Table of Contents

Introduction

In the world of precision motion control, planetary gear motors have emerged as a cornerstone technology, powering a wide range of applications from industrial automation to smart home devices. But what exactly is a planetary gear motor, and why is it so widely used across industries?

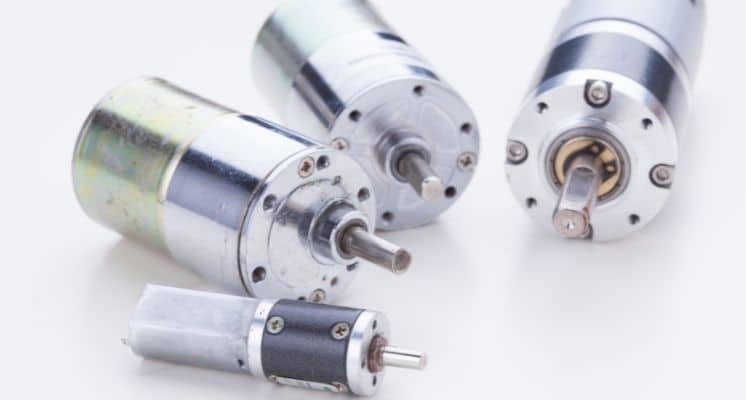

A planetary gear motor is a compact and highly efficient system that combines an electric motor with a planetary gearbox, designed to deliver exceptional torque, precision, and reliability in a small footprint. Its unique structure and working principle make it an ideal choice for applications requiring high performance in limited spaces.

Whether you’re designing a robotic arm, automating a production line, or developing a smart home device, understanding how planetary gear motors work and their advantages can help you make informed decisions for your projects. In this article, we’ll dive deep into the structure, working principle, and key benefits of planetary gear motors, and explore why they are a top choice for engineers and manufacturers worldwide.

By the end of this guide, you’ll have a clear understanding of why planetary gear motors are so effective and how they can be tailored to meet your specific needs. Let’s get started!

What is a Planetary Gear Motor?

A planetary gear motor is an integrated system that combines an electric motor with a planetary gearbox, designed to deliver high torque, precision, and efficiency in a compact form factor. Its name comes from its unique gear arrangement, which resembles the way planets orbit around the sun—a central sun gear is surrounded by multiple planet gears, all enclosed within an outer ring gear. This ingenious design allows planetary gear motors to achieve exceptional performance in a wide range of applications.

At its core, a planetary gear motor consists of two main components:

The Electric Motor: Provides the initial rotational force.

The Planetary Gearbox: Transforms the motor’s high-speed, low-torque output into low-speed, high-torque motion, making it ideal for tasks that require power and precision.

What sets planetary gear motors apart is their ability to distribute load evenly across multiple gears, reducing wear and tear while enhancing durability. This, combined with their compact size and high efficiency, makes them a preferred choice for industries ranging from robotics and automation to medical devices and smart home systems.

Whether you need to power a robotic arm, automate a conveyor belt, or drive a precision medical instrument, planetary gear motors offer a reliable and efficient solution. In the next section, we’ll break down the structure of a planetary gear motor to help you understand how its components work together to deliver such impressive performance.

Structure of a Planetary Gear Motor

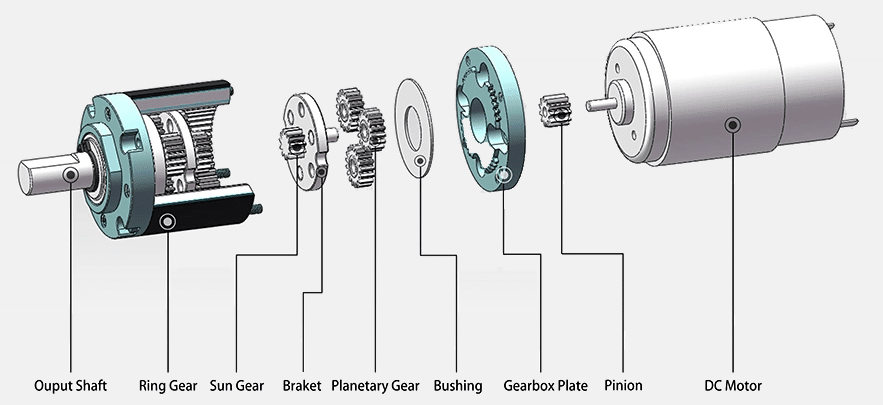

The planetary gear motor is a marvel of engineering, designed to deliver high performance in a compact and efficient package. To understand how it works, let’s take a closer look at its key components and their roles in the system.

1. Sun Gear

The sun gear is the central gear in the planetary gear system. It is directly driven by the electric motor and rotates at high speed. As the sun gear turns, it transfers its motion to the surrounding planet gears.

2. Planet Gears

Surrounding the sun gear are multiple planet gears, which are mounted on a planet carrier. These gears mesh with both the sun gear and the outer ring gear, allowing them to rotate around the sun gear while also spinning on their own axes. This dual motion is what enables the planetary gear motor to achieve high torque output.

3. Ring Gear

The ring gear is the outermost component of the system, featuring internal teeth that mesh with the planet gears. Unlike the sun gear, the ring gear is typically stationary in most configurations, providing a fixed point for the planet gears to rotate around.

4. Planet Carrier

The planet carrier holds the planet gears in place and connects them to the output shaft. As the planet gears rotate, the carrier translates their motion into a single, unified output, delivering the desired torque and speed to the application.

5. Housing

All these components are enclosed within a sturdy housing, which protects the gears from external contaminants and ensures smooth operation. The housing also helps dissipate heat, extending the motor’s lifespan.

This unique arrangement of components allows the planetary gear motor to distribute the load evenly across multiple gears, reducing stress on individual parts and enhancing overall durability. The result is a system that is not only compact but also capable of handling high torque and precision tasks with ease.

In the next section, we’ll explore how these components work together to deliver the impressive performance that planetary gear motors are known for.

How Does a Planetary Gear Motor Work?

Understanding the working principle of a planetary gear motor is key to appreciating its efficiency and versatility. Let’s break down the process step by step to see how this compact system transforms input power into high-torque, precision output.

Step 1: Motor Input

The process begins with the electric motor, which generates rotational force. This force is transferred directly to the sun gear, causing it to rotate at high speed.

Step 2: Sun Gear Drives Planet Gears

As the sun gear rotates, it engages the surrounding planet gears. These gears are mounted on a planet carrier and mesh with both the sun gear and the stationary ring gear. The interaction between these components causes the planet gears to perform two simultaneous motions:

Rotation: The planet gears spin on their own axes.

Revolution: The planet gears orbit around the sun gear.

Step 3: Torque Multiplication

The dual motion of the planet gears creates a mechanical advantage, significantly increasing the system’s torque output. This is one of the key reasons why planetary gear motors are so effective in applications requiring high power in a compact design.

Step 4: Output Through the Planet Carrier

The planet carrier, which holds the planet gears, translates their combined motion into a single, unified output. This output is then transferred to the application via the output shaft, delivering the precise speed and torque needed for the task at hand.

Step 5: Smooth and Efficient Operation

The even distribution of load across multiple gears ensures smooth operation and minimizes wear and tear. Additionally, the compact design of the planetary gear motor reduces energy loss, making it highly efficient.

Why This Matters

The working principle of a planetary gear motor makes it ideal for applications that demand high torque, precision control, and compact size. From robotics and industrial automation to medical devices and smart home systems, this technology powers some of the most advanced machinery in the world.

In the next section, we’ll explore the key advantages of planetary gear motors and why they are a top choice for engineers and manufacturers.

Advantages of Planetary Gear Motors

Planetary gear motors are widely regarded as one of the most efficient and versatile solutions for motion control, and for good reason. Their unique design and working principle offer a range of technical advantages that make them ideal for demanding applications. Here are the key benefits that set planetary gear motors apart:

1. High Torque Density

One of the standout features of planetary gear motors is their ability to deliver high torque in a compact size. The load is distributed evenly across multiple planet gears, allowing the motor to generate significant power without requiring a large footprint. This makes them perfect for space-constrained applications like robotics and medical devices.

2. Exceptional Efficiency

Planetary gear motors are designed to minimize energy loss, ensuring high efficiency in power transmission. The even distribution of forces reduces friction and wear, while the compact design helps maintain optimal performance even under heavy loads.

3. Precision Control

Thanks to their low backlash and high positional accuracy, planetary gear motors excel in applications that require precise motion control. Whether it’s positioning a robotic arm or adjusting a medical instrument, these motors deliver the accuracy needed for critical tasks.

4. Compact and Lightweight

The integrated design of planetary gear motors combines the motor and gearbox into a single, compact unit. This not only saves space but also reduces the overall weight of the system, making them ideal for portable and mobile applications.

5. Durability and Long Lifespan

The robust construction of planetary gear motors ensures long-lasting performance, even in harsh environments. The load-sharing nature of the planetary gear system reduces stress on individual components, minimizing wear and extending the motor’s lifespan.

6. Low Noise and Vibration

Planetary gear motors operate with minimal noise and vibration, making them suitable for applications where quiet operation is essential. This is particularly important in industries like medical care and smart home devices.

7. Versatility

From industrial automation to consumer electronics, planetary gear motors can be customized to meet the specific needs of a wide range of applications. Their adaptability makes them a go-to solution for engineers and designers.

Why These Advantages Matter

The combination of high torque, precision, efficiency, and durability makes planetary gear motors a top choice for industries that demand reliable and high-performance motion control solutions. Whether you’re designing a high-speed robotic system or a compact medical device, these motors offer the performance and flexibility you need.

In the next section, we’ll explore the diverse applications of planetary gear motors and how they are transforming industries worldwide.

Applications of Planetary Gear Motors

Planetary gear motors are a cornerstone of modern engineering, powering a wide range of applications across industries. Their unique combination of high torque, precision, and compact design makes them indispensable in both everyday devices and advanced technologies. Here are some of the most common and innovative applications of planetary gear motors:

1. Industrial Automation

In manufacturing and production lines, planetary gear motors are used to drive robotic arms, conveyor belts, and assembly machines. Their high torque and precision ensure efficient and reliable operation, even in demanding environments.

2. Robotics

From industrial robots to service robots, planetary gear motors provide the precision control and compact size needed for complex movements. They are often used in joint actuators, grippers, and mobile robot drives.

3. Medical Devices

In the medical field, planetary gear motors are found in surgical robots, infusion pumps, and imaging equipment. Their quiet operation, precision, and reliability are critical for ensuring patient safety and effective treatment.

4. Smart Home Systems

Planetary gear motors are at the heart of many smart home devices, such as automatic curtains, smart locks, and adjustable furniture. Their compact design and low noise make them ideal for enhancing comfort and convenience in residential settings.

5. Automotive Industry

In vehicles, planetary gear motors are used in electric power steering systems, seat adjusters, and sunroof mechanisms. Their durability and efficiency contribute to improved performance and user experience.

6. Aerospace and Defense

Planetary gear motors play a vital role in aerospace applications, including satellite positioning systems, drone actuators, and military equipment. Their ability to withstand extreme conditions and deliver precise control makes them a trusted choice in this sector.

7. Consumer Electronics

From 3D printers to camera gimbals, planetary gear motors enable precise motion control in a variety of consumer electronics. Their compact size and efficiency help manufacturers create sleek and innovative products.

8. Renewable Energy

In wind turbines and solar tracking systems, planetary gear motors are used to adjust the position of blades and panels for optimal energy capture. Their high torque and durability ensure reliable performance in outdoor environments.

9. Agricultural Machinery

Planetary gear motors are used in automatic seeders, irrigation systems, and harvesting equipment. Their ability to handle heavy loads and harsh conditions makes them a valuable asset in modern agriculture.

10. Vending Machines and Point-of-Sale Systems

In commercial applications, planetary gear motors power vending machine mechanisms and POS systems, ensuring smooth and reliable operation for businesses.

Why These Applications Matter

The versatility of planetary gear motors makes them a go-to solution for engineers and designers across industries. Whether it’s improving efficiency in manufacturing, enhancing precision in medical devices, or enabling innovation in consumer electronics, these motors are driving progress in countless ways.

In the next section, we’ll discuss why Etonm Motor’s planetary gear motors stand out in the market and how they can meet your specific needs.

Why Choose Etonm Motor’s Planetary Gear Motors?

When it comes to planetary gear motors, not all products are created equal. At Etonm Motor, we pride ourselves on delivering high-quality, customized solutions that meet the unique needs of our clients. Here’s why our planetary gear motors stand out in the market:

1. Customization Options

We understand that every application has specific requirements. That’s why we offer fully customizable planetary gear motors, tailored to your exact specifications. Whether you need a specific torque rating, size, or mounting configuration, we can deliver a solution that fits your needs.

2. High-Quality Materials

Our motors are built using premium materials that ensure durability and long-lasting performance. From robust gear components to high-efficiency motors, every part is designed to withstand demanding operating conditions.

3. Advanced Manufacturing Techniques

At Etonm Motor, we leverage state-of-the-art manufacturing processes to produce planetary gear motors that meet the highest industry standards. Our precision engineering ensures consistent quality and reliability in every unit.

4. Expertise and Experience

With years of experience in the motor industry, our team of engineers and technicians brings unparalleled expertise to every project. We work closely with you to understand your requirements and provide solutions that exceed expectations.

5. Comprehensive Support

From initial consultation to after-sales service, we are committed to providing end-to-end support for our clients. Our team is always available to answer your questions, troubleshoot issues, and ensure your satisfaction.

6. Competitive Pricing

Despite our focus on quality and customization, we offer competitive pricing to ensure our products are accessible to businesses of all sizes. We believe that high performance shouldn’t come with a high price tag.

7. Wide Range of Applications

Our planetary gear motors are versatile and can be used in a variety of industries, including robotics, medical devices, industrial automation, and smart home systems. Whatever your application, we have a solution that fits.

8. Commitment to Innovation

At Etonm Motor, we are constantly exploring new technologies and design improvements to stay ahead of the curve. Our commitment to innovation ensures that our products remain at the forefront of the industry.

Why Etonm Motor?

Choosing Etonm Motor means partnering with a company that values quality, innovation, and customer satisfaction. Our planetary gear motors are designed to deliver exceptional performance, reliability, and value, making them the ideal choice for your next project.

Conclusion

Planetary gear motors are a testament to the power of innovative engineering, offering high torque, precision control, and compact design in a single, efficient package. From industrial automation and robotics to medical devices and smart home systems, these motors are transforming industries and enabling new possibilities.

Throughout this article, we’ve explored the structure, working principle, advantages, and applications of planetary gear motors, highlighting why they are a top choice for engineers and manufacturers worldwide. Whether you’re designing a high-performance robotic system or a compact consumer device, planetary gear motors provide the reliability and efficiency you need to succeed.

At Etonm Motor, we take pride in delivering customized planetary gear motor solutions that meet the unique demands of your projects. With our commitment to quality, innovation, and customer satisfaction, we are your trusted partner for all your motion control needs.

Ready to take your application to the next level? Contact Etonm Motor today to learn more about our planetary gear motors and how we can help you achieve your goals. Let’s work together to power the future of innovation!

Our Planetary Gear Motors

Explore our wide range of Planetary Gear Motor Models, designed to meet diverse application needs. Whether you require high torque DC gear motors for industrial automation or compact planetary gear motors for robotics, our fully customizable solutions ensure optimal performance. Each motor is engineered with precision and can be tailored to specific voltage, gear ratio, and size requirements, making them ideal for robotics, medical devices, and beyond.

- Size(WL):Φ16mm

- Voltage:3-12VDC

- Speed:10-2000rpm

- Torque:0.05-5kg.cm

- Typical use:Safe and Locking、Electric Curtain、Electric Valve

- Size(WL):Φ16mm

- Voltage:6-12VDC

- Speed:10-2000rpm

- Torque:0.05-5kg.cm

- Typical use:Electric curtain/Blinds

- Size(WL):Φ22mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-8kg.cm

- Typical use: Electric Curtain/Blinds、Safe and Locking、Office Automation

- Size(WL):Φ22mm

- Voltage:3-12VDC

- Speed:1-2000rpm

- Torque:0.1-6kg.cmrpm

- Typical use: Electric Curtain、Safe and Locking、Office & Home Automation

- Size(WL):Φ22mm

- Voltage:3-24VDC

- Speed:1-2000rpm

- Torque:0.1-6kg.cm

- Typical use: Office & Home Automation、Equipment and Apparatus、Actuator

- Size(WL):Φ22mm

- Voltage:6-12VDC

- Speed:1-1500rpm

- Torque:0.1-8kg.cm

- Typical use: Electric curtain/Blinds、Antenna

- Size(WL):Φ24mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-8kg.cm

- Typical use: Electric curtain/Blinds、Antenna

- Size(WL):Φ28mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cm

- Typical use: Electric curtain、Actuator and Electric Valve、Office & Home Automation

- Size(WL):Φ32mm

- Voltage:12-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cm

- Typical use: Electric curtain、Actuator and Electric Valve、Coffee Bean Grinder and Coffee Maker

- Size(WL):Φ32mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cmrpm

- Typical use: Home and Office Automation、Equipment and Apparatus、Coffee Machine

- Size(WL):Φ36mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-60kg.cm

- Typical use: Robotics、Pump and Electric Valve、Banking and Medical Equipment

- Size(WL):Φ36mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cm

- Typical use: Home and Office Automation、Equipment and Apparatus、Pump

- Size(WL):Φ42mm

- Voltage:12-24VDC

- Speed:1-1000rpm

- Torque:0.1-80kg.cm

- Typical use: Apparatus and Equipments、Actuator and Robotics、Conveyor Roller

- Size(WL):Φ56mm

- Voltage:12-24VDC

- Speed:1-200rpm

- Torque:10-200kg.cm

- Typical use: Home and Office Automation、Equipment and Apparatus、Medical Device

- Size(WL):Φ32mm

- Voltage:6-24VDC

- Speed:1-1500rpm

- Torque:0.1-40kg.cm

- Typical use: Home and Office Automation、Equipment and Apparatus、Electric Oift

- Size(WL):Φ42mm

- Voltage:12-12VDC

- Speed:1-200rpm

- Torque:10-200kg.cm

- Typical use:Home and Office Automation、Equipment and Apparatus、Medical Device