Discover everything you need to know about Brushless DC Motors (BLDC Motors) in this comprehensive guide. Learn about the different types, their applications, and the key benefits of using BLDC Motors in various industries.

Table of Contents

Introduction

In the world of modern engineering and automation, Brushless DC Motors (BLDC Motors) have emerged as a game-changing technology. Known for their high efficiency, durability, and versatility, BLDC Motors is powering everything from robotics and electric vehicles to medical devices and home appliances. But what exactly makes these motors so special, and why are they becoming the preferred choice across industries?

Unlike traditional brushed motors, BLDC Motors operates without brushes, relying on electronic commutation to deliver smoother, more reliable performance. This design not only reduces wear and tear but also significantly extends the motor’s lifespan, making it a cost-effective solution for both industrial and consumer applications. Whether you’re designing a high-speed drone, a precision medical tool, or an energy-efficient home appliance, understanding the types, applications, and benefits of BLDC Motors is essential.

In this comprehensive guide, we’ll explore everything you need to know about Brushless DC Motors. From their working principles and different types to their wide-ranging applications and undeniable advantages, this article will equip you with the knowledge to make informed decisions for your projects. Let’s dive into the world of BLDC Motors and discover why they are shaping the future of precision engineering.

What is a Brushless DC Motor?

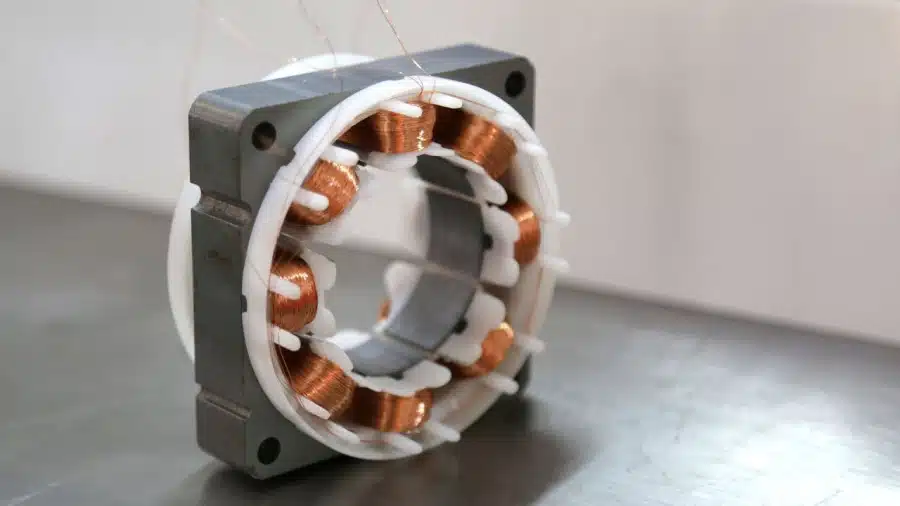

At its core, a Brushless DC Motor (BLDC Motor) is an advanced electric motor that operates without the brushes found in traditional DC motors. Instead of using brushes for commutation, BLDC Motors relies on electronic controllers to manage the flow of current to the motor windings. This innovative design eliminates the physical contact between brushes and commutators, resulting in a motor that is more efficient, longer-lasting, and less prone to wear and tear.

How Does a BLDC Motor Work?

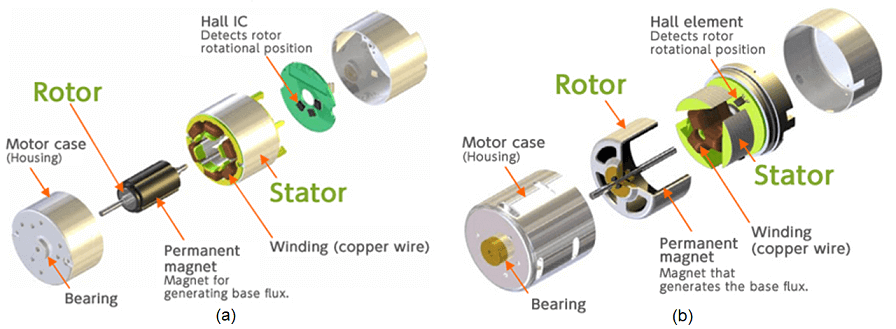

The operation of a BLDC Motor is based on the interaction between the motor’s permanent magnets and the electromagnetic fields generated by its windings. Here’s a simplified breakdown of how it works:

Permanent Magnets: The rotor of a BLDC Motor is equipped with permanent magnets, which create a stable magnetic field.

Electromagnetic Windings: The stator contains windings that generate electromagnetic fields when energized.

Electronic Commutation: An external controller (often called an ESC or Electronic Speed Controller) precisely switches the current to the windings, creating a rotating magnetic field that drives the rotor.

This process eliminates the need for brushes, which are a common point of failure in traditional brushed motors. As a result, BLDC Motors offers smoother operation, higher efficiency, and reduced maintenance.

BLDC Motors vs. Brushed Motors

One of the most common questions is: What makes BLDC Motors better than brushed motors? Here’s a quick comparison:

- Efficiency: BLDC Motors are significantly more efficient because there’s no energy loss due to brush friction.

- Lifespan: Without brushes to wear out, BLDC Motors last much longer than brushed motors.

- Maintenance: BLDC Motors require minimal maintenance, while brushed motors need regular brush replacements.

- Noise and Vibration: BLDC Motors operate more quietly and with less vibration, making them ideal for applications like medical devices and home appliances.

Why Choose a BLDC Motor?

Whether you’re designing a robotic arm, an electric vehicle, or a precision medical tool, BLDC Motors offers unparalleled performance and reliability. Their ability to deliver high torque at low speeds, combined with their compact size and energy efficiency, makes them the go-to choice for engineers and designers across industries.

In the next section, we’ll explore the different types of BLDC Motors and how they cater to specific applications.

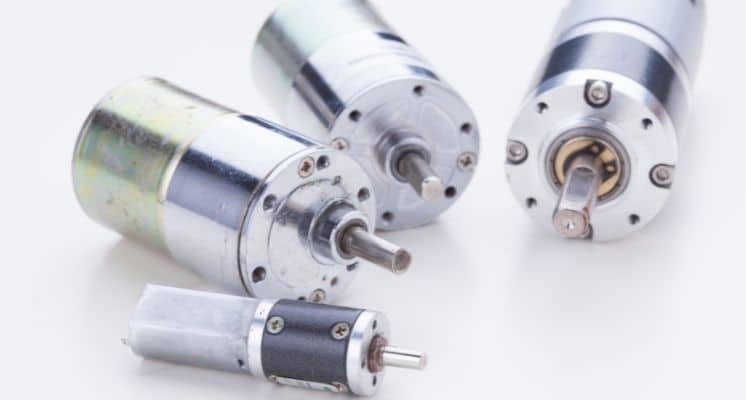

Types of BLDC Motors

Brushless DC Motors (BLDC Motors) come in various designs, each tailored to meet specific performance requirements and application needs. Understanding the different Types of BLDC Motors is crucial for selecting the right motor for your project. Here, we’ll explore the three main types of BLDC Motors and their unique characteristics.

1. Inner Rotor BLDC Motors

In Inner Rotor BLDC Motors, the rotor is located inside the stator. This design is characterized by:

High Speed: The compact rotor design allows for faster rotation, making these motors ideal for applications requiring high RPMs.

Low Inertia: The lightweight rotor reduces inertia, enabling quick acceleration and deceleration.

Common Applications: Inner Rotor BLDC Motors are widely used in drones, power tools, and HVAC systems where speed and responsiveness are critical.

2. Outer Rotor BLDC Motors

Outer Rotor BLDC Motors features a rotor that surrounds the stator. This configuration offers:

Higher Torque: The larger rotor diameter provides greater torque, making these motors suitable for applications requiring strong rotational force.

Compact Design: Despite their high torque, Outer Rotor BLDC Motors are often more compact than other motor types.

Common Applications: These motors are commonly found in ceiling fans, pumps, and robotics where torque and space efficiency are essential.

3. Disc Rotor BLDC Motors

Disc Rotor BLDC Motors have a flat, disc-shaped rotor that is mounted perpendicular to the stator. This design is known for:

Ultra-Compact Size: The flat design makes these motors ideal for applications with strict space constraints.

Low Noise: Disc Rotor BLDC Motors operate quietly, making them suitable for noise-sensitive environments.

Common Applications: These motors are often used in medical devices, optical drives, and small appliances where space and noise are critical factors.

Choosing the Right Type of BLDC Motor

Selecting the right type of BLDC Motor depends on your specific application requirements. Here are some key considerations:

Speed vs. Torque: If your application requires high speed, an Inner Rotor BLDC Motor may be the best choice. For high torque, consider an Outer Rotor BLDC Motor.

Space Constraints: For applications with limited space, a Disc Rotor BLDC Motor offers a compact solution.

Environmental Factors: Consider factors like noise, vibration, and operating conditions when choosing a motor type.

By understanding the different types of BLDC Motors, you can make an informed decision that ensures optimal performance for your project. In the next section, we’ll explore the diverse Applications of BLDC Motors across industries.

Applications of BLDC Motors

Brushless DC Motors (BLDC Motors) have become indispensable in a wide range of industries due to their efficiency, reliability, and versatility. From robotics to medical devices, these motors are powering innovations that are transforming the way we live and work. In this section, we’ll explore the diverse Applications of BLDC Motors and how they are driving progress across various fields.

1. Robotics

In the world of robotics, precision and reliability are paramount. BLDC Motors are widely used in robotic systems because of their:

High Torque: Enables robots to handle heavy loads and perform complex tasks.

Precise Control: Allows for accurate movement and positioning, essential for applications like robotic arms and drones.

Compact Size: Fits seamlessly into the compact designs of modern robots.

Examples: Industrial robots, robotic vacuum cleaners, and drones.

2. Automotive

The automotive industry is increasingly adopting BLDC Motors for their energy efficiency and durability. These motors are used in:

Electric Vehicles (EVs): BLDC Motors power the drivetrains of EVs, offering high efficiency and long-range performance.

Auxiliary Systems: They are also used in systems like power windows, windshield wipers, and HVAC fans.

Examples: Tesla’s electric vehicles, hybrid cars, and electric scooters.

3. Medical Devices

In medical devices, BLDC Motors is valued for its quiet operation and precision. They are used in:

Surgical Tools: BLDC Motors power tools like bone saws and dental drills, providing precise control and reliability.

Diagnostic Equipment: They are used in imaging systems like MRI machines and CT scanners.

Examples: Surgical robots, infusion pumps, and medical imaging devices.

4. Industrial Automation

Industrial automation relies on BLDC Motors for its high performance and low maintenance. These motors are used in:

Conveyor Systems: BLDC Motors power conveyor belts, ensuring smooth and efficient material handling.

CNC Machines: They provide precise control in machining operations.

Examples: Automated assembly lines, packaging machines, and CNC routers.

5. Home Appliances

BLDC Motors is revolutionizing home appliances by offering energy efficiency and quiet operation. They are used in:

Washing Machines: BLDC Motors provides efficient and quiet washing cycles.

Air Conditioners: They power fans and compressors, reducing energy consumption.

Examples: Smart refrigerators, vacuum cleaners, and ceiling fans.

6. Aerospace

In the aerospace industry, BLDC Motors are used for their lightweight design and high reliability. They are used in:

Drones: BLDC Motors power the propellers of drones, enabling stable and efficient flight.

Satellite Systems: They are used in satellite positioning and control systems.

Examples: Commercial drones, military UAVs, and satellite actuators.

Why BLDC Motors are Ideal for These Applications

The Applications of BLDC Motors are vast and varied, thanks to their unique advantages:

High Efficiency: Reduces energy consumption, making them ideal for battery-powered devices.

Long Lifespan: Minimizes downtime and maintenance costs.

Compact Design: Fits into space-constrained applications.

Low Noise: Ensures quiet operation in noise-sensitive environments.

By understanding the diverse Applications of BLDC Motors, you can see why they are the preferred choice for so many industries. In the next section, we’ll delve into the Benefits of Using BLDC Motors and how they can enhance your projects.

Benefits of Using BLDC Motors

Brushless DC Motors (BLDC Motors) have become a cornerstone of modern engineering, offering a host of advantages that make them superior to traditional brushed motors. Whether you’re designing a robotic system, an electric vehicle, or a medical device, understanding the Benefits of Using BLDC Motors can help you make informed decisions that enhance performance and efficiency. Here are the key advantages of BLDC Motors:

1. High Efficiency

One of the most significant benefits of BLDC Motors is their high efficiency. Unlike brushed motors, which lose energy due to friction between the brushes and commutator, BLDC Motors uses electronic commutation, eliminating this energy loss. This results in:

Lower Energy Consumption: BLDC Motors converts more electrical energy into mechanical energy, reducing power usage.

Longer Battery Life: For battery-powered devices, this efficiency translates to extended operating times.

2. Long Lifespan

BLDC Motors are designed to last. The absence of brushes means there’s no physical wear and tear from friction, leading to:

Reduced Maintenance: With no brushes to replace, BLDC Motors requires minimal maintenance.

Durability: These motors can operate reliably for thousands of hours, even in demanding environments.

3. Compact Size and Lightweight Design

The compact design of BLDC Motors makes them ideal for applications where space and weight are critical. Their lightweight construction offers:

Space Efficiency: BLDC Motors can be integrated into tight spaces, making them perfect for medical devices and drones.

Portability: Lightweight motors are easier to transport and install, reducing overall system weight.

4. Low Noise and Vibration

BLDC Motors operate quietly and smoothly, making them suitable for noise-sensitive environments. This is particularly important in applications like:

Medical Devices: Quiet operation ensures patient comfort during procedures.

Home Appliances: Low noise levels enhance the user experience in devices like washing machines and air conditioners.

5. High Torque at Low Speeds

BLDC Motors excels in applications requiring high torque at low speeds. This makes them ideal for:

Industrial Automation: Conveyor belts and CNC machines benefit from precise control and strong rotational force.

Electric Vehicles: BLDC Motors provides the torque needed for smooth acceleration and climbing steep inclines.

6. Precise Control

The electronic commutation in BLDC Motors allows for precise control over speed and position. This is crucial for applications like:

Robotics: Accurate movement and positioning are essential for robotic arms and drones.

Medical Devices: Precision is critical in surgical tools and diagnostic equipment.

7. Environmental Benefits

BLDC Motors are more environmentally friendly than traditional motors due to their:

Energy Efficiency: Reduced power consumption lowers carbon emissions.

Long Lifespan: Fewer replacements mean less waste.

Why BLDC Motors are the Future

The Benefits of Using BLDC Motors make them a superior choice for a wide range of applications. Their high efficiency, long lifespan, compact design, and precise control are driving their adoption across industries. As technology continues to advance, BLDC Motors will play an increasingly important role in shaping the future of engineering and automation.

In the next section, we’ll wrap up this guide by summarizing the key points and encouraging readers to explore how BLDC Motors can enhance their projects.

Conclusion

Throughout this guide, we’ve explored the world of Brushless DC Motors (BLDC Motors), uncovering their types, applications, and benefits. From their high efficiency and long lifespan to their compact design and precise control, BLDC Motors has proven to be a game-changing technology in modern engineering and automation.

Whether you’re designing a robotic system, an electric vehicle, or a medical device, understanding the unique advantages of BLDC Motors can help you make informed decisions that enhance performance and efficiency. Their ability to deliver high torque at low speeds, combined with their low noise and minimal maintenance, makes them the preferred choice for a wide range of industries.

As technology continues to evolve, BLDC Motors will play an increasingly important role in shaping the future of precision engineering. Their energy efficiency, durability, and versatility make them ideal for applications that demand reliability and performance.

Take the Next Step

If you’re ready to harness the power of Brushless DC Motors for your projects, explore our range of BLDC Motors today. Whether you need a high-speed motor for drones or a high-torque motor for industrial automation, we have the perfect solution for your needs. For more information, visit our FAQ page or contact our team for personalized assistance.

Related Reading

- What is a Planetary Gear Motor?

- What is a Worm Gear Motor? The Ultimate Guide to Its Applications and Benefits

- Advantages of Planetary Gear Motors

- 12V DC Motor High Torque Low RPM Performance

- Why Choose 24v Small DC Motors?

- How to Choose the Right BLDC Motor for Robotics Applications

- BLDC Motor Vs Brushed Motor: Key Differences & Best Applications

- Top 5 Applications Of BLDC Motors In Industrial Automation

- Brushless DC Motors In Medical Devices | BLDC Motor Applications

- BLDC Motors In Electric Vehicles: Types, Benefits & Applications

- BLDC Worm Gear Motor Troubleshooting: Tips & Solutions For 2025