the differences between outrunner and inrunner Brushless DC Motors? This post breaks down their designs, performance, and ideal applications to help you pick the perfect BLDC for your project.

Table of Contents

Introduction

What Are Outrunner and Inrunner Brushless Motors?

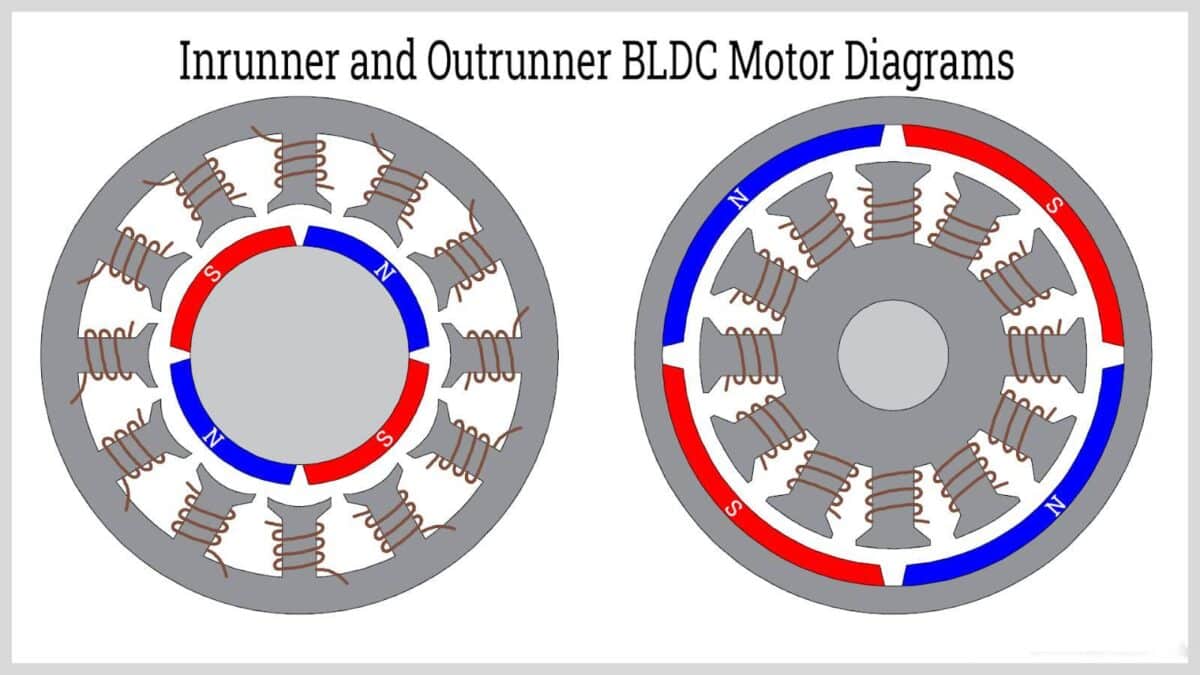

Let’s start with the basics—because even if you’re a motor geek, it’s good to get our bearings. A Brushless Motor, or BLDC for short, ditches the old-school brushes for electronic controls, making it efficient and low-maintenance. Now, within this family, you’ve got two cousins: the Outrunner Brushless Motor and the Inrunner Brushless Motor. The big difference? It’s all about where the spinning part—the rotor—sits.

In an outrunner, the rotor’s on the outside, spinning around a stationary core (the stator) tucked inside. Picture a ceiling fan blade whirling around its hub—that’s the vibe. It’s built for high torque, perfect for stuff like robotic joints that need serious muscle. On the flip side, the inrunner flips the script: the rotor spins inside a fixed outer shell (the stator). Think of a high-speed drill buzzing away—it’s compact and loves to rev up fast. So, whether you’re designing a fan or a zippy tool, knowing these layouts is your first step to picking the right Brushless DC Motor.

How Design Impacts Brushless DC Motor Performance

Now that we’ve got the basics down, let’s talk about why the design of a Brushless DC Motor matters so much—it’s not just about looking cool under the hood. The placement of the rotor in an outrunner versus an inrunner directly shapes how the motor performs, from speed to torque to how well it keeps its cool. Here’s the scoop.

With an Outrunner Brushless Motor, that outer rotor gives it a wider diameter, which is like adding extra leverage to a wrench—it pumps out serious torque at lower speeds, usually in the 200-400 RPM range. That makes it a champ for heavy-lifting tasks, like powering a drone’s propellers or a vending machine’s gears. Plus, since the spinning part is exposed, it sheds heat like a pro, keeping things running smoothly. On the other hand, an Inrunner Brushless Motor keeps its rotor tucked inside, spinning fast—think 1000+ RPM—and trading torque for speed. It’s sleeker and loves tight spaces, but it can get toasty if you push it too hard without good ventilation. So, when you’re tweaking your next BLDC design, ask yourself: do you need power or pace?

Applications: Where Each Brushless Motor Shines

So, you’ve got the rundown on how outrunners and inrunners work—now let’s see them in action. The beauty of a Brushless DC Motor is how it adapts to different jobs, and picking the right type can save you a headache down the line. Here’s where each BLDC really flexes its muscles.

Outrunner Brushless Motors are the go-to when you need raw power over speed. Think robotic arms twisting heavy loads, drone propellers slicing through the air, or vending machines quietly dispensing snacks—these motors thrive in applications demanding high torque. Their chunky design fits perfectly in setups where space isn’t a squeeze like Etonm Motor’s Brushless Motor lineup. Meanwhile, Inrunner Brushless Motors are the speed demons, shining in precision gigs like electric drills, smart home valves, or even medical pumps where fast, compact performance is king. Next time you’re prototyping a BLDC robotics project or tweaking a smart home motor, match the motor to the mission—it’s that simple.

Choosing the Right BLDC: Practical Tips

Alright, we’ve covered the what, the how, and the where—now it’s time to get down to brass tacks: how do you pick the perfect Brushless DC Motor for your project? Whether you’re building a slick robotics setup or fine-tuning a smart home gadget, a few practical pointers can steer you clear of guesswork. Let’s break it down.

First up, think about your load. If you’re moving something heavy—like a robotic arm hauling parts or a vending machine chute dropping cans—an Outrunner Brushless Motor is your best bet. Its high-torque design handles those beefy tasks without breaking a sweat. But if your gig is all about speed and precision, say a zippy electric screwdriver or a tiny valve in a water meter, go for an Inrunner Brushless Motor. It’s built to spin fast and fit snugly into tight spots. I’ve seen folks waste hours tweaking an inrunner for torque when an outrunner would’ve nailed it—don’t make that rookie move.

Next, check your space and cooling setup. Outrunners are chunkier and love open air to dump heat, which is great for drones buzzing outdoors but less ideal in a cramped enclosure. Inrunners, being slimmer, slide into compact designs like a charm, though they’ll need a solid plan to stay cool under pressure—think fans or heat sinks if you’re pushing them hard. A buddy of mine once fried an inrunner in a medical pump prototype because he skipped the ventilation step. Lesson learned: match the motor to your real-world conditions.

Finally, don’t go it alone if you’re stumped. Motors aren’t one-size-fits-all, and a custom tweak can make all the difference. Companies like Etonm Motor specialize in tailoring Brushless DC Motors to your specs—whether it’s tweaking torque for a robotics joint or dialing up RPMs for a sanitary dispenser. Drop them a line, sketch out your needs, and save yourself the trial-and-error headache. Picking the right BLDC isn’t rocket science, but a little know-how goes a long way.

Conclusion

So, there you have it—a crash course on outrunner versus inrunner Brushless DC Motors that’s hopefully cleared the fog. Whether you’re leaning toward the torque-heavy punch of an outrunner or the speedy zip of an inrunner, the right Brushless Motor choice can seriously level up your project—be it a robotic arm, a smart home gizmo, or something totally out of left field. It’s all about matching the motor to your mission, and now you’ve got the tools to do it.

What’s next? If you’re itching to put this into practice, why not sketch out your needs and bounce them off a pro? Companies like Etonm Motor can fine-tune a BLDC to fit your wildest ideas—check out their lineup for some inspiration.

Related Reading

- Brushless DC Motor vs. Servo Motor: What’s the Difference?

- How to Increase Torque in Brushless DC Motors: A Practical Guide

- BLDC Motor Speed Control: Methods, Tips & Applications

- Why Hall Sensors Are Essential in BLDC Motors

- How to Install a Brushless DC Motor: Expert Step-by-Step Guide

- How Does a Brushless DC Motor Work? A Complete Guide to BLDC Motors

- What is KV Rating in Brushless Motors and How to Calculate It?

- Brushless DC Motor Troubleshooting: Common Issues and Solutions

- Why Use a DC Motor Controller for BLDC Motor?

- What are the Components of Brushless DC Motor? A Comprehensive Guide

- What Factors Affect the Performance of Brushless Motors? A Comprehensive Guide

- AC Motors vs DC Motors: Which is Best for Your Application?

- Top 5 Applications of Brushless DC Motors in Industrial Automation

- BLDC Motor vs Brushed Motor: Which is Better for Your Needs?

- Technical Parameters and Customization of Low RPM Brushless Motors: A Comprehensive Guide