Curious about DC motor torque? This guide breaks it down—what it is, how it works, and why it matters in applications like robotics and smart homes. Learn more from Etonm Motor!

Table of Contents

Introduction

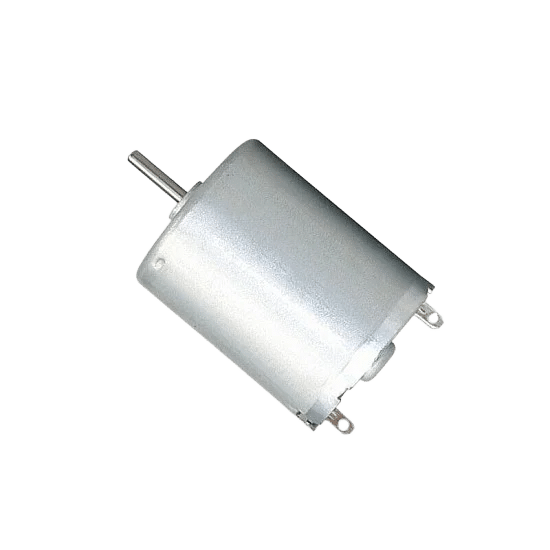

Ever wonder why your robot vacuum glides effortlessly around corners or why your smart blinds open with just the right amount of oomph? The answer lies in something called DC motor torque. It’s the unsung hero behind the spin of countless devices we use every day, from vending machines to medical gadgets. But what exactly is it, and why should you care? In this guide, we’re breaking it down—plain and simple—no engineering degree required. Drawing from years of crafting custom motors at Etonm Motor, we’ll walk you through what DC motor torque is, how it works, and why it’s a big deal in the real world. Stick around, because by the end, you’ll see how this little force makes a lot of things tick—and maybe even pick up a tip or two for your next project!

What Exactly Is DC Motor Torque?

So, let’s get to the heart of it: what is DC motor torque? In the simplest terms, torque is the twisting force that makes something spin. Picture yourself trying to open a stubborn pickle jar—that twist you apply with your wrist? That’s torque. Now, swap your hand for a DC motor, and you’ve got the same idea: it’s the muscle behind the rotation. In a DC motor, torque is what turns the shaft and gets things moving, whether it’s powering a robot arm or flipping open a smart lock.

Specifically, DC motor torque comes from the interplay of electricity and magnetism inside the motor. When current flows through the motor’s coils, it creates a magnetic field that pushes against another field (usually from permanent magnets). That push is what generates the twist—or torque—that spins the motor. The stronger the push, the more torque you get. Pretty neat, right?

At Etonm Motor, we’ve spent years fine-tuning this “twist” for all sorts of custom motors—think micro DC motors for tiny gadgets or beefy planetary gear motors for heavier lifting. It’s not just about raw power, though. Torque is about control, too—delivering just the right amount of spin for the job. So whether you’re designing a vending machine that doesn’t jam or a medical device that needs precision, understanding DC motor torque is step one. Up next, we’ll dig into how this magic actually happens inside the motor.

How Does DC Motor Torque Work?

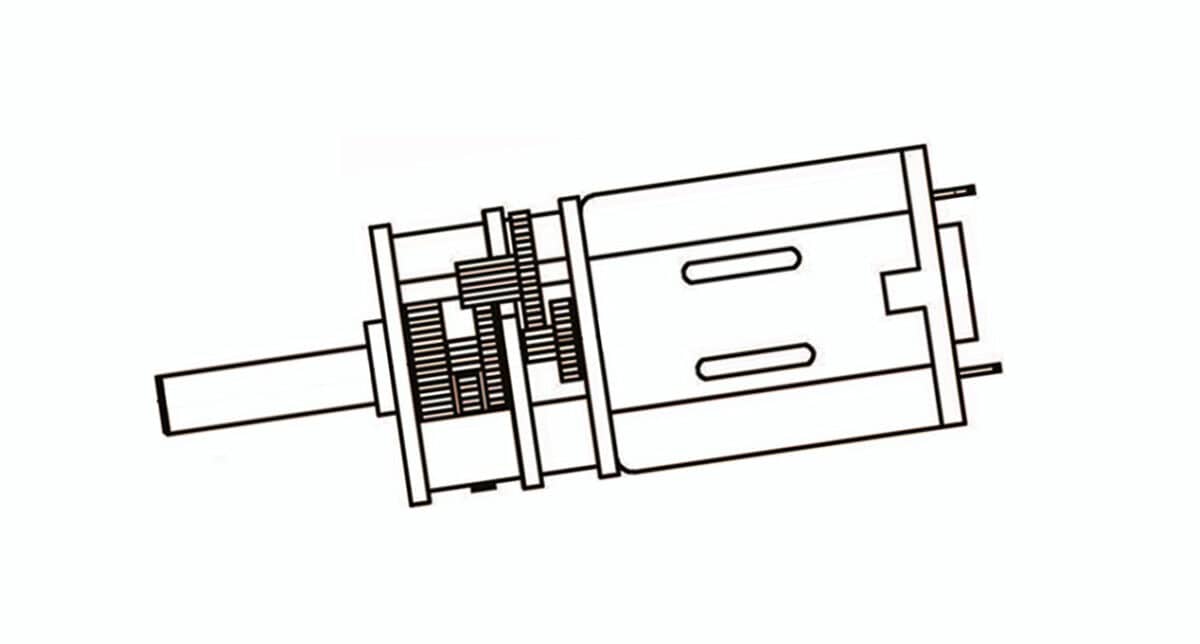

Okay, now that we know what DC motor torque is, let’s peek under the hood—how does DC motor torque work? It’s not as complicated as it might sound, and honestly, it’s kind of cool once you get the gist. At its core, a DC motor turns electricity into motion, and torque is the key player making that happen.

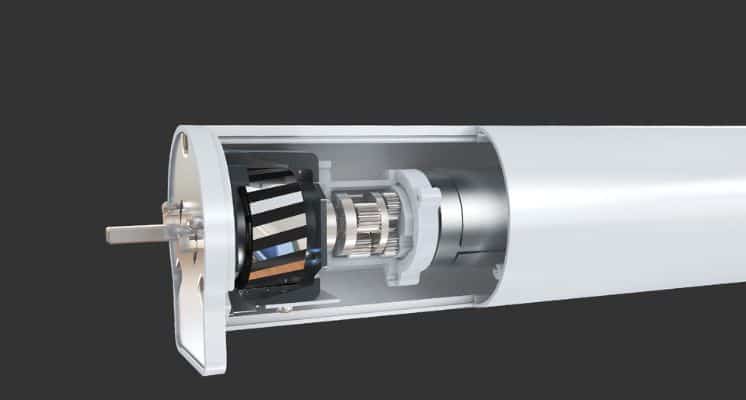

Here’s the quick version: when you feed power into a DC motor—say, from a battery—electric current flows through a coil of wire called the armature. This sits inside a magnetic field, usually from permanent magnets or another set of coils. The current in the armature creates its own magnetic field, and like a pair of magnets that don’t get along, these fields push against each other. That push spins the armature, and voilà—torque is born! The motor’s shaft spins, and whatever it’s attached to (a gear, a wheel, you name it) starts moving.

The brushes and commutator—those little parts you might’ve seen in motor diagrams—keep the current flowing in the right direction to maintain that spin. It’s like a perfectly timed dance. Want a fun fact? The torque in a DC motor can make or break something as simple as a vending machine dropping your snack—too little, and it stalls; too much, and it’s overkill. At Etonm Motor, we tweak this dance for everything from brushless motors to worm gear setups, depending on what our customers need. Next, we’ll look at what tweaks that torque up or down.

Factors Affecting DC Motor Torque

So, we’ve got the basics of how torque works—but what makes it stronger or weaker? The truth is, DC motor torque isn’t a one-size-fits-all deal. Several factors affect it, and understanding them can mean the difference between a motor that purrs and one that just sputters. Let’s break down the big players.

First up: voltage. More juice flowing into the motor usually means more torque. It’s like giving your car a bigger gas pedal push—you get more oomph. But here’s the catch—crank it too high, and you might overheat the motor or hit its design limits. Next, there’s current. Since torque comes from that magnetic push we talked about, more current through the armature amps up the force. Simple, right? Well, until resistance or heat steps in to complicate things.

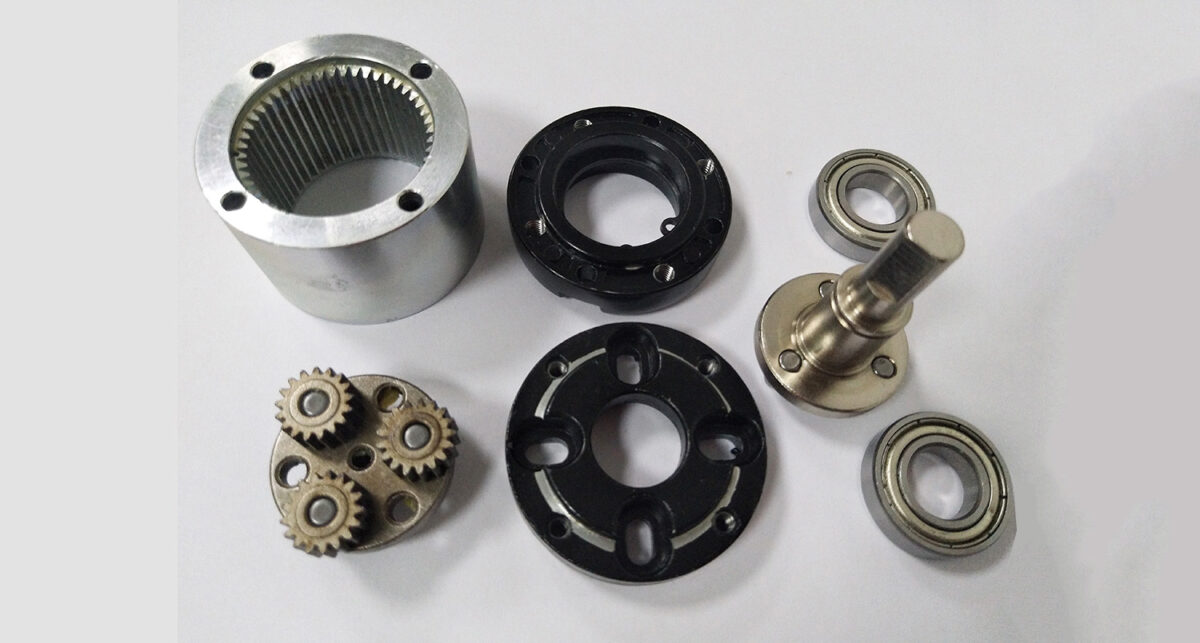

Then there’s the motor design itself. A planetary gear motor, for instance, can multiply torque compared to a basic setup—perfect for heavy-duty jobs like robotics. Meanwhile, a worm gear motor might trade some speed for extra torque control, great for precise stuff like electric valves. Even the size of the armature or the strength of the magnets plays a role. At Etonm Motor, we’ve seen this firsthand—tweaking these factors lets us build everything from tiny micro DC motors for smart home gadgets to beefy brushless ones for medical gear.

Temperature can sneak in too—hot motors lose efficiency, dropping torque when you least expect it. So, if you’re picking a motor, think about your setup. Need steady power for a sanitary dispenser? Voltage and design matter. Building a robot? Don’t sleep on current and gearing. These factors affecting DC motor torque are your toolkit for getting it just right.

Why DC Motor Torque Matters in Real Life

You might be thinking, “Okay, torque sounds cool, but why should I care?” Well, DC motor torque isn’t just some nerdy spec on a datasheet—it’s the secret sauce behind a ton of stuff you use every day. From the whir of a smart home gadget to the precision of a medical device, torque is what makes these things work smoothly. Let’s look at some real-life DC motor torque applications to see why it’s such a big deal.

Take smart homes, for example. Those motorized blinds that adjust with a tap on your phone? They rely on just the right amount of torque to glide up and down without jerking or stalling. Too little, and they’re stuck; too much, and you’re replacing snapped cords. Or think about robotics. A robot arm picking up a delicate circuit board needs torque that’s strong yet controlled—Etonm Motor’s micro DC motors are champs at this, by the way. We once had a customer who needed a custom torque setup for a sanitary dispenser—it had to push out soap reliably without wasting a drop. Nailed it with a worm gear motor tweak.

Then there’s vending machines. Ever had one drop your snack halfway and leave you hanging? That’s a torque fail. The motor needs enough twist to turn the spiral without overdoing it. And in medical care, like infusion pumps, torque keeps the flow steady—precision here isn’t just convenient, it’s critical. Want to explore more motor options for your project? Check out our micro DC motor lineup for some inspiration. Bottom line: DC motor torque applications are everywhere, quietly powering the world—one spin at a time.

How to Measure DC Motor Torque (And Why You Should)

By now, you’re probably sold on why torque matters—but how do you know if your motor’s got the right twist for the job? That’s where measuring DC motor torque comes in. It’s not just for engineers in lab coats; anyone picking a motor can benefit from a quick check. Let’s break it down and see why it’s worth the effort.

The simplest way to measure torque is with a dynamometer—a fancy word for a tool that tests how much force a motor can crank out. You hook the motor up, let it spin against a load, and the dynamometer spits out a number, usually in Newton-meters (Nm) or ounce-inches. No dynamometer lying around? You can get a rough idea by checking the motor’s spec sheet—look for torque ratings tied to voltage and current. For a hands-on tweak, some pros even use a pulley and weight setup to feel it out manually (just don’t tell OSHA I suggested that).

Why bother? Because picking the wrong torque is like buying shoes that don’t fit—uncomfortable and a waste of time. Too little torque, and your robotics project stalls mid-move. Too much, and you’re burning cash on overkill power. At Etonm Motor, we’ve seen customers dodge headaches by nailing this step—matching torque to tasks like powering a security lock or a vending machine gear.

Conclusion

So, there you have it—DC motor torque in a nutshell. It’s the twisting force that powers everything from your smart home gadgets to robotic arms, and it’s a lot less mysterious once you break it down. We’ve covered what it is, how it works, what tweaks it, and why it’s a game-changer in real life. Plus, you’ve got a handy tip on measuring it to make sure your motor’s up to the task. Pretty cool for something that just spins, right?

Torque might not be the flashiest part of a motor, but it’s the unsung hero that keeps things moving smoothly. Whether you’re tinkering with a DIY project or designing the next big thing, getting torque right can save you time, money, and a whole lot of frustration. Need a motor with the perfect twist for your idea? Swing by Etonm Motor’s product catalog to explore our custom solutions—planetary gear motors, micro DC motors, you name it. Or drop us a line—we’d love to help you spin your plans into action!

Related Reading

- Outrunner vs. Inrunner: Which Brushless DC Motor Fits Your Needs?

- What is Electronic Speed Control (ESC) for Brushless DC Motors?

- Brushless DC Motor vs. Servo Motor: What’s the Difference?

- How to Increase Torque in Brushless DC Motors: A Practical Guide

- BLDC Motor Speed Control: Methods, Tips & Applications

- What Are the Key Advantages of Brushless Motors?

- How Does a Brushless DC Motor Work? A Complete Guide to BLDC Motors

- What is KV Rating in Brushless Motors and How to Calculate It?

- What are the Components of Brushless DC Motor? A Comprehensive Guide

- What Factors Affect the Performance of Brushless Motors? A Comprehensive Guide

- The Ultimate Guide to Brushless DC Motors: Types, Applications, and Benefits

- 12V DC Motor High Torque Low RPM Performance

- AC Motors vs DC Motors: Which is Best for Your Application?

- 12V High Torque DC Motors: A Complete Guide To Power And Performance

- High Torque 12V DC Motor 2000 RPM | Custom 8mm Shaft Motors