Learn what KV rating means for brushless motors, why it matters, and how to calculate it. Discover how this crucial parameter impacts motor performance in applications like robotics, smart home devices, and more.

Table of Contents

Introduction to KV Rating in Brushless Motors

Alright, so when we’re talking about Brushless Motors – you might also hear them called BLDC Motors or Brushless DC Motors – the real trick is getting a good grasp on their specs. That’s how you make sure you pick the perfect motor for whatever you need it for. One of the most critical parameters to consider is the KV rating. But what exactly is KV rating, and why does it matter?

In simple terms, the KV rating of a brushless motor tells you how fast the motor will spin for every volt of electricity you apply. For example, a motor with a KV rating of 1000 will rotate at 1000 RPM (revolutions per minute) when 1 volt is supplied under no-load conditions. This rating is not just a number—it’s a gateway to understanding the motor’s performance, including its speed, torque, and efficiency.

Brushless motors are widely used in applications like robotics, smart home devices, medical equipment, and UAVs (unmanned aerial vehicles). Whether you’re designing a high-speed drone or a torque-heavy robotic arm, the KV rating plays a pivotal role in ensuring your motor meets the demands of your project. A high KV motor might be perfect for applications requiring high speed, while a low KV motor could be the better choice for tasks needing more torque.

In this article, we’ll dive deeper into what KV rating means, how to calculate it, and why it’s so important for your brushless motor applications. By the end, you’ll have a clear understanding of how to choose the right KV rating for your needs—and how Etonm Motor can help you find the perfect motor solution.

What is KV Rating in a Brushless Motor?

If you’ve ever wondered how to predict the performance of a Brushless Motor (or BLDC Motor), the KV rating is one of the first things you should look at. But what exactly does this term mean, and how does it influence your motor’s behavior?

The KV rating of a brushless motor is a measure of its RPM (revolutions per minute) per volt under no-load conditions. In other words, it tells you how fast the motor will spin when a specific voltage is applied. For example, a motor with a KV rating of 1500 will rotate at 1500 RPM when 1 volt is supplied. If you increase the voltage to 12 volts, the motor will spin at 18,000 RPM (1500 x 12).

How Does KV Rating Affect Motor Performance?

The KV rating is more than just a number—it’s a key indicator of how your motor will perform in real-world applications. Here’s how it works:

- High KV Motors: Motors with a high KV rating (e.g., 3000-5000) are designed for high-speed applications. They spin faster but produce less torque. These motors are ideal for lightweight, fast-moving devices like racing drones or small robotic arms.

- Low KV Motors: Motors with a low KV rating (e.g., 100-500) are built for high-torque applications. They spin slower but can handle heavier loads. These motors are perfect for applications like electric valves, conveyor belts, or heavy-duty robotics.

The Role of Winding Turns and Poles

The KV rating is closely tied to the motor’s internal design, particularly the number of winding turns and poles:

- Motors with more winding turns typically have a lower KV rating. They generate higher torque but operate at lower speeds.

- Motors with fewer winding turns have a higher KV rating. They achieve higher speeds but produce less torque.

Similarly, the number of poles in the motor also affects the KV rating. Motors with more poles tend to have a lower KV rating and are better suited for low-speed, high-torque applications. On the other hand, motors with fewer poles have a higher KV rating and are ideal for high-speed, low-torque tasks.

Why Does KV Rating Matter?

Understanding the KV rating is crucial because it helps you match the motor to your specific application. For instance:

- If you’re building a drone, you’ll need a high KV motor to achieve the rapid spin required for small propellers.

- If you’re designing an electric valve or a vending machine, a low KV motor will provide the torque needed to handle mechanical resistance.

In short, the KV rating is a fundamental parameter that influences everything from speed and torque to efficiency and power output. By understanding it, you can make smarter decisions when selecting a brushless motor for your project.

Why is KV Rating Important?

Now that we’ve covered what the KV rating is and how it’s defined, you might be wondering: Why does it matter so much? The answer lies in its direct impact on the performance and suitability of a Brushless Motor (or BLDC Motor) for specific applications. Let’s dive deeper into why the KV rating is a critical factor in motor selection.

1. Matching Motor Performance to Application Needs

The KV rating is a key indicator of how a motor will behave under different conditions. Here’s why it’s so important:

- Speed vs. Torque Trade-Off: The KV rating determines whether a motor is optimized for high speed or high torque. For example:

- A high KV motor (e.g., 3000-5000) is ideal for applications requiring rapid rotation, such as racing drones or high-speed fans.

- A low KV motor (e.g., 100-500) is better suited for tasks that demand high torque, such as electric valves, conveyor belts, or robotic arms.

Choosing the wrong KV rating can lead to inefficiency, overheating, or even motor failure. For instance, using a high KV motor for a high-torque application could cause the motor to stall or draw excessive current.

2. Efficiency and Power Consumption

The KV rating also affects the motor’s efficiency and power consumption:

- High KV Motors: These motors typically operate at higher speeds but may consume more current, especially under load. They are best used in applications where speed is prioritized over torque.

- Low KV Motors: These motors are more efficient in high-torque scenarios, as they can handle heavier loads without drawing excessive current. They are ideal for applications where power efficiency and durability are critical.

3. Real-World Applications of KV Rating

To better understand the importance of KV rating, let’s look at a few examples:

- Drones and UAVs: In the world of drones, KV rating plays a crucial role in determining the type of propeller and flight performance. High KV motors are used for lightweight, fast-spinning propellers in racing drones, while low KV motors are preferred for larger, slower-spinning propellers in heavy-lift drones.

- Smart Home Devices: In devices like automatic curtains or sanitary dispensers, low KV motors are often used to ensure smooth, quiet operation with sufficient torque to handle mechanical resistance.

- Industrial Automation: In applications like electric valves or vending machines, low KV motors provide the necessary torque to operate reliably under constant load.

4. Customization and Optimization

At Etonm Motor, we understand that every application is unique. That’s why we offer custom brushless motors tailored to your specific needs. Whether you need a high KV motor for speed or a low KV motor for torque, our team can help you find the perfect solution. By understanding the KV rating and its implications, you can make informed decisions that optimize performance and efficiency.

How to Calculate the KV Rating of a Brushless Motor

Now that we’ve established the importance of the KV rating in Brushless Motors (or BLDC Motors), let’s dive into the practical side: how to calculate it. Whether you’re designing a custom motor or selecting one for a specific application, understanding how to determine the KV rating is essential.

The Basic Formula for KV Rating

The KV rating of a brushless motor is calculated using the following formula:

KV = RPM / Voltage

Here’s what each term means:

- RPM: The motor’s rotational speed in revolutions per minute (measured under no-load conditions).

- Voltage: The voltage applied to the motor.

For example, if a motor spins at 12,000 RPM when 12 volts are applied, its KV rating would be:

KV = 12,000 RPM / 12V = 1000 KV.

Step-by-Step Guide to Calculating KV Rating

To calculate the KV rating accurately, follow these steps:

- Measure the Motor’s RPM: Use a tachometer or an RPM sensor to measure the motor’s speed under no-load conditions. Ensure the motor is running freely without any external load.

- Measure the Applied Voltage: Use a multimeter to measure the voltage supplied to the motor. Make sure the voltage is stable during the measurement.

- Apply the Formula: Plug the RPM and voltage values into the formula KV = RPM / Voltage to calculate the KV rating.

Accounting for Counter-Electromotive Force (EMF)

For a more precise calculation, you’ll need to consider the counter-electromotive force (EMF). This is the voltage generated by the motor as it spins, which opposes the applied voltage. The relationship between KV rating and EMF can be expressed as:

KV = RPM / (Peak Voltage * 0.95)

Here’s how to incorporate EMF into your calculation:

- Measure the Peak Voltage: Use an oscilloscope or a high-precision multimeter to measure the peak voltage across the motor terminals.

- Apply the Correction Factor: Multiply the peak voltage by 0.95 to account for real-world deviations from the theoretical model.

- Calculate the KV Rating: Use the adjusted formula to determine the KV rating.

Practical Example

Let’s say you measure a motor’s RPM at 10,000 and its peak voltage at 10.5V. Applying the correction factor, the calculation would be:

KV = 10,000 RPM / (10.5V * 0.95) = 10,000 / 9.975 ≈ 1002 KV.

Why Accurate KV Calculation Matters

Accurately calculating the KV rating ensures that you select the right motor for your application. For instance:

- If you’re building a drone, an accurate KV rating helps you match the motor to the propeller size and desired flight performance.

- In industrial automation, knowing the KV rating ensures the motor can handle the required load without overheating or stalling.

At Etonm Motor, we specialize in providing custom brushless motors with precise KV ratings tailored to your needs. Whether you’re working on a high-speed drone or a high-torque robotic arm, our team can help you find the perfect motor solution.

Factors Affecting KV Rating in Brushless Motors

While the KV rating is a fundamental parameter for Brushless Motors (or BLDC Motors), it’s not a fixed value that exists in isolation. Several factors influence the KV rating, and understanding these can help you make better decisions when selecting or designing a motor for your application. Let’s explore the key factors that affect KV rating.

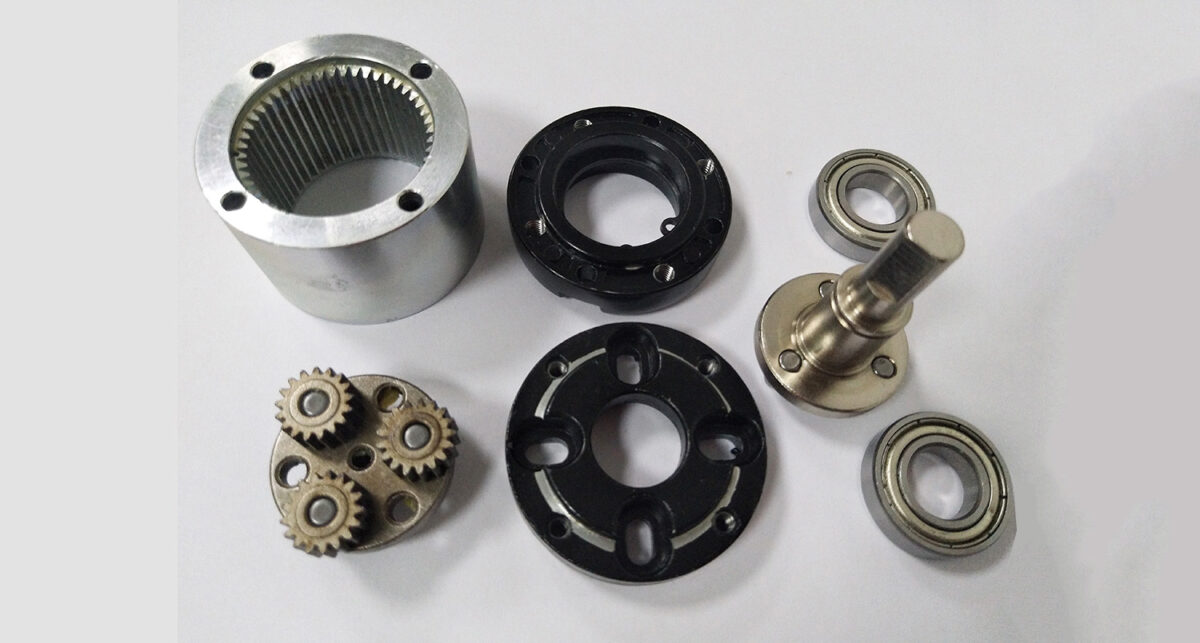

1. Number of Winding Turns

The number of winding turns in the motor’s coils is one of the most significant factors affecting the KV rating:

- More Winding Turns: Motors with more winding turns typically have a lower KV rating. These motors generate higher torque but operate at lower speeds. They are ideal for applications requiring high torque, such as electric valves or conveyor systems.

- Fewer Winding Turns: Motors with fewer winding turns have a higher KV rating. These motors achieve higher speeds but produce less torque, making them suitable for applications like drones or high-speed fans.

2. Number of Motor Poles

The number of poles in the motor also plays a crucial role in determining the KV rating:

- More Poles: Motors with more poles tend to have a lower KV rating. They are designed for low-speed, high-torque applications, such as industrial machinery or heavy-duty robotics.

- Fewer Poles: Motors with fewer poles have a higher KV rating. They are optimized for high-speed, low-torque tasks, such as UAVs or small robotic arms.

3. Magnet Strength

The strength of the magnets used in the motor affects its performance and KV rating:

- Stronger Magnets: Motors with stronger magnets can generate higher torque, which often results in a lower KV rating. These motors are ideal for applications requiring significant mechanical power.

- Weaker Magnets: Motors with weaker magnets may have a higher KV rating but produce less torque. They are better suited for lightweight, high-speed applications.

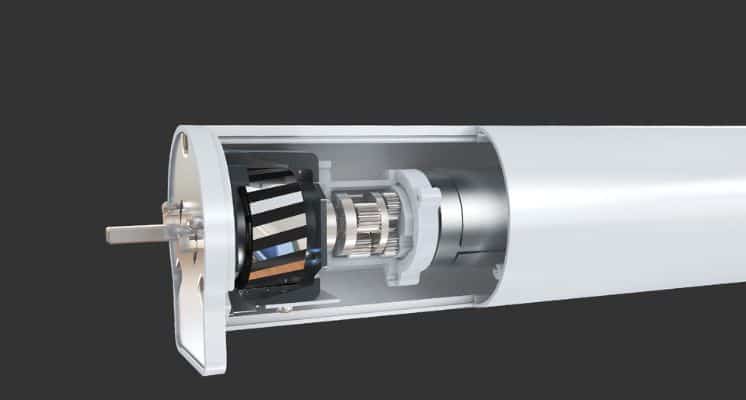

4. Motor Size and Design

The physical size and design of the motor also influence its KV rating:

- Larger Motors: Larger motors with more internal space can accommodate more winding turns and poles, resulting in a lower KV rating. These motors are often used in heavy-duty applications.

- Smaller Motors: Smaller motors typically have fewer winding turns and poles, leading to a higher KV rating. They are commonly used in compact, high-speed devices.

5. Temperature and Operating Conditions

External factors like temperature and operating conditions can also impact the KV rating:

- High Temperatures: Excessive heat can affect the motor’s performance, potentially altering its KV rating. It’s essential to ensure proper cooling and thermal management in high-temperature environments.

- Load Conditions: The KV rating is measured under no-load conditions. When a motor is under load, its actual performance may differ slightly due to factors like friction and mechanical resistance.

Why Understanding These Factors Matters

By understanding the factors that influence KV rating, you can:

- Optimize Motor Selection: Choose a motor with the right KV rating for your specific application, whether it’s high-speed, high-torque, or something in between.

- Improve Efficiency: Select a motor that operates efficiently under your desired conditions, reducing energy consumption and extending the motor’s lifespan.

- Customize Motor Design: Work with manufacturers like Etonm Motor to design custom brushless motors tailored to your unique requirements.

Choosing the Right KV Rating for Your Application

Now that we’ve explored what KV rating is, how to calculate it, and the factors that influence it, the next logical question is: How do you choose the right KV rating for your specific application? Whether you’re working on a drone, a robotic arm, or an electric valve, selecting the correct KV rating is crucial for optimal performance. Let’s break down the process of choosing the right KV rating.

1. Understand Your Application Requirements

The first step in selecting the right KV rating is to clearly define your application’s needs. Ask yourself:

- Do you need high speed or high torque?

- High-speed applications (e.g., drones, fans) typically require high KV motors.

- High-torque applications (e.g., conveyor belts, electric valves) are better suited for low KV motors.

- What is the operating voltage?

- The KV rating is directly tied to voltage. Ensure the motor’s KV rating aligns with your system’s voltage to achieve the desired RPM.

- What is the load like?

- Heavy loads require motors with higher torque, which usually means a lower KV rating. Light loads can work well with higher KV motors.

2. Match KV Rating to Propeller or Gear Ratio

For applications like drones or robotics, the KV rating must be matched to the propeller size or gear ratio:

- High KV Motors: These are ideal for small propellers or low gear ratios, where high speed is needed. For example, racing drones use high KV motors to achieve rapid propeller spin.

- Low KV Motors: These are better for large propellers or high gear ratios, where torque is more important than speed. For instance, heavy-lift drones use low KV motors to handle larger propellers and heavier payloads.

3. Consider Efficiency and Power Consumption

Efficiency is another critical factor when choosing a KV rating:

- High KV Motors: While they offer high speed, they may consume more current, especially under load. Ensure your power supply can handle the current draw.

- Low KV Motors: These are more efficient in high-torque scenarios, as they can handle heavier loads without drawing excessive current. They are ideal for applications where energy efficiency is a priority.

4. Real-World Examples of KV Rating Selection

Let’s look at a few examples to illustrate how KV rating selection works in practice:

- Drones and UAVs:

- For a racing drone, you might choose a motor with a KV rating of 2500-3000 to achieve high speeds with small propellers.

- For a heavy-lift drone, a motor with a KV rating of 500-800 would be more appropriate, as it provides the necessary torque for larger propellers and heavier payloads.

- Robotics:

- A robotic arm requiring precise, slow movements would benefit from a low KV motor (e.g., 100-300) to ensure smooth operation and high torque.

- A small, fast-moving robot might use a high KV motor (e.g., 2000-3000) to achieve quick, agile movements.

- Industrial Applications:

- For an electric valve or vending machine, a low KV motor (e.g., 100-500) would provide the torque needed to handle mechanical resistance reliably.

5. Consult with Experts for Custom Solutions

If you’re unsure about the right KV rating for your application, don’t hesitate to consult with experts. At Etonm Motor, we specialize in providing custom brushless motors tailored to your specific needs. Whether you need a high KV motor for speed or a low KV motor for torque, our team can help you find the perfect solution.

Conclusion – Mastering KV Rating for Optimal Brushless Motor Performance

By now, you should have a solid understanding of what KV rating is, how to calculate it, and why it’s such a critical factor in the performance of Brushless Motors (or BLDC Motors). Whether you’re designing a high-speed drone, a torque-heavy robotic arm, or an efficient electric valve, the KV rating plays a pivotal role in ensuring your motor meets the demands of your application.

Key Takeaways

Let’s recap the most important points covered in this article:

- KV Rating Defined: The KV rating of a brushless motor indicates its RPM per volt under no-load conditions. It’s a key parameter that influences both speed and torque.

- How to Calculate KV Rating: Use the formula KV = RPM / Voltage to determine the KV rating. For greater accuracy, consider the counter-electromotive force (EMF) and apply a correction factor.

- Factors Affecting KV Rating: The number of winding turns, motor poles, magnet strength, and motor size all influence the KV rating. Understanding these factors helps you select or design the right motor for your needs.

- Choosing the Right KV Rating: Match the KV rating to your application’s requirements, whether you need high speed, high torque, or a balance of both. Consider factors like propeller size, gear ratio, and power efficiency.

- Real-World Applications: From drones and robotics to industrial automation, the KV rating is a crucial consideration for optimizing motor performance in diverse fields.

Why This Knowledge Matters

Understanding KV rating isn’t just for engineers or motor enthusiasts—it’s for anyone who wants to make informed decisions about motor selection and performance. By mastering this concept, you can:

- Avoid Common Pitfalls: Choosing the wrong KV rating can lead to inefficiency, overheating, or even motor failure. With the right knowledge, you can avoid these issues.

- Optimize Performance: Whether you’re building a lightweight drone or a heavy-duty conveyor system, selecting the right KV rating ensures your motor operates at peak efficiency.

- Save Time and Money: By selecting the right motor from the start, you can reduce trial and error, minimize downtime, and extend the lifespan of your equipment.

Your Next Steps

If you’re ready to take your project to the next level, consider partnering with Etonm Motor. We specialize in providing custom brushless motors tailored to your specific needs. Whether you need a high KV motor for speed or a low KV motor for torque, our team of experts is here to help. Contact us today to discuss your requirements and discover how we can deliver the perfect motor solution for your application.

Related Reading and Helpful Resouces

- Understanding KV Rating in Brushless Motors

- Brushless DC Motor Troubleshooting: Common Issues and Solutions

- What are the Components of Brushless DC Motor? A Comprehensive Guide

- How to Choose the Right Brushless Motor for Your Drone: A Complete Guide

- What Factors Affect the Performance of Brushless Motors? A Comprehensive Guide

- AC Motors vs DC Motors: Which is Best for Your Application?

- Why BLDC Motors Are the Future of Electric Vehicles: A Complete Guide

- Top 5 Applications of Brushless DC Motors in Industrial Automation

- BLDC Motor vs Brushed Motor: Which is Better for Your Needs?