ET-CGM95G

12V 100 RPM DC Geared Motor for Needle Valve Control - Reliable Power for Precision Applications

12V, 100 RPM geared motor for precise and reliable needle valve control in fluid regulation systems, ideal for industrial, HVAC, and custom applications.

We offer Customization services:

- Output shaft dimension

- Dc motor

- Voltage

- Speed

- Torque

- Current

- Lifetime

- Noise

Precision 12V 100 RPM DC Geared Motor for Needle Valve Control

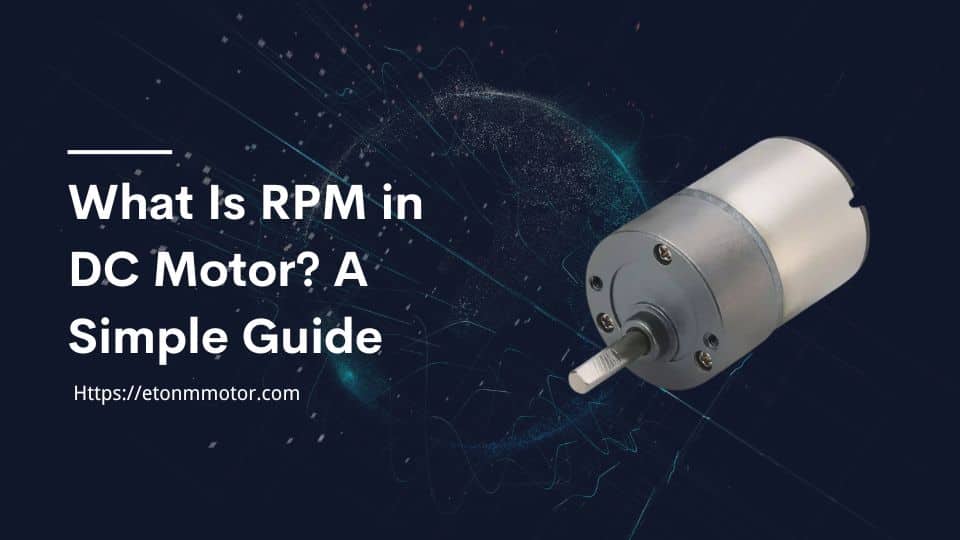

The 12V 100 RPM DC Geared Motor is designed for precision and reliability, making it an ideal choice for needle valve control in fluid regulation systems. With its low speed and high torque output, this motor ensures smooth, accurate operation, making it suitable for applications in HVAC systems, medical equipment, and industrial control systems. Customizable with various gear ratios, shaft types, and voltage options, it can be tailored to meet your specific needs. Explore our DC geared motor collection or contact us for custom solutions.

Custom DC Gearmotors for Your Needs

Performance Range

- Voltage: 6-24vdc

- Speed: 1-170rpm

- Torque: 1-50kg.cm

Key Features

- High Torque Small Size

- Large Speed Range

- CW/CCW Running

Typical Applications

- Home Appliances

- Banking and Vending System

- Electric Valve and Robotics

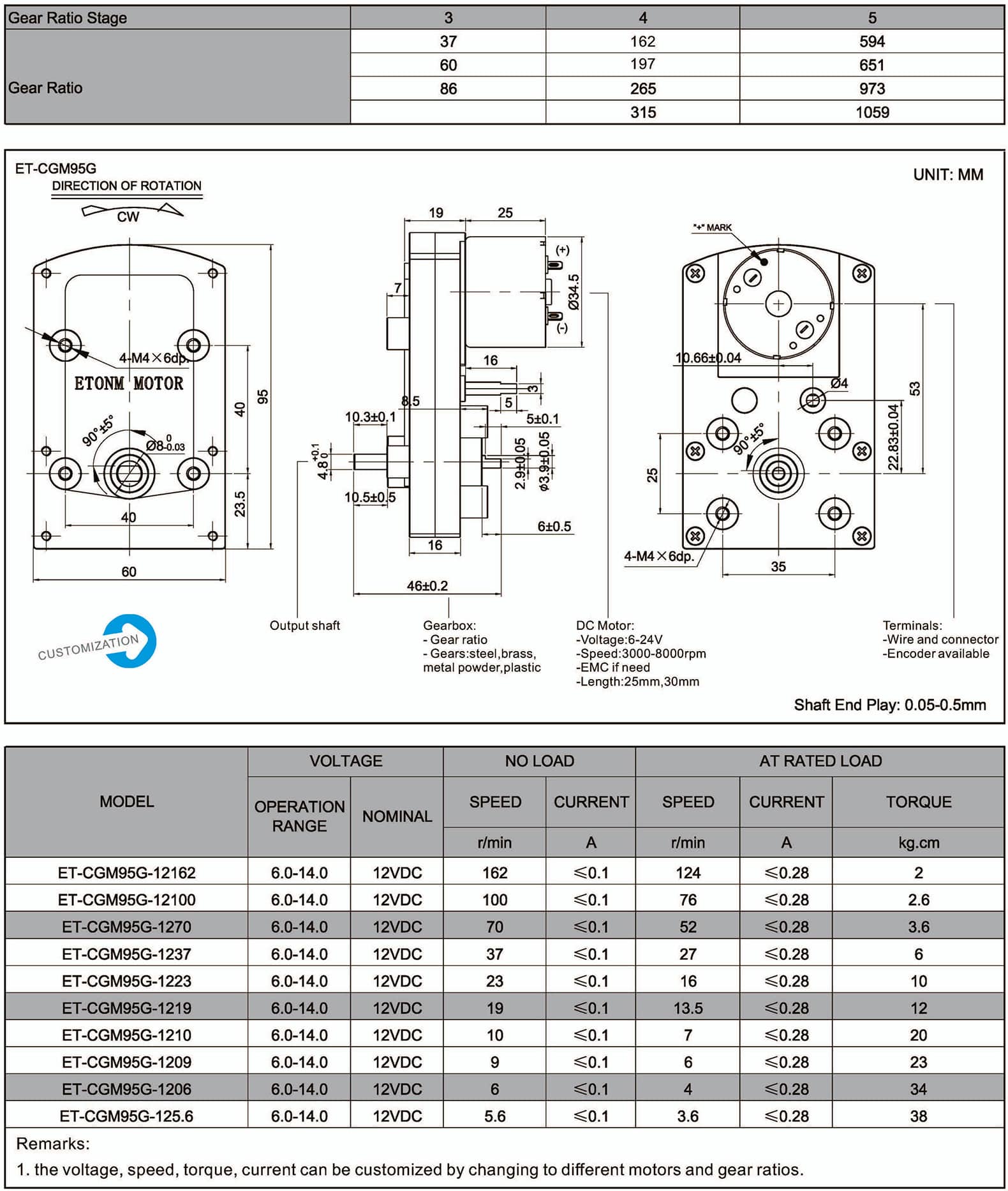

Technical Specifications and Custom Options

Need a Custom DC Geared Motor for Needle Valve Control?

Innovative Motor Solutions for Diverse Applications

ETONM MOTOR’s Mini DC Motors and Gear Motors are designed to meet the needs of a wide range of industries. Our motors provide reliable performance and precision across numerous applications, helping businesses power their projects efficiently and innovate.

Related Motors

FAQs

A needle valve motor is designed to precisely control the flow of fluids or gases through a needle valve. The motor adjusts the valve opening in small, incremental movements, allowing for fine control of flow rates. It is commonly used in applications where precision is critical, such as in HVAC systems and medical equipment.

The 12V 100 RPM geared motor provides a low-speed, high-torque output, ideal for precise valve control. The gear reduction helps achieve the required torque while maintaining smooth and controlled movement, which is essential for applications like fluid flow regulation.

Yes, this motor can be customized according to your requirements. Custom options include:

- Voltage (12V)

- Gear ratio for different speeds and torque

- Shaft configuration (custom lengths or types)

- Torque output for specific needs

The 12V 100 RPM DC Geared Motor is ideal for:

- Needle valve control: Used in fluid regulation systems, including HVAC, medical equipment, and industrial processes.

- Flow control systems: Suitable for controlling gases or liquids in custom machinery or systems.

- HVAC applications: For regulating airflow and temperature control systems.

The motor’s lifespan will depend on factors such as usage, load, and environmental conditions. Under normal operation, the motor can last for many years. Proper maintenance and correct usage will extend its life.

To request a quote, simply click the "Request a Quote" button on this page or visit our Technical Support page for detailed instructions. Our team will assist you with the selection and customization process.

Yes, the 12V 100 RPM DC Geared Motor is designed for continuous operation, particularly in fluid control and regulation systems that require ongoing, stable performance.

Yes, we offer a range of speed options for this motor, including higher and lower RPM models, to suit different application needs. Please contact us for more details on speed and torque customization.

The motor is designed for standard indoor environments. For use in harsh or outdoor conditions, such as high moisture or extreme temperatures, we recommend discussing the specific requirements with us to ensure the motor is appropriately sealed or protected.

The lead time for standard orders is typically 2-4 weeks, while custom orders may take 4-6 weeks, depending on your specific requirements.