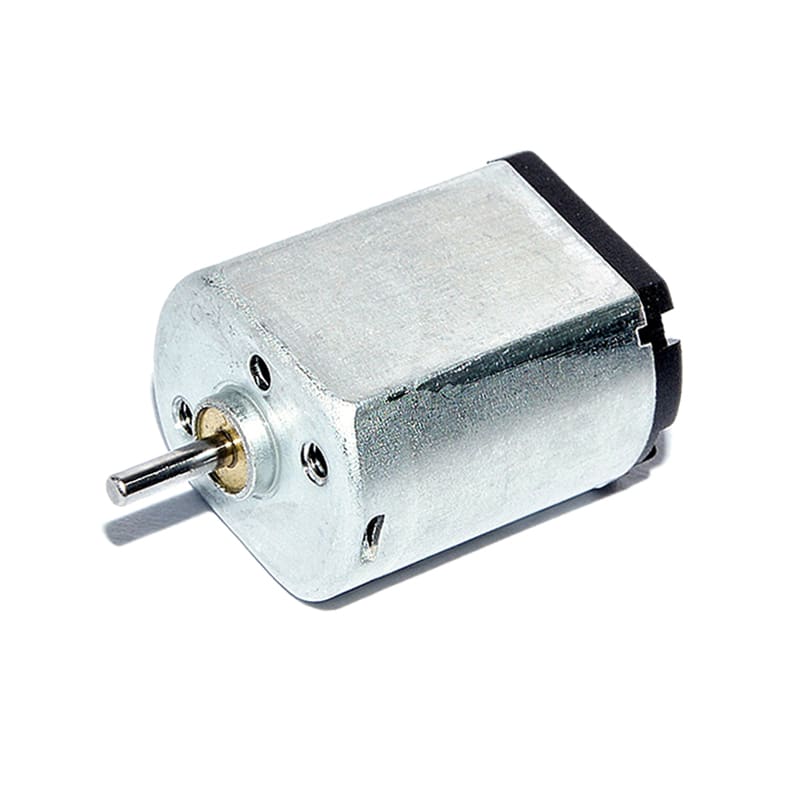

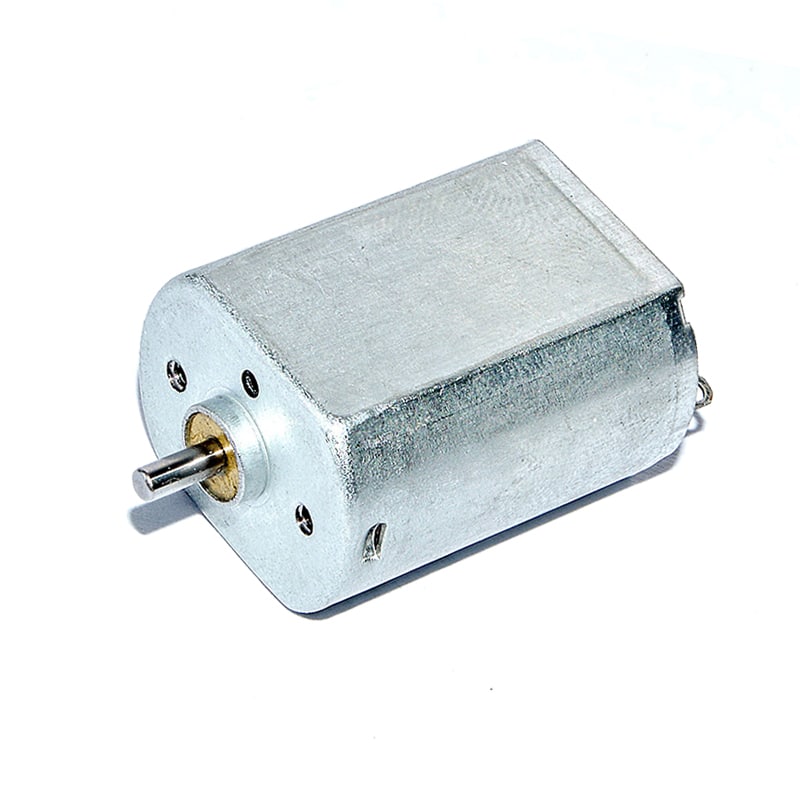

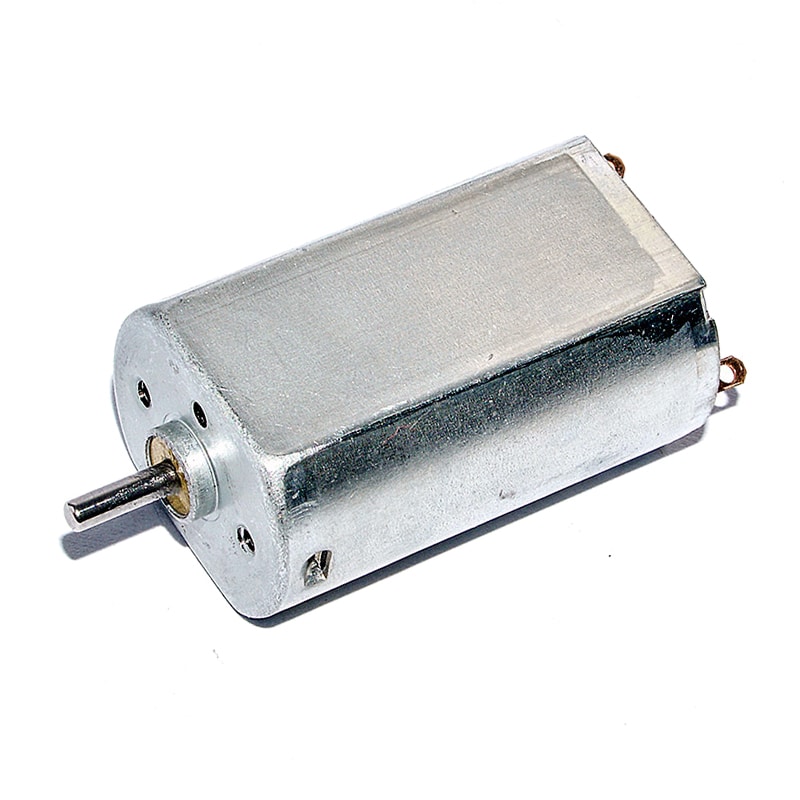

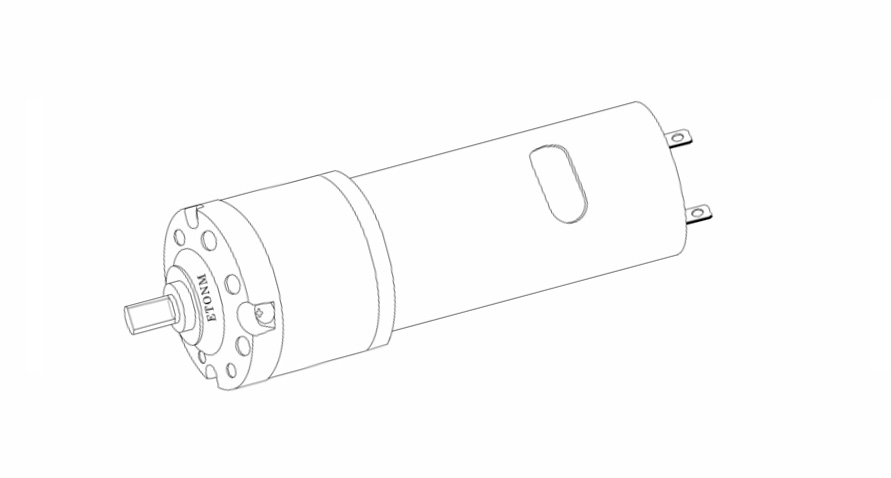

Custom Micro DC Motors for Precise, High-Performance Applications

Tailored Solutions for Robotics, Medical Devices, Consumer Electronics, and More

Our high-quality custom micro DC motors are engineered to meet your unique performance and size requirements. Perfect for applications in robotics, medical devices, and other compact, precision-driven technologies. Request your tailored motor solution today!

Micro DC Motors for Precise, High-Performance Applications

Our custom micro DC motors are specifically designed to provide high performance and precision for a variety of applications. Whether you need motors for robotics, medical devices, or other compact machinery, our tailored motor solutions are engineered to meet your exact size, voltage, and performance requirements.

- High Efficiency: Our micro DC motors offer exceptional energy efficiency, ensuring long-lasting performance even in demanding environments.

- Compact Size: These motors are built for applications that require a small form factor without compromising on power or reliability.

- Customization: Every micro DC motor is custom-designed to meet your specific needs, whether it’s adjusting torque, speed, or voltage to suit your project’s requirements.

- Versatile Applications: From precision robotics to medical equipment and consumer electronics, our micro DC motors are versatile enough for a wide range of industries.

Our Micro DC Motor Models

Our Customization Process

Seamless, Tailored Solutions from Start to Finish

At ETONM Motor, we believe that a smooth, transparent customization process is key to delivering the perfect motor solution for our clients. Our motor customization process ensures that every step of the way, from initial consultation to final delivery, is handled with precision and care.

Step 1: Initial Consultation & Requirements Gathering

We begin by understanding your specific needs. Whether you need a custom micro DC motor for a robotics project, medical device, or any other application, we collaborate closely with you to gather all the necessary details, such as:

- Motor size and shape

- Voltage and power requirements

- Torque and speed specifications

- Environmental conditions (e.g., temperature, humidity, etc.)

- Application-specific considerations (e.g., noise reduction, durability)

This step ensures we capture the full scope of your project and provide the most accurate solution.

Step 2: Design and Prototype Development

Once we have a clear understanding of your requirements, our engineering team begins designing your custom micro DC motor. This step includes:

- Detailed design based on your exact specifications

- Prototype development: We create a prototype to test the motor’s performance and functionality

- Adjustments & Refinements: Any necessary adjustments are made based on your feedback and testing results to ensure the motor meets your standards.

Step 3: Testing and Quality Control

Before moving to production, we rigorously test the prototype to ensure it meets all the required performance metrics:

- Torque and speed tests

- Environmental tests (temperature, vibration, etc.)

- Longevity and durability tests

- Noise level tests, if applicable

We ensure that the custom DC motors meet the highest industry standards for performance and reliability.

Step 4: Final Production and Delivery

Once the prototype is approved, we move to full-scale production. During this phase:

- Manufacturing: We use advanced machinery and techniques to produce your custom micro DC motors in the exact specifications.

- Final Quality Control: Every motor undergoes thorough testing before delivery to ensure it functions as designed.

- Packaging and Shipping: We take special care in packaging your motors to ensure they arrive safely and on time.

Step 5: Post-Delivery Support

Our commitment doesn’t end with delivery. After you receive your custom DC motors, we continue to offer support, including:

- Installation guidance: Assistance with integrating the motors into your application.

- Performance tracking: We help you track the motor’s performance to ensure it continues to meet your needs.

- Continuous Improvements: If you need any further adjustments or have additional requirements, we are here to provide ongoing solutions.

Technical Specifications & Capabilities

At ETONM Motor, we take pride in our ability to design and manufacture custom micro DC motors that meet the highest industry standards for performance and reliability. Our extensive technical capabilities allow us to provide solutions tailored to your exact requirements, ensuring optimal efficiency and performance for your specific application.

Below, we outline the key technical specifications and customization options available for our micro DC motors:

Voltage Range (1V - 24V)

We offer a wide range of voltages to suit various applications, from low-power electronics to high-performance systems. Custom voltage specifications are available to ensure your custom DC motor meets the precise needs of your project.

Low Noise and Vibration

Noise Reduction: Our motors are engineered to operate quietly, with low vibration, making them suitable for noise-sensitive applications such as medical devices and consumer electronics.

Compact and High Efficiency

- Size Options: Our micro DC motors come in a variety of diameters (typically from φ6mm to φ24mm), making them ideal for compact applications where space is a concern.

- Efficiency: Our motors are designed to minimize energy consumption while maintaining high power output, ensuring long-lasting performance and optimal efficiency.

Speed & Torque Control

- Speed Range: Our motors can be customized to operate at specific speeds, from low-speed precision movements to high-speed rotations.

- Torque Options: Depending on your requirements, we can design motors with a wide range of torque, ensuring the right power for your application.

Durability & Longevity

- High-Quality Materials: We use premium materials for the production of our custom micro DC motors, ensuring long-term durability and high resistance to wear and tear.

- Temperature Resistance: Our motors can be designed to withstand varying environmental conditions, from extreme cold to high temperatures.

Environmental Considerations

- Waterproof & Dustproof Options: For motors used in outdoor or industrial environments, we offer IP-rated options to ensure protection against water and dust ingress.

- Corrosion Resistance: For use in harsh environments, we provide motors with coatings or materials that are resistant to corrosion, ensuring long-lasting performance.

Customization Options:

Custom Shaft Design

We can provide motors with custom shaft designs to fit your specific application. Whether you need a specific length, material, or shape, we can accommodate your requirements.Gearbox Integration

Our custom micro DC motors can be paired with various gearboxes, including planetary gearboxes, spur gearboxes, and worm gearboxes, to provide the desired torque and speed for your application.Motor Enclosures

We offer various motor housing options to suit your needs, including lightweight, durable materials for both indoor and outdoor use. Our motor enclosures can be customized to protect the internal components from environmental factors.Customization for Special Applications

- Medical Devices: Motors that meet strict standards for medical applications, including biocompatibility and hygiene considerations.

- Robotics: Motors optimized for precise movement and high reliability, ensuring smooth operation in robotic systems.

- Consumer Electronics: Motors designed for low power consumption and quiet operation in small, portable devices.

FAQs

Custom micro DC motors are small-sized direct current motors that are specially designed and manufactured to meet specific requirements for various applications. Unlike standard motors, they are customized based on factors such as voltage, torque, speed, and size to ensure they meet the exact needs of your project. These motors are widely used in industries such as robotics, medical devices, consumer electronics, and automotive systems.

Choosing custom micro DC motors offers several key advantages:

- Tailored Specifications: Custom motors are designed to meet your specific voltage, speed, torque, and size requirements, ensuring optimal performance.

- Space Efficiency: Custom motors are ideal for compact systems where standard motors may not fit or perform optimally.

- Enhanced Performance: Customization allows for more precise control over motor performance, including low noise, high efficiency, and durability.

By selecting tailored motor solutions, you get a motor designed for your exact application, providing higher efficiency and reliability.

Custom micro DC motors are used in a variety of applications, including:

- Robotics: For precise movement and high reliability.

- Medical Devices: For applications requiring compact, quiet, and durable motors.

- Consumer Electronics: In devices like drones, portable gadgets, and electric toys.

- Automotive Systems: For powering small motors in electric vehicles or automotive components.

No matter your application, we can create custom micro DC motors that meet your specific needs.

Yes! One of the main advantages of custom micro DC motors is that we can tailor the size and shape of the motor to fit your application. Whether you need a specific diameter, length, or housing design, we can provide a solution that fits perfectly within your space constraints while meeting performance requirements.

Our custom micro DC motors are available with a voltage range from 1V to 30V, allowing us to provide solutions for both low-power and high-performance systems. If your application requires a specific voltage, we can design a motor that meets those requirements precisely.

The time required to develop a custom micro DC motor depends on the complexity of your requirements. Typically, the process from initial consultation to prototype development takes about 4 to 6 weeks. Once the prototype is approved, mass production and delivery can take an additional 2 to 4 weeks, depending on the order size and specifications.

We will provide you with an estimated timeline based on your specific needs.

Yes, there is typically a minimum order quantity (MOQ) for custom micro DC motors. The exact MOQ depends on the complexity of the motor design and your specific requirements. However, we offer flexible options and are happy to discuss your project needs to find a solution that works for both parties.

We use a variety of high-quality materials to manufacture custom micro DC motors, including:

- High-grade steel for the motor casing and shafts.

- Premium copper for windings to ensure optimal conductivity and efficiency.

- Durable plastics and alloys for motor housings and components, providing both strength and lightweight performance.

- Special coatings and materials for motors designed for harsh environments, such as corrosion-resistant coatings or waterproof seals.

We work with you to select the best materials based on your specific requirements and environmental conditions.

At ETONM Motor, quality is a top priority. Our custom micro DC motors undergo rigorous testing and quality control processes, including:

- Performance testing: Ensuring that speed, torque, and voltage requirements are met.

- Environmental testing: Simulating extreme conditions to ensure reliability in various operating environments.

- Durability testing: Ensuring long-lasting performance under normal and extreme conditions.

- Noise and vibration testing: Minimizing noise levels and ensuring smooth operation.

We maintain strict quality assurance throughout the design, prototyping, and production phases to guarantee that every motor performs optimally.

Yes, we offer post-delivery support to ensure that our custom micro DC motors continue to perform as expected. Our support includes:

- Installation guidance: Helping you integrate the motor into your application.

- Troubleshooting: Assisting with any performance issues that arise.

- Ongoing improvements: Providing modifications or upgrades if your requirements change over time.

Our commitment to customer satisfaction extends well beyond the delivery of the motor.