Discover why a DC motor controller is essential for optimizing the performance of Brushless DC Motors (BLDC Motors). Learn how it enhances efficiency, control, and longevity in various applications.

Table of Contents

Introduction

Brushless DC Motors (BLDC Motors) have become a cornerstone of modern technology, powering everything from smart home devices to advanced medical equipment. Their compact size, high efficiency, and reliability make them a preferred choice for applications where precision and durability are critical. However, to truly unlock the potential of a Brushless Motor, pairing it with a DC motor controller is essential.

A DC motor controller acts as the brain of the system, ensuring optimal performance by regulating speed, torque, and power consumption. Whether you’re designing a robotic arm, a vending machine, or a sanitary dispenser, integrating a controller with your BLDC Motor can significantly enhance efficiency, extend motor life, and reduce operational noise.

In this article, we’ll dive into the reasons why a DC motor controller is a must-have for Brushless DC Motors. From improving energy efficiency to enabling precise control in demanding environments, you’ll discover how this combination can elevate your designs to the next level. Let’s explore the transformative impact of DC motor controllers on BLDC Motors and why they are indispensable in today’s technology-driven world.

What is a BLDC Motor?

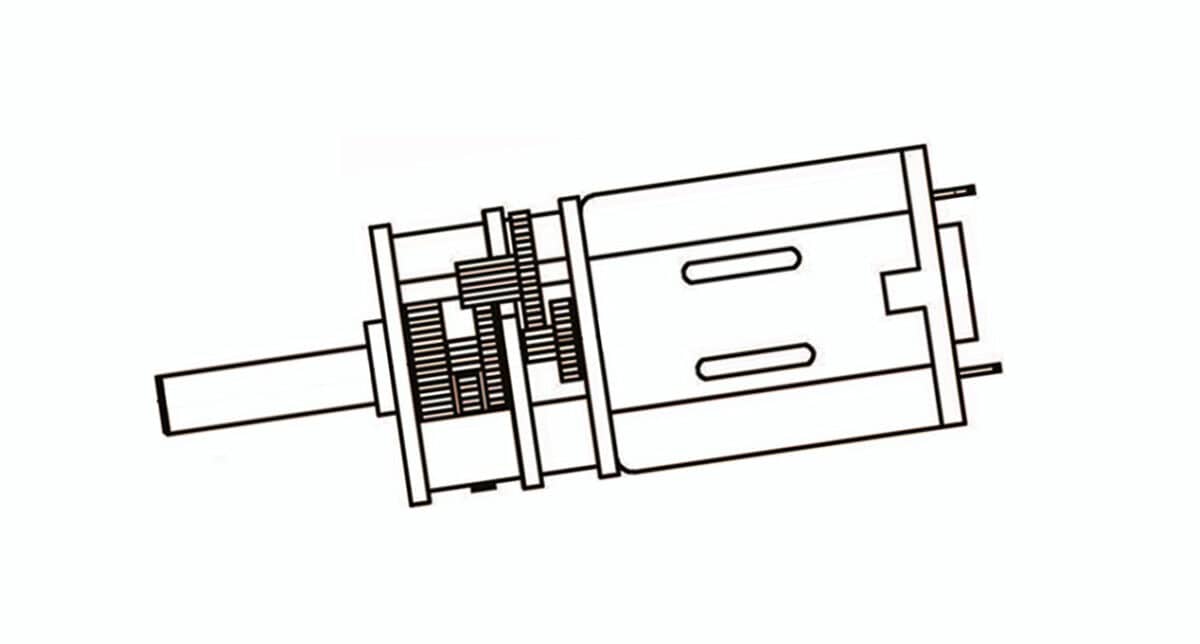

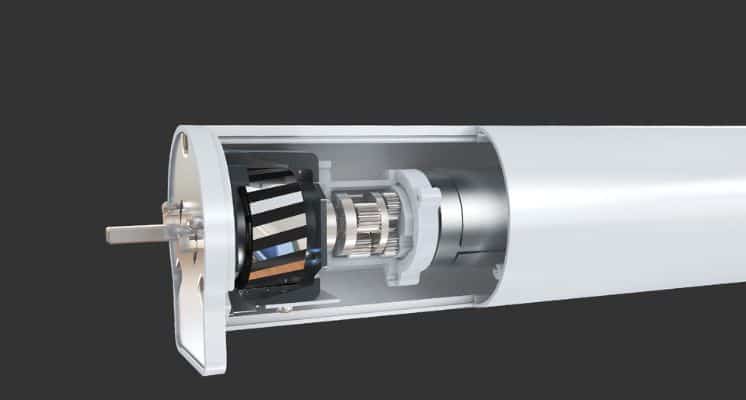

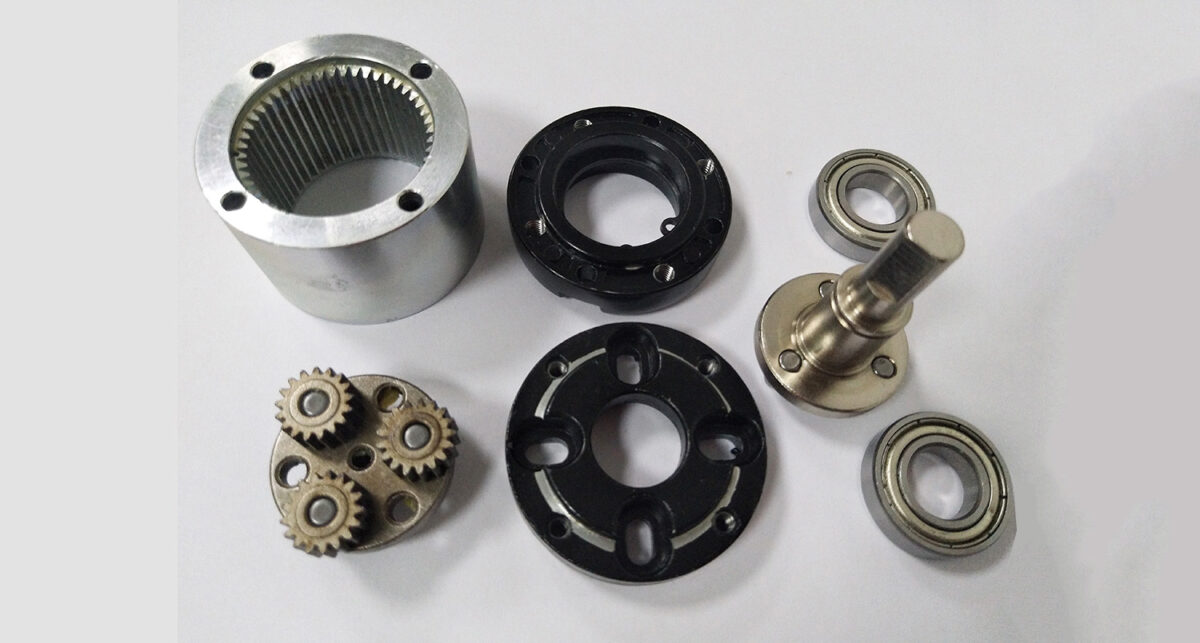

A Brushless DC Motor (BLDC Motor) is a type of electric motor that operates without the brushes found in traditional brushed motors. Instead of relying on mechanical commutation, BLDC Motors use electronic controllers to switch the current in the motor windings. This design eliminates the friction and wear associated with brushes, resulting in a motor that is more efficient, durable, and maintenance-free.

How Does a BLDC Motor Work?

BLDC Motors rely on a combination of permanent magnets and electronically controlled coils to generate motion. The controller determines the timing and sequence of current flow through the motor windings, creating a rotating magnetic field that drives the rotor. This electronic commutation allows for precise control over speed and torque, making BLDC Motors ideal for applications requiring high performance and reliability.

BLDC Motors vs. Brushed Motors

Compared to traditional brushed motors, BLDC Motors offer several advantages:

- Higher Efficiency: Without brushes causing friction, BLDC Motors convert more electrical energy into mechanical energy.

- Longer Lifespan: The absence of brushes reduces wear and tear, extending the motor’s operational life.

- Quieter Operation: Electronic commutation minimizes noise, making BLDC Motors suitable for noise-sensitive environments.

- Compact Design: BLDC Motors are often smaller and lighter, perfect for applications where space is limited.

Learn More about are differences between BLDC motors and brushed motors.

Applications of BLDC Motors

Thanks to their versatility and performance, BLDC Motors are widely used across various industries:

- Smart Home Devices: From automated blinds to HVAC systems, BLDC Motors provide quiet and efficient operation.

- Robotics: Precision control is critical in robotic arms, drones, and automated guided vehicles (AGVs).

- Medical Care: BLDC Motors power medical pumps, diagnostic equipment, and surgical tools, where reliability is paramount.

- Industrial Automation: They are used in conveyor systems, electric valves, and vending machines for consistent performance.

Learn more about BLDC motor applications

Why Use a DC Motor Controller for BLDC Motors?

While Brushless DC Motors (BLDC Motors) are inherently efficient and reliable, their performance can be significantly enhanced with the addition of a DC motor controller. A controller acts as the command center for the motor, ensuring it operates at peak efficiency while providing precise control over its functions. Here’s why a DC motor controller is indispensable for BLDC Motors:

1. Enhanced Efficiency

A DC motor controller optimizes the power delivered to the BLDC Motor, ensuring it runs at the most efficient operating point. By adjusting the voltage and current, the controller minimizes energy waste, which is especially important in battery-powered applications like portable medical devices or robotics. This efficiency not only reduces energy costs but also extends the runtime of devices.

2. Precise Speed and Torque Control

One of the standout features of a BLDC Motor is its ability to deliver precise control over speed and torque. A DC motor controller makes this possible by using advanced techniques like Pulse Width Modulation (PWM) to regulate the motor’s performance. Whether you need slow, precise movements in a robotic arm or high-speed operation in a drone, the controller ensures the motor responds accurately to your requirements.

3. Extended Motor Life

BLDC Motors are known for their durability, but a DC motor controller can further extend their lifespan. By managing the motor’s operation and preventing issues like overheating or overloading, the controller reduces wear and tear on the motor components. This is particularly important in applications where the motor operates continuously, such as in industrial automation or medical pumps.

4. Noise Reduction

In noise-sensitive environments like smart homes or medical facilities, minimizing operational noise is crucial. A DC motor controller helps achieve this by ensuring smooth and consistent motor operation. By eliminating abrupt starts and stops, the controller reduces vibrations and acoustic noise, making BLDC Motors ideal for applications like HVAC systems or diagnostic equipment.

5. Improved Safety and Reliability

A DC motor controller adds an extra layer of safety by incorporating features like overcurrent protection, thermal management, and fault detection. These safeguards prevent damage to the motor and the connected system, ensuring reliable operation even in demanding conditions. For example, in electric valves or security systems, a controller ensures the motor operates flawlessly without risking failure.

6. Customization for Specific Applications

Every application has unique requirements, and a DC motor controller allows for customization to meet those needs. Whether you’re designing a compact robotic device or a high-torque industrial machine, the controller can be tailored to deliver the exact performance characteristics required.

Key Features of a DC Motor Controller

A DC motor controller is the backbone of any Brushless DC Motor (BLDC Motor) system, providing the intelligence needed to optimize performance. But what exactly makes a DC motor controller so effective? Let’s break down the key features that set it apart and explain how they contribute to the superior operation of BLDC Motors.

1. Pulse Width Modulation (PWM)

PWM is a fundamental feature of most DC motor controllers. It works by rapidly switching the power supply on and off, effectively controlling the average voltage delivered to the motor. This allows for precise regulation of motor speed and torque, making it ideal for applications like robotics or electric valves where fine-tuned control is essential. PWM also improves energy efficiency by reducing power loss.

2. Feedback Systems

Many advanced DC motor controllers incorporate feedback mechanisms such as encoders or Hall-effect sensors. These sensors provide real-time data on the motor’s position, speed, and torque, enabling the controller to make instant adjustments. This closed-loop control ensures consistent performance, even under varying loads or conditions. For example, in a robotic arm, feedback systems help maintain precise movements.

3. Thermal Management

BLDC Motors often operate in compact spaces, which can lead to heat buildup. A DC motor controller includes thermal management features to prevent overheating. By monitoring temperature and adjusting power output, the controller protects the motor from damage and ensures reliable operation. This is especially critical in applications like medical devices or industrial automation, where downtime is not an option.

4. Overcurrent and Overvoltage Protection

Electrical faults like overcurrent or overvoltage can damage both the motor and the controller. To mitigate this risk, DC motor controllers are equipped with protection circuits that detect and respond to abnormal conditions. For instance, if a motor draws too much current, the controller can shut it down or reduce power to prevent damage. This feature is invaluable in high-stakes environments like security systems or electric valves.

5. Programmability and Customization

One of the most powerful aspects of a DC motor controller is its programmability. Many controllers allow users to customize parameters such as acceleration, deceleration, and maximum speed. This flexibility makes them suitable for a wide range of applications, from slow-moving sanitary dispensers to high-speed vending machines. At Etonm Motor, we specialize in providing tailored solutions to meet your specific needs.

6. Compact and Lightweight Design

Given the small size of BLDC Motors, their controllers are designed to be equally compact and lightweight. This makes them easy to integrate into space-constrained applications like drones or portable medical devices. Despite their small size, these controllers pack a punch, delivering robust performance without compromising on features.

7. Communication Interfaces

Modern DC motor controllers often include communication interfaces such as UART, I2C, or CAN bus. These interfaces allow the controller to communicate with other components in the system, enabling advanced functionalities like remote monitoring or automated control. For example, in a smart home system, a controller can receive commands from a central hub to adjust motor settings.

Applications of BLDC Motors with Controllers

Brushless DC Motors (BLDC Motors) paired with DC motor controllers are transforming industries by delivering unmatched efficiency, precision, and reliability. Their compact size and advanced control capabilities make them ideal for a wide range of applications. Let’s explore some of the most common and innovative uses of BLDC Motors with controllers across various sectors.

1. Smart Home Devices

In the era of smart homes, BLDC Motors with controllers are at the heart of many automated systems. For example:

- Automated Blinds: Controllers enable smooth and quiet operation, allowing blinds to open and close at scheduled times or in response to sunlight.

- HVAC Systems: BLDC Motors optimize airflow in heating and cooling systems, improving energy efficiency and comfort.

- Smart Appliances: From washing machines to vacuum cleaners, BLDC Motors provide reliable and efficient performance.

2. Robotics

Robotics demands precision, and BLDC Motors with controllers deliver just that. Applications include:

- Robotic Arms: Controllers ensure precise movements, making them ideal for assembly lines or surgical robots.

- Drones: BLDC Motors provide the high-speed, efficient propulsion needed for stable and agile flight.

- Autonomous Guided Vehicles (AGVs): These motors enable smooth navigation and load handling in warehouses and factories.

3. Medical Care

In the medical field, reliability and precision are non-negotiable. BLDC Motors with controllers are used in:

- Medical Pumps: Controllers ensure accurate dosing and consistent operation in infusion pumps or dialysis machines.

- Diagnostic Equipment: BLDC Motors power imaging devices and lab equipment, delivering quiet and vibration-free performance.

- Surgical Tools: High-precision motors enable delicate procedures with minimal risk.

4. Industrial Automation

BLDC Motors are revolutionizing industrial automation by providing efficient and reliable motion control. Examples include:

- Conveyor Systems: Controllers regulate speed and torque, ensuring smooth material handling.

- Electric Valves: BLDC Motors enable precise control of fluid flow in pipelines or irrigation systems.

- Packaging Machinery: These motors ensure consistent performance in high-speed packaging lines.

5. Vending Machines

Vending machines rely on BLDC Motors for quiet and reliable operation. Controllers ensure:

- Accurate Product Dispensing: Motors deliver the right amount of force to release products without jamming.

- Energy Efficiency: BLDC Motors reduce power consumption, making vending machines more cost-effective to operate.

6. Security Systems

In security applications, reliability is key. BLDC Motors with controllers are used in:

- Surveillance Cameras: Motors enable smooth pan-tilt-zoom (PTZ) movements for optimal coverage.

- Automatic Doors: Controllers ensure secure and efficient operation in access control systems.

7. Electric Vehicles and Mobility

BLDC Motors are also making waves in the electric vehicle (EV) industry. Applications include:

- E-Bikes and Scooters: Controllers optimize motor performance for longer battery life and smoother rides.

- Wheelchairs and Mobility Aids: BLDC Motors provides reliable and quiet operation for enhanced user comfort.

Choosing the Right DC Motor Controller for Your BLDC Motor

Selecting the right DC motor controller for your Brushless DC Motor (BLDC Motor) is crucial to achieving optimal performance and reliability. With so many options available, it can be challenging to determine which controller best suits your application. Here are the key factors to consider when making your choice:

1. Voltage and Current Ratings

The first step is to ensure the controller is compatible with your motor’s voltage and current requirements. Check the motor’s specifications and choose a controller that can handle the same or higher ratings. For example, if your BLDC Motor operates at 24V and draws 5A, the controller should support at least these values. Exceeding the ratings can lead to overheating or damage.

2. Control Features

Different applications require different levels of control. Consider the following features:

- Speed Control: If your application requires variable speeds, look for a controller with PWM or analog input capabilities.

- Torque Control: For applications like robotics or electric valves, precise torque control is essential.

- Direction Control: Ensure the controller supports forward and reverse operation if needed.

3. Feedback and Sensor Compatibility

If your BLDC Motor uses sensors (e.g., Hall-effect sensors or encoders) for feedback, make sure the controller is compatible with these components. Sensorless controllers are also available but may not offer the same level of precision.

4. Programmability

For advanced applications, a programmable controller is a must. Look for controllers that allow you to customize parameters such as acceleration, deceleration, and maximum speed. This flexibility is particularly useful in robotics or industrial automation.

5. Thermal Management

Heat is a common issue in compact motor systems. Choose a controller with built-in thermal protection to prevent overheating. Features like temperature sensors and automatic power reduction can extend the lifespan of both the motor and the controller.

6. Size and Form Factor

Given the small size of BLDC Motors, the controller should also be compact and lightweight. Ensure it can fit within the design constraints of your application, whether it’s a drone, medical device, or smart home appliance.

7. Communication Interfaces

Modern controllers often include communication interfaces like UART, I2C, or CAN bus. These allow the controller to integrate with other systems, enabling advanced functionalities such as remote monitoring or automated control. For example, in a smart home system, a controller with UART can communicate with a central hub.

8. Reliability and Durability

In demanding environments like industrial automation or medical care, reliability is non-negotiable. Look for controllers with robust construction and protection features like overcurrent, overvoltage, and short-circuit protection.

9. Customization Options

Every application is unique, and off-the-shelf controllers may not always meet your specific needs. At Etonm Motor, we specialize in providing customized solutions tailored to your requirements. Whether you need a specific voltage rating, unique control features, or a compact design, we can help.

10. Cost and Support

While cost is always a consideration, it’s important to balance price with quality and support. Investing in a high-quality controller from a reputable manufacturer like Etonm Motor ensures long-term reliability and access to technical support.

Conclusion

Brushless DC Motors (BLDC Motors) have revolutionized industries with their efficiency, reliability, and compact design. However, to truly unlock their potential, pairing them with a DC motor controller is essential. From enhancing energy efficiency and precise control to extending motor life and reducing noise, the benefits of using a controller are undeniable.

In this article, we’ve explored:

- The working principles and advantages of BLDC Motors.

- Why a DC motor controller is crucial for optimizing their performance.

- The key features of a controller, such as PWM, feedback systems, and thermal management.

- Real-world applications in smart homes, robotics, medical care, and more.

- How to choose the right controller for your specific needs.

Whether you’re designing a cutting-edge robotic system, a quiet and efficient smart home device, or a reliable medical pump, the combination of a BLDC Motor and a DC motor controller can elevate your project to new heights.

At Etonm Motor, we specialize in providing high-quality Brushless Motors and customized DC motor controllers tailored to your unique requirements. Our expertise ensures that you get the perfect solution for your application, whether it’s for industrial automation, electric valves, or vending machines.

Take the Next Step

Ready to power your innovations with the best in motor technology? Explore our range of BLDC Motors and controllers today. If you have any questions or need assistance, our team is here to help. Share this article with your network, leave a comment below, or contact us to learn more about how we can support your projects.

Let’s drive the future of technology together—one motor at a time!

Related Reading

- What is KV Rating in Brushless Motors and How to Calculate It?

- Brushless DC Motor Troubleshooting: Common Issues and Solutions

- What are the Components of Brushless DC Motor? A Comprehensive Guide

- What Factors Affect the Performance of Brushless Motors? A Comprehensive Guide

- What Are the Key Advantages of Brushless Motors?