Curious about how a planetary gearbox works? This guide breaks it down with simple explanations, real-world examples, and insider tips from Etonm Motor—your go-to for custom motor solutions.

Table of Contents

Introduction

Ever wondered what powers your robotic vacuum to glide around corners with such precision—or how that smart lock on your door clicks into place so smoothly? Chances are, there’s a little engineering marvel called a planetary gearbox working behind the scenes. These compact powerhouses are everywhere, quietly driving the devices we rely on daily, from home gadgets to high-tech robotics. If you’re curious about how they tick (or spin, really), you’re in the right place—this guide’s got you covered.

At its core, a planetary gearbox is a clever system of gears that delivers big performance in a small package. It’s the kind of thing that sounds complicated but makes perfect sense once you break it down. And trust me, it’s worth understanding—not just for gearheads, but for anyone who loves seeing smart design in action. Here at Etonm Motor, we’ve been crafting these beauties for years, tailoring them to everything from medical tools to vending machines. So, let’s pop the hood and explore how a planetary gearbox works—spoiler: it’s cooler than you might think!

What Is a Planetary Gearbox?

So, what exactly is a planetary gearbox? Picture a tiny solar system spinning inside your device—that’s the vibe. It’s a gear setup where everything revolves around a central “sun gear,” surrounded by smaller “planet gears” that roll inside an outer “ring gear.” These pieces work together like a well-rehearsed dance troupe, all held in place by a carrier that keeps the chaos organized. The result? A compact, efficient way to transfer power that’s tougher than it looks.

What makes this design stand out is how it packs so much punch into a small space. Unlike clunky traditional gears, the planetary gear motor design spreads the load across multiple gears, making it a champ at handling stress. It’s why you’ll find these in everything from smart home gadgets to industrial robots. Honestly, it’s the kind of clever engineering that makes you wonder, “Why didn’t someone think of this sooner?”—except they did, and it’s been a game-changer ever since.

How Does a Planetary Gearbox Work?

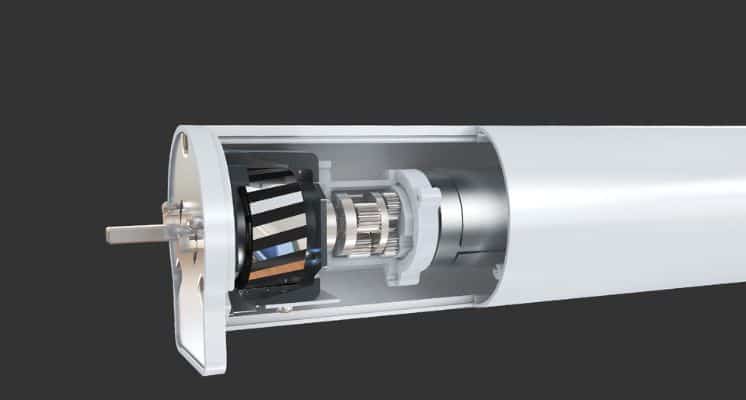

Okay, let’s get to the good stuff: how does a planetary gearbox work? It’s simpler than it sounds, but still pretty impressive. Imagine the sun gear in the center spinning like a fidget spinner on caffeine. That motion gets picked up by the planet gears circling around it—they’re meshed with both the sun gear and the outer ring gear, so they roll along like little moons. The carrier ties them all together, turning their teamwork into usable power at the output shaft.

Here’s where it gets cool: because the load is shared across multiple planet gears, you get smooth, efficient power delivery—often up to 90% efficiency, which is nuts for something so small. Whether it’s cranking up torque for a robotic arm or slowing things down for precise control in a smart dispenser, the planetary gearbox adapts like a pro. It’s less about brute force and more about clever coordination—engineering at its finest!

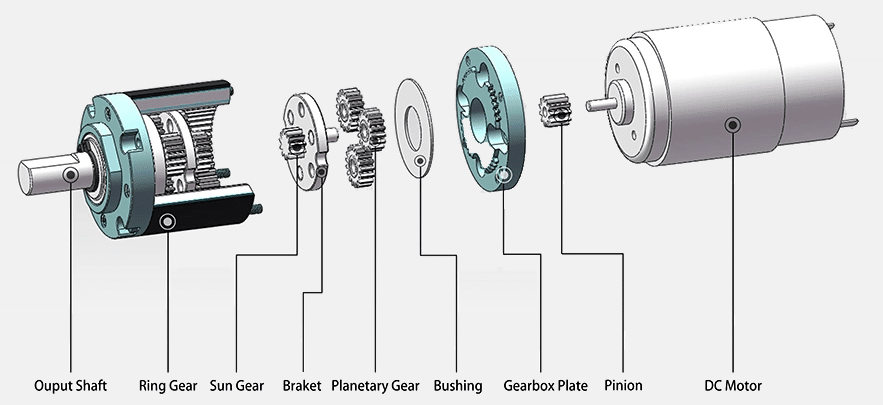

Key Components of a Planetary Gearbox

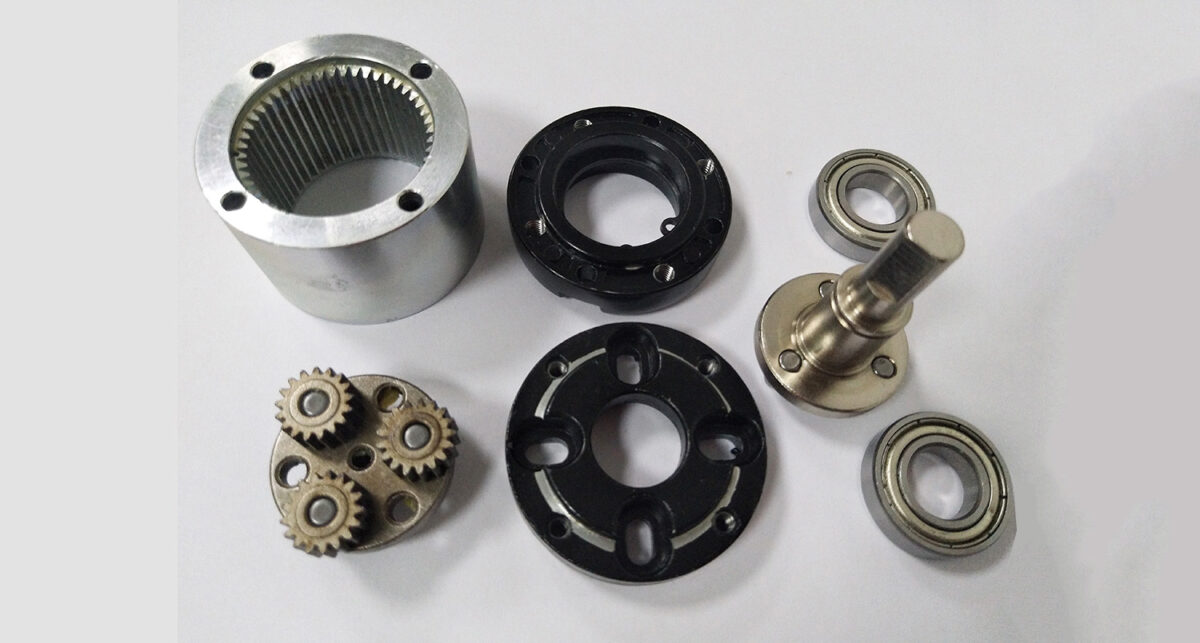

To really get how a planetary gearbox ticks, let’s meet the star players. First up, the sun gear—this little guy sits in the middle, kicking things off by spinning fast and passing energy to the next in line. Surrounding it are the planet gears, usually three or four of them, rolling around like backup dancers sharing the workload. They’re held together by the carrier, the unsung hero that keeps everything moving in sync and delivers the final output. Then there’s the ring gear, the outer rim with teeth inside, locking it all into place.

This setup is what makes compact gear motor technology so brilliant. Each part plays its role without hogging space, turning a small gearbox into a powerhouse. Whether it’s powering a medical pump or a security lock, these components are the secret sauce behind the magic. Pretty neat, right?

Benefits of Using a Planetary Gearbox

Why go with a planetary gearbox? Well, it’s kind of a no-brainer once you see what it brings to the table. For starters, it’s a torque beast—thanks to those planet gears sharing the load, it can handle up to three times more torque than a basic spur gear setup. That’s huge for things like robotics or heavy-duty valves. Plus, it’s compact. You get all that power crammed into a tiny package, perfect for sleek smart home gadgets or tight spaces in machinery.

Then there’s durability. The design spreads stress evenly, so it lasts longer than you’d expect—think years, not months. Efficiency’s another win; these babies often hit 90% or higher, according to gear experts at Machine Design. The planetary gear system benefits shine in real life: smoother operation, less wear, and versatility that’s tough to beat. Honestly, it’s like the Swiss Army knife of gearboxes!

Planetary Gearbox Applications in Real Life

So, where does a planetary gearbox show up in the wild? Pretty much anywhere you need power and precision in a small space. Take robotics—those nimble arms assembling gadgets or picking packages rely on these gearboxes for smooth, strong movement. In smart homes, they’re the muscle behind automated blinds or that fancy soap dispenser that never jams. Even vending machines use them to crank out snacks without a hitch.

I’ve seen them in action in some cool places, too—like hospital beds that adjust quietly or water meters that run like clockwork. These planetary gearbox applications are why we at Etonm Motor love what we do. Want to dig deeper into how we customize them? Check out our Planetary Gear Motor page. It’s wild how something so small can power such big ideas, isn’t it?

Planetary Gearbox vs Other Gearboxes

How does a planetary gearbox stack up against the competition? Let’s put it in the ring with a couple of classics. Take worm gears—they’re great for slow, steady jobs and self-locking tricks, but they can’t touch the efficiency or speed of a planetary setup. Spur gears? Super simple and cheap, but they’re noisy and buckle under heavy loads, while a planetary gearbox just shrugs it off with its multi-gear teamwork.

The real knockout punch is versatility. With planetary gearbox vs other gearboxes, you’re looking at a champ that delivers high-torque gearbox solutions in a compact frame—something worm and spur can only dream of. Worm gears are cool for niche stuff, but they’re not winning any agility awards. Planetary’s the all-rounder—quiet, tough, and ready for anything. It’s like picking a sports car over a tractor, depending on what you need!

Conclusion

There you have it—a planetary gearbox isn’t just a bunch of gears spinning around; it’s a smart, compact powerhouse that makes modern life tick. From the way it divvies up torque with those planet gears to its knack for fitting into tight spaces, it’s a design that punches way above its weight. Whether you’re talking robotics, smart homes, or even that vending machine down the hall, this little marvel keeps things moving smoothly and reliably.

At Etonm Motor, we’re all about turning that clever engineering into solutions that work for you. Want to see these gearboxes in action or dream up a custom fit for your next project? Swing by our custom motor solutions page or drop us a line—we’d love to chat. After all, who doesn’t love a good gear story?

Related Reading

- How Does a DC Motor Work? A Simple Guide by Etonm Motor

- Brushless DC Motor Manufacturers You Should Know

- What Is a Gear Motor? Benefits and Uses by Etonm Motor

- What is Electronic Speed Control (ESC) for Brushless DC Motors?

- How to Choose the Right Planetary Gear Motor for Your Application

- How to Choose the Right Brushless Gear Motor for Your Application

- How Do BLDC Worm Gear Motors Work? A Complete Guide

- What is a BLDC Worm Gear Motor? A Comprehensive Guide for 2025

- What is a Worm Gear Motor? The Ultimate Guide to Its Applications and Benefits

- Advantages of Planetary Gear Motors

- Introduction of Planetary Gear Motor for Robot