Table of Contents

Introduction

When it comes to compact, high-torque motor solutions, the Worm Gear Motor stands out as a versatile and reliable choice. This unique type of motor combines a worm screw and a gear to deliver exceptional performance in a small package, making it ideal for applications where space and efficiency are critical. From powering smart home devices to driving precision robotics, Worm Gear Motors are at the heart of countless innovations.

At Etonm Motor, we specialize in designing and manufacturing customized Worm Gear Motors, including popular models like the 12V DC Worm Gear Motor and 24V Worm Gear Motor, tailored to meet the demands of industries such as medical care, security, and electric valves. Whether you need a Worm Gear Motor 6 RPM for slow, controlled motion or a 12V HIGH TORQUE variant for heavy-duty tasks, our solutions are engineered to deliver unmatched performance.

In this guide, we’ll dive into what makes Worm Gear Motors so unique, how they work, and why they’re the go-to choice for applications requiring precision, reliability, and compact design. Let’s explore the world of Worm Gear Motors and discover how they can power your next project.

What is a Worm Gear Motor?

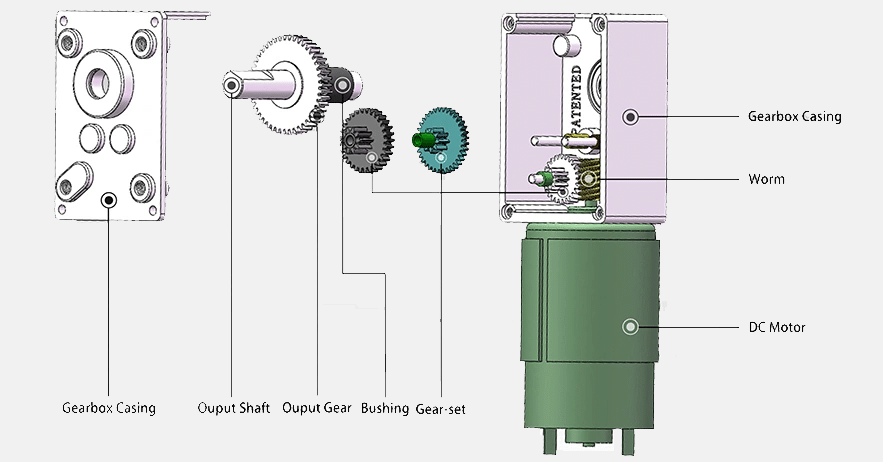

A Worm Gear Motor is a specialized type of gear motor that combines a worm screw and a gear to achieve precise motion control and high torque output in a compact design. The worm screw, which resembles a threaded shaft, meshes with the gear (often called the worm wheel) to transfer motion and power. This unique configuration allows the motor to operate smoothly at low speeds while delivering significant torque, making it an ideal solution for applications requiring both precision and strength.

One of the standout features of a Worm Gear Motor is its ability to prevent backdriving, meaning the gear cannot turn the worm screw. This self-locking mechanism ensures stability and safety in applications where holding position is critical, such as in electric valves or security systems. Additionally, the compact and efficient design of Worm Gear Motors, including variants like the Helical Worm Gear Motor, makes them perfect for use in space-constrained environments like smart home devices and medical equipment.

Whether you’re looking for a 12V DC Worm Gear Motor for lightweight applications or a 24V Worm Gear Motor for more demanding tasks, these motors offer a reliable and energy-efficient solution. Their versatility and performance have made them a popular choice across industries, from robotics to vending machines.

How Does a Worm Gear Motor Work?

The working principle of a Worm Gear Motor is both simple and ingenious. At its core, the motor consists of two main components: the worm screw and the worm wheel (gear). The worm screw, which is typically mounted on the motor’s input shaft, has a helical thread that meshes with the teeth of the worm wheel. When the motor is powered, the worm screw rotates, and its threads engage with the gear, causing the worm wheel to turn.

One of the key advantages of this design is its ability to achieve high torque output at low speeds. Because the worm screw and gear interact at a 90-degree angle, the motion is transferred efficiently, allowing the motor to handle heavy loads with minimal effort. This makes Worm Gear Motors, such as the Worm Gear Motor 6 RPM or the 12V RIGHT ANGLE GEAR MOTOR, ideal for applications requiring slow, controlled movement and significant force, like in conveyor systems or automated gates.

Another notable feature is the self-locking mechanism inherent in most Worm Gear Motors. Due to the angle of the worm screw’s threads, the gear cannot reverse the motion and turn the screw. This prevents backdriving, ensuring stability and safety in applications where holding a position is critical, such as in medical devices or security systems.

Whether it’s a 12V DC Worm Gear Motor for lightweight tasks or a 24V Worm Gear Motor for more demanding operations, the efficiency and reliability of this mechanism make it a cornerstone of modern engineering.

Types of Worm Gear Motors

Worm Gear Motors come in a variety of configurations to meet the diverse needs of different applications. Each type is designed to deliver specific performance characteristics, making it essential to choose the right motor for your project. Here are some of the most common types:

12V DC Worm Gear Motor

This type is widely used in low-power applications where energy efficiency and compact size are critical. It’s perfect for devices like smart home systems, small robotics, and sanitary dispensers. The 12V DC Worm Gear Motor is known for its reliability and ease of integration into battery-operated systems.

24V Worm Gear Motor

For applications requiring higher power and torque, the 24V Worm Gear Motor is an excellent choice. It’s commonly used in industrial equipment, electric valves, and vending machines, where it delivers robust performance and durability.

Worm Gear Motor 6 RPM

Designed for applications that require slow, precise movement, the Worm Gear Motor 6 RPM is ideal for conveyor systems, automated gates, and medical devices. Its low-speed operation ensures smooth and controlled motion.

Worm Gear Motor 12V HIGH TORQUE

When high torque is essential, the Worm Gear Motor 12V HIGH TORQUE steps in. This type is perfect for heavy-duty tasks like lifting mechanisms, security systems, and robotics, where it provides exceptional strength without compromising on efficiency.

12V RIGHT ANGLE GEAR MOTOR

The 12V RIGHT ANGLE GEAR MOTOR is designed for applications where space is limited, and motion needs to be redirected at a 90-degree angle. It’s commonly used in compact devices like cameras, printers, and small machinery.

Helical Worm Gear Motor

Known for its smooth and quiet operation, the Helical Worm Gear Motor is ideal for applications where noise reduction is important, such as in medical equipment or office automation devices. Its helical gear design also enhances efficiency and longevity.

By understanding the different types of Worm Gear Motors, you can select the one that best fits your specific requirements. At Etonm Motor, we offer a wide range of customizable options to ensure you get the perfect motor for your application.

Applications of Worm Gear Motors

Worm Gear Motors are incredibly versatile, making them indispensable in a wide range of industries and applications. Their compact size, high torque output, and precise motion control make them ideal for both everyday devices and specialized equipment. Here are some of the key areas where Worm Gear Motors shine:

Smart Home Devices

From automated blinds to smart locks, Worm Gear Motors are at the heart of many smart home innovations. Their quiet operation and reliability ensure seamless integration into home automation systems.

Sanitary Dispensers

In touchless soap dispensers, paper towel dispensers, and hand dryers, Worm Gear Motors provide the precise motion control needed for smooth and hygienic operation.

Security Systems

Worm Gear Motors are widely used in security cameras, automated gates, and access control systems. Their self-locking mechanism ensures stability and safety, making them a trusted choice for security applications.

Electric Valves and Meters

In water treatment plants, HVAC systems, and industrial automation, Worm Gear Motors are used to control valves and meters with precision and reliability. Models like the 24V Worm Gear Motor are particularly suited for these demanding environments.

Robotics

Whether it’s a small robotic arm or a mobile robot, Worm Gear Motors provide the high torque and compact design needed for efficient and precise movement. The 12V DC Worm Gear Motor is a popular choice for lightweight robotic applications.

Vending Machines

Worm Gear Motors are essential in vending machines, where they drive mechanisms for dispensing products. Their durability and efficiency ensure smooth operation even in high-use scenarios.

Medical Care

In medical devices like hospital beds, infusion pumps, and diagnostic equipment, Worm Gear Motors offer the precision and reliability required for critical healthcare applications. The Helical Worm Gear Motor is often preferred for its quiet and smooth operation.

Industrial Automation

From conveyor belts to packaging machines, Worm Gear Motors play a vital role in industrial automation. Their ability to handle heavy loads and operate at low speeds makes them ideal for these tasks.

By powering such a diverse range of applications, Worm Gear Motors have proven to be a cornerstone of modern technology. At Etonm Motor, we specialize in providing customized solutions to meet the unique needs of each industry, ensuring optimal performance and reliability.

Benefits of Using Worm Gear Motors

Worm Gear Motors are highly valued across industries for their unique combination of features and advantages. Whether you’re designing a compact smart home device or a heavy-duty industrial machine, these motors offer several benefits that make them a top choice. Here’s why Worm Gear Motors stand out:

High Torque Output

One of the most significant advantages of Worm Gear Motors is their ability to deliver high torque at low speeds. This makes them ideal for applications like conveyor systems, lifting mechanisms, and robotics, where strength and precision are essential. For example, the Worm Gear Motor 12V HIGH TORQUE is specifically designed to handle demanding tasks with ease.

Compact and Space-Saving Design

Worm Gear Motors are known for their compact size, making them perfect for applications where space is limited. Models like the 12V RIGHT ANGLE GEAR MOTOR are designed to fit into tight spaces while still delivering exceptional performance.

Self-Locking Mechanism

The unique design of Worm Gear Motors prevents backdriving, meaning the gear cannot turn the worm screw. This self-locking feature ensures stability and safety in applications like security systems, medical devices, and electric valves, where holding position is critical.

Energy Efficiency

Worm Gear Motors, such as the 12V DC Worm Gear Motor, are highly energy-efficient, making them ideal for battery-operated devices and systems where power consumption is a concern.

Smooth and Quiet Operation

With advancements like the Helical Worm Gear Motor, these motors operate smoothly and quietly, making them suitable for noise-sensitive environments like medical care facilities and office automation systems.

Durability and Longevity

Built to withstand demanding conditions, Worm Gear Motors are known for their durability and long service life. This reliability reduces maintenance costs and downtime, making them a cost-effective solution for industrial and commercial applications.

Versatility

From Worm Gear Motor 6 RPM models for slow, controlled motion to 24V Worm Gear Motors for high-power applications, these motors are incredibly versatile. They can be customized to meet the specific needs of various industries, including smart home, robotics, and medical care.

By leveraging these benefits, Worm Gear Motors provide a reliable and efficient solution for a wide range of applications. At Etonm Motor, we specialize in designing and manufacturing high-quality Worm Gear Motors tailored to your unique requirements.

Why Choose Etonm Motor for Worm Gear Motors?

When it comes to sourcing high-quality Worm Gear Motors, Etonm Motor stands out as a trusted partner for businesses across industries. With years of expertise in designing and manufacturing customized motor solutions, we are committed to delivering products that meet the highest standards of performance, reliability, and innovation. Here’s why you should choose us:

Customization Expertise

At Etonm Motor, we understand that every application has unique requirements. Whether you need a 12V DC Worm Gear Motor for a compact smart home device or a 24V Worm Gear Motor for heavy-duty industrial use, we offer fully customizable solutions tailored to your specific needs.

Wide Range of Products

Our extensive product lineup includes various types of Worm Gear Motors, such as the Worm Gear Motor 6 RPM for slow, precise motion, the Worm Gear Motor 12V HIGH TORQUE for demanding tasks, and the Helical Worm Gear Motor for smooth and quiet operation. Whatever your application, we have the right motor for you.

Commitment to Quality

Quality is at the core of everything we do. Our Worm Gear Motors are manufactured using premium materials and advanced technologies, ensuring durability, efficiency, and long service life. Rigorous testing processes guarantee that every motor meets our high standards before it reaches you.

Innovative Solutions

We stay at the forefront of motor technology, continuously innovating to provide cutting-edge solutions. Our 12V RIGHT ANGLE GEAR MOTOR, for example, is designed to optimize space and performance in compact applications, showcasing our commitment to solving real-world challenges.

Global Reach, Local Support

With a global customer base, we have the experience and resources to serve clients worldwide. Our dedicated support team is always available to assist with technical inquiries, customization requests, and after-sales service, ensuring a seamless experience from start to finish.

Competitive Pricing

We believe that high-quality Worm Gear Motors should be accessible to all. By optimizing our manufacturing processes, we offer competitive pricing without compromising on quality, making us a cost-effective choice for businesses of all sizes.

Sustainability Focus

At Etonm Motor, we are committed to sustainability. Our motors are designed to be energy-efficient, reducing power consumption and environmental impact. We also prioritize eco-friendly practices in our manufacturing processes.

Whether you’re working on a smart home project, developing medical equipment, or automating industrial processes, Etonm Motor is your trusted partner for Worm Gear Motors. Explore our product range today and discover how we can power your next innovation.

Conclusion

Worm Gear Motors are a cornerstone of modern technology, offering a unique combination of high torque, compact design, and precise motion control. From powering smart home devices and robotics to driving industrial automation and medical equipment, these versatile motors have proven their value across a wide range of applications. Whether you need a 12V DC Worm Gear Motor for lightweight tasks, a 24V Worm Gear Motor for heavy-duty operations, or a specialized Helical Worm Gear Motor for smooth and quiet performance, there’s a solution to meet your needs.

At Etonm Motor, we take pride in being a trusted provider of high-quality, customizable Worm Gear Motors. Our commitment to innovation, quality, and customer satisfaction ensures that you receive the perfect motor for your specific requirements. With products like the Worm Gear Motor 6 RPM for slow, controlled motion and the 12V RIGHT ANGLE GEAR MOTOR for space-constrained applications, we are dedicated to helping you achieve your goals.

If you’re ready to explore the possibilities of Worm Gear Motors, we invite you to contact us or visit our website to learn more about our product range. Let Etonm Motor be your partner in powering the next generation of innovations. Share this guide with your network, and don’t hesitate to reach out with any questions—we’re here to help!

Our Worm Gear Motors

ET-WGM34A

ET-WGM46

ET-WGM58A

Related Reading

- Advantages of Planetary Gear Motors

- How to Calculate Transmission Gear Ratio: A Comprehensive Guide for Gear Systems

- 12V DC Motor High Torque Low RPM Performance

- Comprehensive Guide to Low-Noise Gear Motors: Features, Types, and Applications

- Why Choose 24v Small DC Motors?

- BLDC Worm Gear Motor Troubleshooting: Tips & Solutions For 2025