What Are Low-Noise Gear Motors?

Low-noise gear motors are designed to minimize noise during operation, with noise levels typically under 45 dB. These micro-drive gear motors combine small power and advanced technology to ensure quiet and efficient performance. At ETONM, we specialize in providing low-noise electric motors tailored to meet specific application needs.

The drive source of these motors can include DC motors and micro motors, while the reduction mechanism can feature planetary gearheads, cylindrical gearheads, or worm gearheads. ETONM’s low-noise gear motors are known for their reliability, performance, and extensive customization options, making them ideal for various industries.

Types of Low-Noise Gear Motors Based on Gearbox Structure

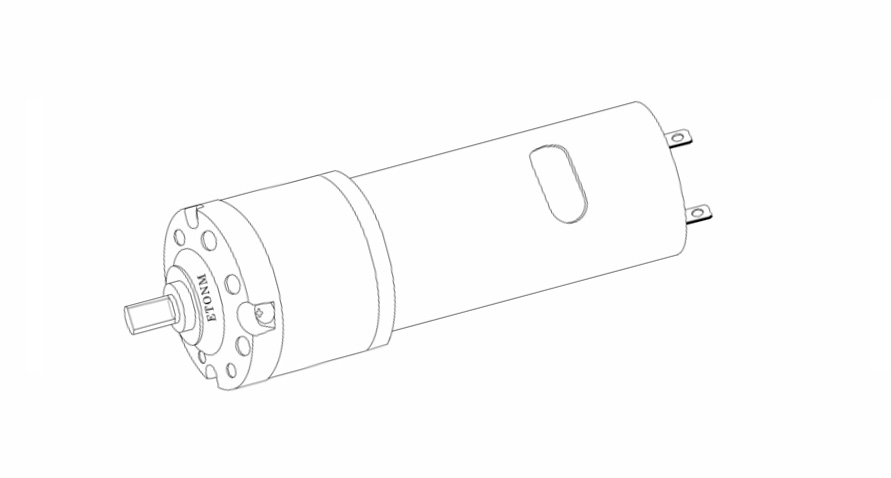

1. Coaxial Gear Motors

The coaxial micro helical gear motor offers a compact structure, small size, and strong overload capacity. Key features include:

- High Efficiency: Up to 96%, ensuring optimal energy utilization.

- Low Vibration and Noise: Perfect for environments requiring quiet operation.

- Durability: Strong adaptability for corrosive, humid, or harsh environments.

- Versatility: Easy to maintain with low operational costs.

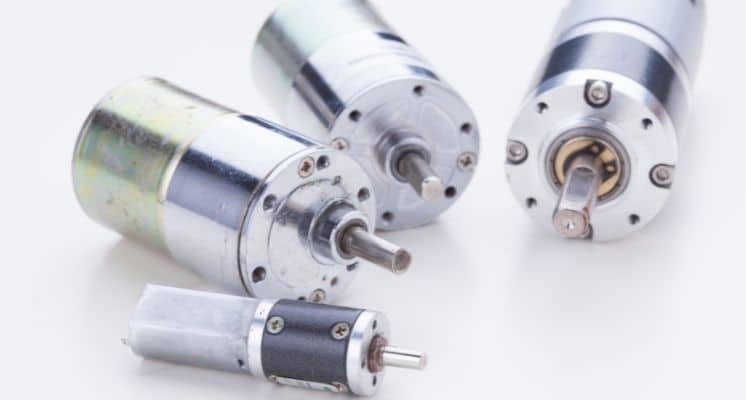

2. Two-Stage Cylindrical Gear Motors

These motors are categorized into high-speed and low-speed variants:

- High-Speed Gear Motors: Superior performance when shunted, suitable for rapid applications.

- Low-Speed Gear Motors: Even load distribution with symmetric gear arrangement for enhanced durability.

The coaxial installation mode ensures a compact radial dimension, although the axial dimension might increase, requiring precise engineering to mitigate load concentration and axis bending under heavy loads.

Key Features of Low-Noise Gear Motors

ETONM’s low-noise gear motors deliver several advantages:

- Low Noise: Ensuring quieter operations ideal for noise-sensitive environments.

- Lightweight and Compact Design: Easy to integrate into various applications.

- High Carrying Capacity: Capable of handling significant loads.

- Long Service Life: Durable construction for extended usage.

- High Transmission Precision: Ideal for applications requiring accuracy and stability.

Applications of Low-Noise Gear Motors

Thanks to their versatile design and reliable performance, low-noise gear motors are extensively used in:

- Robotics: Ensuring precise movement and quiet operation.

- Medical Equipment: Reliable performance in sensitive environments.

- Smart Home Devices: Including electric curtains, intelligent locks, and solar automation.

- Sanitary Dispensers and Intelligent Cleaners: Offering smooth and silent functionality.

- Banking and Vending Automation: Ensuring efficiency and low maintenance.

- Beauty and Healthcare Devices: Providing stable performance for advanced devices.

- Explore more applications of low-noise gear motors

Why Choose ETONM for Low-Noise Gear Motors?

ETONM’s commitment to innovation and precision ensures that every low-noise gear motor meets high industry standards. We provide:

- Customizable Parameters: Including dimensions, reduction ratios, and torque capacity.

- Advanced Engineering: Leveraging cutting-edge technology to enhance performance.

- Dedicated Support: From design to assembly, ensuring seamless integration into your projects.

Related Reading

- Advantages of Planetary Gear Motors

- How to Calculate Transmission Gear Ratio: A Comprehensive Guide for Gear Systems

- 12V DC Motor High Torque Low RPM Performance

- How to Choose the Right Curtain Motor: Key Factors and Expert Tips

- Introduction of Planetary Gear Motor for Robot

- Introduction of 12V DC Micro Motor Products

- Technical Parameters and Customization of Low RPM Brushless Motors: A Comprehensive Guide

- Why Choose 24v Small DC Motors?